Polyacrylamide (PAM) is vital in water treatment, papermaking, oil drilling, and more. But many companies overlook a key factor when choosing PAM: molecule size. Different sizes affect how well PAM dissolves, its thickness, and clumping power—directly impacting results and costs.

How does molecular weight affect the properties of PAM?

Molecule size refers to the total mass of all atoms in a polymer chain. PAM batches vary in size distribution, but average size determines its behavior:

- Smaller PAM molecules dissolve quickly, create thinner solutions, and work best for fast-spreading uses like paints, glues, or papermaking.

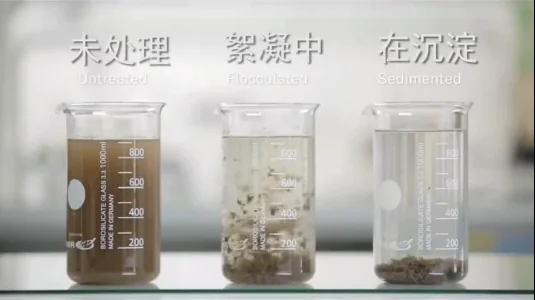

- Larger PAM molecules make thicker solutions and clump particles more effectively. Ideal for wastewater treatment, mining, or oil recovery where strong clumping is needed.

Choosing the Right PAM Size

Picking the correct molecule size boosts efficiency, cuts chemical use, and saves costs:

- Wastewater treatment: Large PAM forms dense clumps, speeds up sludge settling, and reduces drying costs.

- Papermaking: Medium-small PAM strengthens paper and evens out additives for better quality.

- Oil drilling: Extra-large PAM helps recover more oil during advanced drilling stages, lowering extraction costs.

Testing PAM Molecule Size

To confirm PAM quality, companies can use:

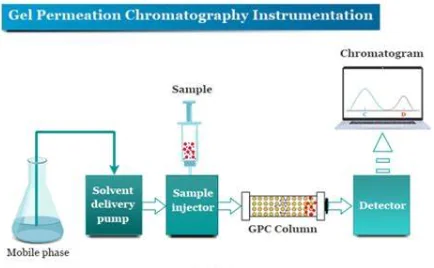

- Gel Permeation Chromatography (GPC): Measures exact molecule size ranges.

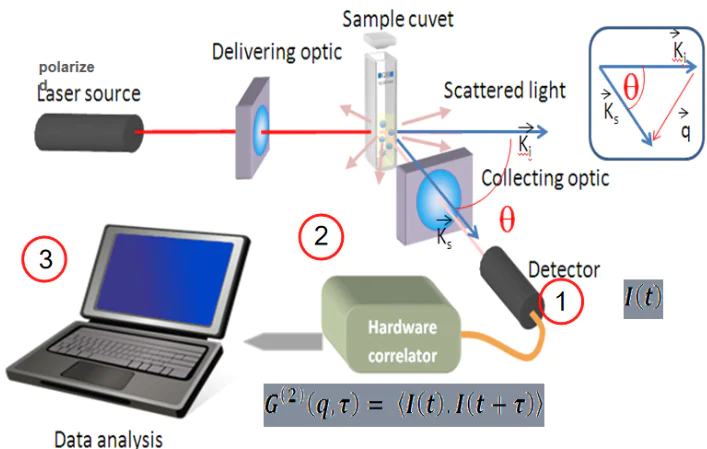

- Dynamic light scattering (DLS): Rapid analysis of the molecular weight range and particle distribution of PAM.

Optimize PAM selection to achieve cost reduction and efficiency increase

Matching PAM size to your needs ensures better results with less product. This cuts overall costs while maintaining performance—whether improving water treatment, product quality, or industrial processes.

Need cost-effective PAM solutions? Contact us for tailored advice to reduce costs and maximize efficiency!