I am Kang Kang, a technical consultant at Shandong Hychron EnergyTech Co., Ltd.

Our company has been deeply involved in the water treatment industry for 20 years and has served over 30 clients. After implementing my wastewater treatment solutions, our clients have achieved compliance with the new discharge standards and reduced operational costs by 15%. Their successful cases have been widely referenced in the industry. According to my research, my solutions can remove 90% of pollutants while reducing wastewater treatment costs, which not only meets environmental requirements but also significantly improves the economic benefits for businesses.

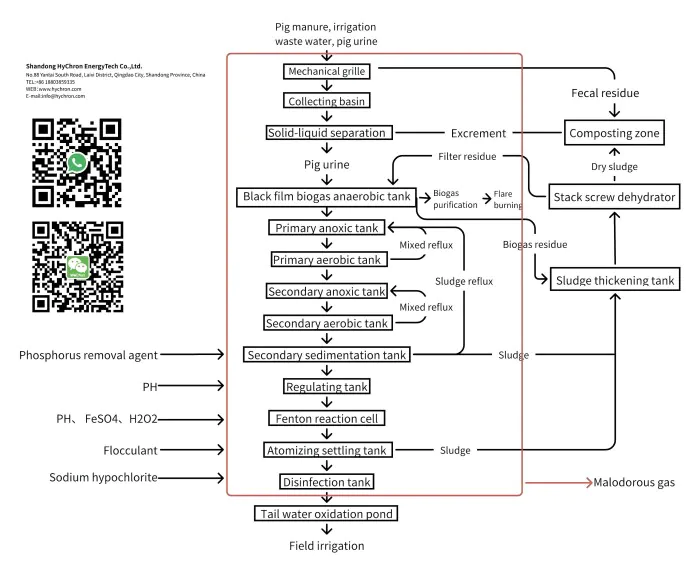

Now, let’s take a look at the basic treatment process and key chemicals used in pig farm wastewater treatment.

Feel free to contact us for a one-on-one solution.

Pig farm sewage treatment process:

The treatment process uses biological treatment technology, including “Pre-treatment + Black Membrane Biogas Tank + Two-Stage A/O + Fenton Reaction + Disinfection + Oxidation Pond” as the core.

The system includes a collection tank, adjustment tank, black membrane biogas tank, two-stage A/O reaction tank, sedimentation tank, Fenton reaction tank, physical-chemical sedimentation tank, disinfection tank, sludge concentration tank, medication room, control room, and tailwater oxidation pond. The tanks have concrete structures at the bottom and are designed to prevent leakage.

Pig farm wastewater treatment process is shown below:

Main wastewater management for pig farms process steps:

1- Pre-treatment

- Collection Tank: Collects wastewater from each pigsty and sends it to the solid-liquid separator.

- Solid-Liquid Separator: Removes suspended solids (such as pig hair, large feed particles, and pig manure), reducing the load on subsequent treatments and the risk of pump clogging. The separated wastewater enters the adjustment tank.

2- Biological Treatment

- Adjustment Tank: The pre-treated wastewater enters the adjustment tank, where it is homogenized before being pumped to the black membrane biogas tank.

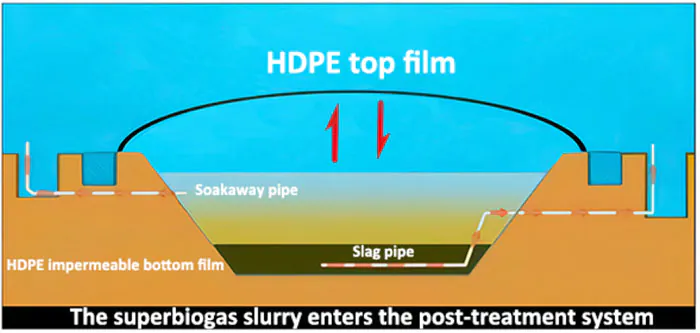

- Black Membrane Biogas Tank: This tank, also known as a fully enclosed black membrane anaerobic tank, allows organic materials like manure to ferment at room temperature, producing biogas. The tank is built with high-quality materials, is cost-effective, and has a long retention time for wastewater, which enhances biogas production.

- Two-Stage A/O Nitrogen Removal System: After the black membrane biogas tank, the wastewater undergoes a two-stage A/O treatment to remove COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand). The first stage (anoxic tank) uses facultative bacteria to break down long-chain organic molecules into smaller, biodegradable components. The second stage (aerobic tank) further breaks down these components into CO₂ and water, also removing nitrogen.

- Secondary Sedimentation Tank: Before entering the Fenton reaction tank, the wastewater goes through a secondary sedimentation tank to remove excess aerobic bacteria and settle out suspended solids.

3- Fenton Reaction:

- This advanced oxidation process uses hydrogen peroxide (H₂O₂) and ferrous sulfate (Fe²⁺) to generate hydroxyl radicals, which are highly effective in breaking down organic pollutants. The Fenton-treated water is neutralized, aerated, and sent to the coagulation tank.

4- Coagulation/Flocculation and Final Sedimentation

After Fenton treatment, the wastewater contains a lot of dead bacteria. Coagulants (PAC) and flocculants (PAM) are added to form large flocs that can settle by gravity.

5- Disinfection:

- The treated water undergoes disinfection with sodium hypochlorite to kill any remaining pathogens before being returned to the oxidation pond for further treatment and recycling, in line with planting schedules.

6- Sludge Concentration and Compression:

- The sludge is concentrated in a gravity thickening tank and then further compressed using a screw press. The resulting dry sludge is sent to a composting area.

Best chemicals for pig farm wastewater treatment:

Chemical Information:

| NO. | English Name | CAS NO. | Chemical Formula |

|---|---|---|---|

| 1 | Peracetic acid | 79-21-0 | C2H4O3 |

| 2 | Sodium hydroxide | 1310-73-2 | NaOH |

| 3 | Sodium hypochlorite | 7681-52-9 | NaClO |

| 4 | Polyacrylamide | 2594446 | (C3H5NO)n |

| 5 | Aluminum chloride | 1327-41-9 | [Al2(OH)nCl6-n·xH2O]m (m≤10, n=1~5) |

| 6 | Ferrous sulfate | 7720-78-7 | FeSO4 |

| 7 | Hydrogen peroxide | 7722-84-1 | H2O2 |

Physical and chemical properties:

| NO. | Name | Physicochemical Properties |

|---|---|---|

| 1 | Peracetic acid | C₂H₄O₃, a colorless liquid with a strong pungent odor. Soluble in water, ethanol, ether, and sulfuric acid. Used as a bleaching agent, catalyst, oxidizer, and disinfectant. High chemical reactivity and poses risks of combustion and explosion when mixed with organic matter, reducing agents, or flammable materials. Explosive when exposed to heat, open flame, or friction. |

| 2 | Sodium hydroxide | NaOH, also known as caustic soda or lye, is a strongly corrosive alkali. Usually found in flake or solid form, highly soluble in water with heat released during dissolution. Absorbs moisture and carbon dioxide from the air. Corrosive and irritating to skin, eyes, and respiratory system. Should be labeled as a “corrosive material.” |

| 3 | Embacterium | Effective Microorganisms (EM), a preparation of over 80 microorganisms, mainly photosynthetic bacteria, lactic acid bacteria, yeast, and actinomycetes. Used for ecological agriculture and sustainable development. Forms beneficial microbial communities to control pathogens. Widely applied in agriculture, aquaculture, environmental protection, and more. |

| 4 | Sodium hypochlorite | A yellowish solution or white powder with a chlorine-like odor. Produces toxic, corrosive fumes upon high thermal decomposition. Corrosive. |

| 5 | PAM (Polyacrylamide) | A linear polymer available in dry powder or colloidal form. White powder or small particles, density of 1.32g/cm³, insoluble in most organic solvents except a few polar ones like acetic acid. Commonly used as a non-ionic polymer flocculant in water treatment. |

| 6 | PAC (Polyaluminum chloride) | Chemical formula Al₂Cln(OH)₆-n. Yellow or light yellow solid; solution appears colorless or yellow-brown. Occasionally contains impurities that make it gray-black. Widely used for water treatment. |

| 7 | Deodorant | Microbial antibacterial deodorant with a strong degradation effect on ammonia and hydrogen sulfide odors. Composed of citric acid, malic acid, lactic acid, and biological enzymes produced by lactic acid bacteria, yeast, and photosynthetic bacteria. Degradation rates: 92.6% for ammonia and 89.0% for hydrogen sulfide within 10 minutes. |

| 8 | Ferrous sulfate | A blue-green monoclinic crystal. Oxidizes to brown basic iron sulfate in moist air. Soluble in water but almost insoluble in ethanol. Commonly known as “green vitriol.” Storage: cool, ventilated, and dry warehouse. |

| 9 | Hydrogen peroxide | Chemical formula H₂O₂, stored in 30% or 60% aqueous solution. Highly oxidizing and weakly acidic. Chemically unstable. |