The biofilm process is a common and efficient technology in biological wastewater treatment systems.

It is widely used in contact oxidation tanks, biofilters, and integrated treatment equipment.

Recently, many clients have asked about difficulties in biofilm formation during system start-up.

This article focuses on two key questions:

- What is the biofilm process?

- What factors affect biofilm formation?

What Is the Biofilm Process?

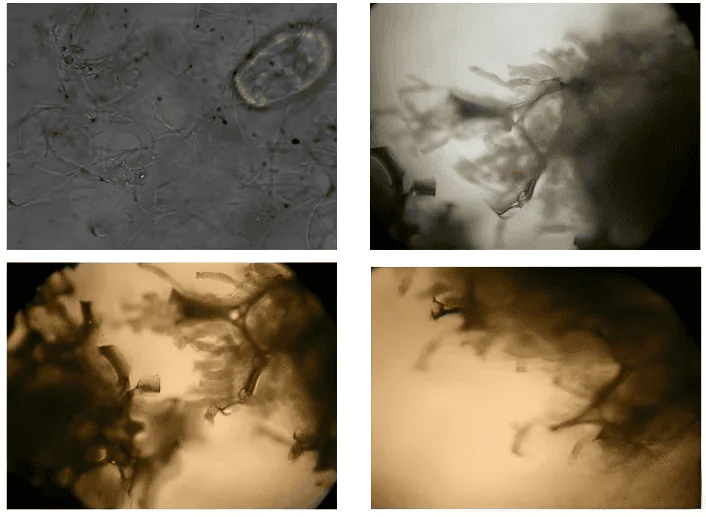

The biofilm process refers to microorganisms attaching to the surface of carriers (fillers) and forming a stable biological film.

Through microbial metabolism, organic pollutants in wastewater are gradually degraded.

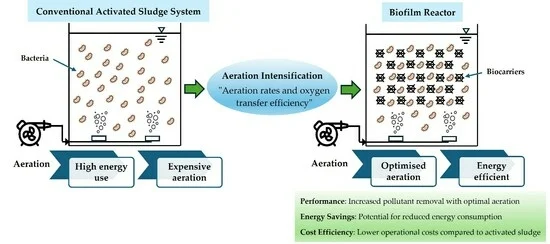

Compared with the traditional activated sludge process, the biofilm process offers clear advantages:

- High organic load capacity

- Strong resistance to shock loads

- Low sludge production

- More stable system operation

In anaerobic, anoxic, and aerobic tanks, adding carriers allows sludge–biofilm symbiosis, which further improves overall treatment efficiency.

Five Key Factors Affecting Biofilm Formation

The speed and quality of biofilm formation directly affect start-up time and system stability.

The following five factors play a critical role.

1. Temperature and pH

Microorganisms grow best under suitable environmental conditions.

- Optimal temperature: 20–30°C

- Suitable pH range: 6.5–8.0

Stable temperature and pH help microorganisms stay active, improving attachment and accelerating biofilm growth.

2. Type and Performance of Fillers

Common fillers include:

- Elastic carriers

- Combined carriers

- Suspended fillers

Their surface roughness, specific surface area, hydrophilicity, and electrical properties strongly affect microbial attachment.

In general, fillers with rough surfaces and large surface area support faster and stronger biofilm formation.

3. Sludge Concentration

Higher sludge concentration means more microorganisms are present in the system.

This increases contact opportunities between microbes and fillers, helping biofilm form more quickly.

However, sludge concentration should still be controlled to avoid operational problems.

4. Hydraulic Load

Excessive hydraulic load or high flow velocity can wash away weakly attached microorganisms.

Proper flow control provides a stable environment for biofilm growth and maturation.

5. Aeration Intensity

Over-aeration in the filler zone creates strong shear forces.

This prevents microorganisms from attaching and may damage newly formed biofilm.

Aeration should meet oxygen demand without disturbing biofilm attachment and stability.

Conclusion

Biofilm formation is a dynamic and complex process influenced by many factors.

Only when temperature, water quality, hydraulic conditions, filler performance, and microbial activity are well balanced can biofilm form quickly and remain stable.

If you experience slow start-up, poor biofilm formation, or unstable operation, professional technical support can help optimize your system and restore performance.