Why PAM Selection Matters in Oilfield Operations

In drilling, completion, and cementing operations, fluid performance directly affects wellbore stability, formation protection, displacement efficiency, and overall well cost. Polyacrylamide (PAM) is widely used across these operations because it delivers viscosity control, filtration reduction, shale stabilization, and solids management without adding excessive solids to the system.

However, field problems such as unexpected gelation, poor cleanup, pumping issues, or formation damage are often traced back to incorrect PAM selection or application, not the polymer itself.

This guide is written for drilling engineers, completion supervisors, laboratory technicians, and procurement teams, providing field-proven guidance on how to select and apply PAM safely and effectively.

Why Polyacrylamide Is Widely Used in Oilfield Fluids

PAM polymers offer a unique combination of properties that make them suitable for oilfield use:

- High molecular weight for effective viscosity and flocculation control

- Adjustable charge (anionic, cationic, nonionic)

- Low solids contribution

- Compatibility with many water-based systems

When properly selected, PAM helps achieve target rheology and filtration performance while minimizing formation damage risk.

Core Functions of PAM in Drilling Fluids

In drilling applications, PAM is commonly used to fine-tune fluid behavior rather than to completely redesign the system.

Key Functional Roles

- Rheology modification

Enhances low-shear-rate viscosity for cuttings transport while maintaining pumpability at high shear. - Filtration control and bridging support

Reduces API and HPHT fluid loss by assisting pore bridging and filter cake formation. - Shale and fines stabilization

Binds dispersed fines and reduces clay mobility when used with appropriate salts or inhibitors. - Solids control enhancement

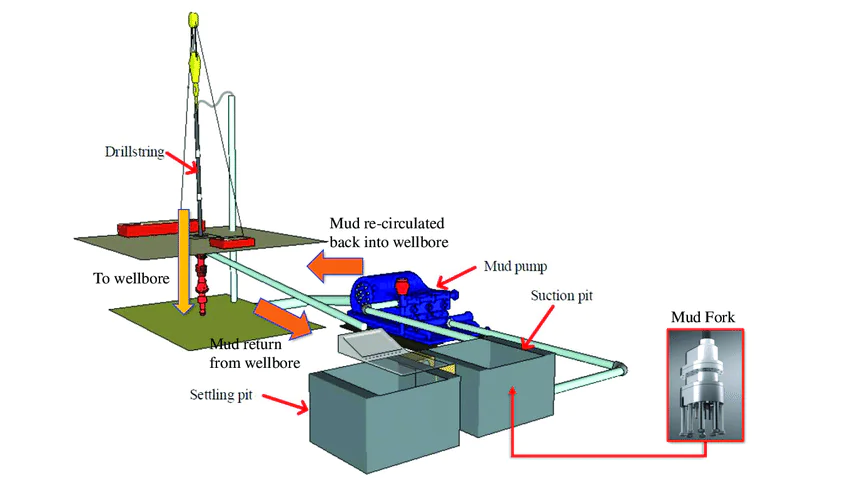

Acts as a flocculant to improve solids removal efficiency in desanders and desilters.

Procurement insight:

Different objectives require different PAM structures—no single grade fits all drilling conditions.

Selecting the Right PAM: What Procurement and Engineers Must Align On

Selecting PAM should be based on well conditions, not just product availability.

Key Selection Parameters

| Parameter | Why It Matters |

|---|---|

| Polymer charge | Controls interaction with clays and fines |

| Molecular weight | Affects viscosity, filtration, and floc size |

| Salinity tolerance | Prevents precipitation in brines |

| Thermal stability | Ensures performance at BHST |

| Physical form | Affects mixing and field handling |

Typical PAM Types and Uses

- Anionic PAM

Common for rheology adjustment and filtration control; sensitive to multivalent ions. - Cationic PAM

Effective for clay binding and shale stabilization in low-salinity systems. - Nonionic PAM

Preferred in high-salinity or mixed-brine environments due to better compatibility.

Laboratory Validation Before Field Use (Non-Negotiable)

Field success starts in the lab. Before deploying PAM in drilling fluids, conduct:

- Rheology profiling at target temperature and shear rates

- API and HPHT filtration tests

- Compatibility testing with brines and additives

- Thermal aging under expected downhole conditions

Skipping these steps often leads to overdosing, unstable rheology, or poor filtration control in the field.

Field Dosing and Application: Practical Guidance

Conservative Dosing Strategy

- Typical starting range: 0.05–2.0 kg/m³ (0.05–2.0 g/L)

- Always start at the low end and adjust gradually

- Allow sufficient mixing time before evaluation

Mixing Best Practices

- Add PAM slowly into an agitated system

- Avoid high shear during initial hydration

- Use dispersants for powdered grades if required

- Re-test rheology and filtration after 10–30 minutes

Improper hydration is one of the most common causes of PAM performance failure.

PAM in Completion Fluids: Focus on Cleanup and Formation Protection

In completion operations, PAM is primarily used to:

- Control fluid loss

- Suspend solids or proppant

- Condition fluids for perforating and stimulation

Completion-Specific Selection Guidance

- Prefer low-residue or lower-MW grades

- Use nonionic or tailored low-charge PAM in high-salinity brines

- Always run core-flow or formation-damage tests

Completion fluids demand performance with minimal residual damage, making polymer selection critical.

PAM in Cementing Fluids: Benefits and Cautions

In cementing, PAM can improve slurry placement by:

- Modifying slurry rheology

- Reducing early-stage fluid loss

- Improving displacement efficiency

Cementing-Specific Risks

- Interaction with cement dispersants or retarders

- Changes in thickening time

- Density or rheology instability

Mandatory tests include:

- Thickening time (API RP 10B-2)

- HPHT fluid-loss testing

- Compatibility with cement additives

Never assume PAM compatibility with cement systems without testing.

Common Field Problems and How to Fix Them

| Issue | Likely Cause | Practical Fix |

|---|---|---|

| Rapid gelation | Multivalent ion incompatibility | Switch to nonionic or low-charge PAM |

| Poor filtration control | Incorrect MW or underhydration | Verify grade and mixing procedure |

| Pumping/stringers | Overconcentrated solution | Improve dilution and filtration |

| Formation damage | Excess residue | Use lower-MW or cleanup-verified grade |

Environmental, Health, and Safety Considerations

- Select low residual acrylamide grades

- Follow MSDS handling guidelines

- Use PPE for powder handling

- Manage polymer-containing waste via solids separation

EHS compliance is not optional in modern oilfield operations.

Quick Reference: Conservative Starting Dosages

| Application | Typical Starting Dose |

|---|---|

| Drilling fluids | 0.05–2.0 kg/m³ |

| Completion fluids | 0.5–5 g/L |

| Cementing fluids | 0.1–1.0% BWOW |

Always confirm with lab testing before scaling up.

Conclusion: PAM Is Powerful Only When Properly Selected and Controlled

Polyacrylamide is a flexible, high-performance additive for drilling, completion, and cementing fluids—but only when grade, dosage, and handling are matched to well conditions and validated by laboratory testing.

For operators and procurement teams, the goal is not simply to buy PAM, but to control fluid performance, reduce operational risk, and protect the formation. Working with a supplier that understands both polymer chemistry and field realities is often the difference between consistent performance and recurring problems.