Dyeing and textile wastewater is widely recognized as one of the most difficult industrial wastewaters to treat. Unlike ordinary high-COD wastewater, color itself becomes the primary pollutant, directly affecting visual discharge standards and public perception.

Poly Aluminum Chloride (PAC) is widely used in textile wastewater treatment, especially in the decolorization and primary clarification stage, due to its strong adsorption and flocculation capability.

Key Challenges of Dyeing Wastewater

Textile wastewater typically shows the following characteristics:

- Extremely high chromaticity caused by residual dyes

- Large molecular dye structures that are difficult to biodegrade

- High COD and fluctuating pH

- Presence of surfactants and auxiliaries

Biological treatment alone is often ineffective, making chemical coagulation a necessary pretreatment step.

Why PAC Is Effective for Color Removal

PAC hydrolyzes in water to form Al(OH)₃ polymeric colloids, which provide:

- Strong adsorption of dye molecules

- Effective charge neutralization

- Bridging between dye particles

Compared with traditional aluminum sulfate, PAC forms larger and denser flocs, leading to faster settling and better color removal.

Typical Treatment Process Using PAC

In most dyeing plants, PAC is applied as follows:

- pH adjustment to the optimal range

- PAC dosing (0.8–1.2‰) in rapid mixing

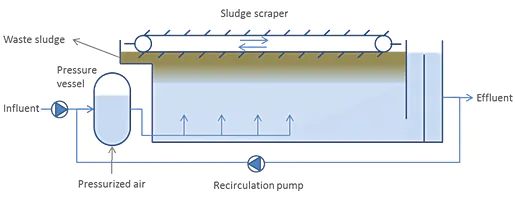

- Flocculation and air flotation or sedimentation

- Secondary biological treatment

This combination allows color removal rates of up to 90%.

Common Operational Considerations

- Overdosing PAC may increase sludge volume

- pH control is critical for stable color removal

- Jar testing is recommended for each dye batch

Conclusion

PAC plays a decisive role in textile wastewater decolorization. By removing color and reducing COD load at the pretreatment stage, PAC ensures stable downstream biological treatment and compliance with discharge standards.