Anaerobic biological treatment is widely used for high-strength organic wastewater. It offers low energy consumption, low sludge production, and valuable energy recovery. With stricter environmental regulations, this technology is becoming more important worldwide.

This article answers two key questions:

- What is anaerobic biological treatment?

- What factors affect its treatment efficiency?

What Is Anaerobic Biological Treatment?

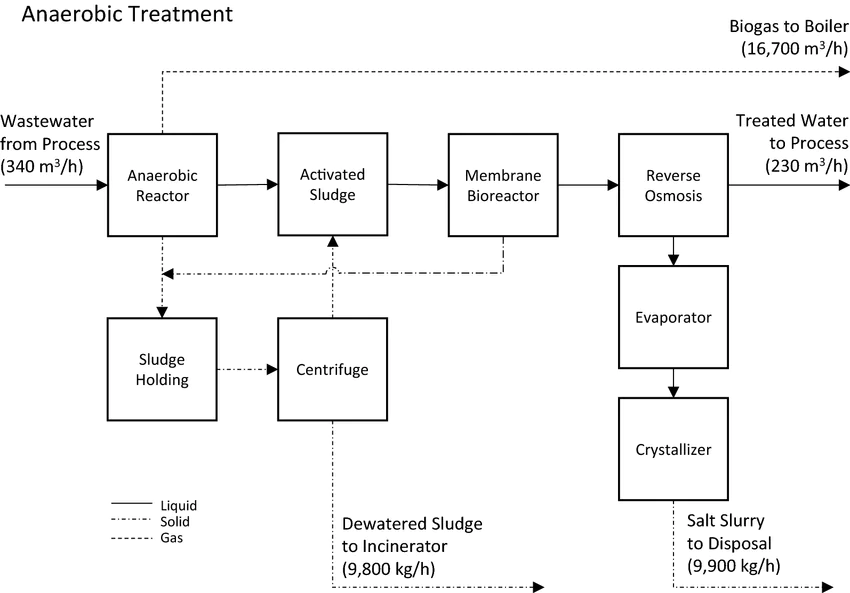

Anaerobic biological treatment works in an oxygen-free environment. Anaerobic and facultative bacteria break down organic pollutants and finally convert them into methane (CH₄) and carbon dioxide (CO₂).

The process includes four main stages, and each stage relies on different bacteria working together.

Four Key Stages of Anaerobic Treatment

1. Hydrolysis Stage

Large and hard-to-degrade organic matter is broken into smaller, soluble compounds that bacteria can absorb.

2. Acidogenesis Stage

Small organic compounds are further decomposed into volatile fatty acids (VFA).

3. Acetogenesis Stage

Acid-producing bacteria convert VFA into acetic acid and other simple compounds.

4. Methanogenesis Stage

Methanogenic bacteria convert acetic acid and formic acid into methane and carbon dioxide.

This stage enables biogas recovery and energy reuse.

Stable operation depends on proper coordination between these bacteria and suitable operating conditions.

Six Key Factors That Affect Anaerobic Treatment Efficiency

1. pH Control

Anaerobic systems are highly sensitive to pH.

- Ideal influent pH: 6.5–8.0

- Best pH for methane bacteria: 6.8–7.5

If pH drops too low, methane bacteria activity decreases and the reaction slows down.

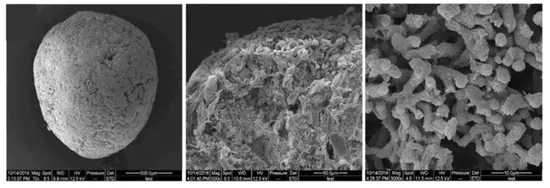

2. Suspended Solids (SS)

High SS content slows hydrolysis and acidification.

It may block gas release on granular sludge, leading to:

- Sludge swelling

- Lower sludge density

- Sludge wash-out

Proper pretreatment should reduce SS concentration and particle size.

3. Temperature

Temperature strongly affects microbial activity. For most mesophilic systems, the optimal temperature is around 35°C. Rapid temperature changes can reduce system stability and treatment efficiency.

4. Organic Load

Excessive organic load or high flow rates cause VFA accumulation. This inhibits methane bacteria growth and reduces COD removal efficiency. The influent load must match the system design capacity.

5. Toxic and Harmful Substances

Wastewater containing sulfides, heavy metals, disinfectants, or other toxic compounds can damage methane bacteria. In severe cases, the entire anaerobic system may fail. Pretreatment is essential to remove or reduce toxic substances.

6. Nutrient Ratio

Microorganisms need balanced nutrients for growth. The recommended C:N:P ratio is 100:5:1. Nutrient deficiency reduces microbial activity and weakens treatment performance.

Conclusion

Anaerobic biological treatment requires strict control of operating conditions.

To maintain a stable and efficient system, operators must manage:

- pH

- Temperature

- Organic load

- Suspended solids

- Toxic substances

- Nutrient ratio

If you experience problems such as low biogas production, sludge swelling, or poor system start-up, professional technical support can help restore stable operation.