In wastewater treatment, foam formation is a recurring headache for engineers and plant operators. This article focuses on two core areas:

- the working principle of defoamers

- and the common types used in wastewater systems.

Through technical insight and practical scenarios, we’ll help professionals select the right defoamer solution efficiently and economically.

🔬How Do Defoamers Work?

Rapid foam suppression and process stability assistance are the two main goals of defoamer application.

Foam may result from fluctuating influent quality, overloaded bioreactors, residual surfactants, or excessive aeration. Persistent foaming can lead to:

- Misreading of level sensors

- Tank overflows

- Equipment malfunction

- Process instability

Defoamers are chemical additives designed to quickly eliminate surface foam. Their mechanisms include:

- Reducing surface tension Most defoamers have extremely low surface tension, allowing them to penetrate the foam film, making it lose elasticity and collapse.

- Creating film instability Defoamers induce pressure imbalance or stretching on foam membranes, causing them to rupture.

- Fast spreading and coverage Effective defoamers disperse rapidly throughout the system and blanket foam-prone zones for efficient control.

⚠️ Note: Chemical defoamers are best suited for short-term foam suppression. Long-term foam control still relies on optimizing operational parameters and addressing root causes.

🧴Common Defoamer Types in Wastewater Treatment

Here are the five main types of defoamers commonly used in industrial and municipal wastewater settings:

1. Silicone-Based Defoamers

These are the most widely used. Typically white, viscous emulsions containing dimethyl silicone oil, hydrophobic silica, etc.

Pros:

- Ultra-low surface tension, rapid defoaming

- Effective in both water- and oil-based systems

- Affordable and easy to use

Cons:

- Poor high-temp stability

- Excessive dosing may clog membranes and foul downstream units

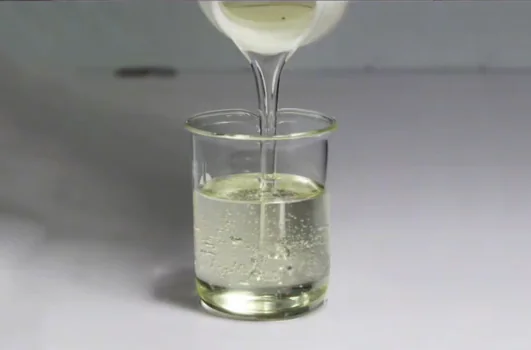

2. Polyether-Based / Polyether Ester Defoamers

Usually clear or light yellow liquids with excellent foam suppression performance.

Advantages:

- Strong anti-foaming ability

- Slower but more sustained effect

- Stable under high temp, acid/alkaline conditions

- Minimal impact on microbial communities

✅ Best choice for biological treatment systems requiring safe long-term control.

3. Silicone-Polyether Hybrids

Combines the advantages of silicone and polyether defoamers.

- Great temperature resistance and chemical compatibility

- Offers both fast defoaming and prolonged suppression

- Suitable for complex wastewater environments (e.g., with strong surfactant loads)

4. Mineral Oil-Based Defoamers

Less common in wastewater; more often used in industrial systems like inks, paints, or cutting fluids.

- Water-insoluble, disrupts foam films easily

- Potent and fast-acting

- Best for non-aqueous or heavy oil-based foams

5. High-Carbon Alcohol Defoamers

Niche but effective in handling stubborn foam systems.

- Strong hydrophobicity and good dispersibility

- High-temp and strong alkaline resistance

- Low residue, no gray spotting

📌 Ideal for paper mill effluent, fermentation liquids, or refractory foaming wastewater.

🎯Summary: Smart Selection + Systematic Control

Defoamers are essential support chemicals in wastewater treatment, especially for emergency foam control. However, true foam management should go beyond surface solutions.

💡 The key lies in selecting defoamers based on foam causes, system design, and operating conditions, while also fine-tuning the upstream processes.

📞 If you’re struggling with persistent foam issues or unsure which product to use, our technical team is ready to offer tailored recommendations and on-site support.