Why PAM Is Widely Used in Drilling Fluids

Modern drilling operations demand fluids that provide effective hole cleaning, stable rheology, and controlled filtration, while minimizing solids loading and formation damage. Polyacrylamide (PAM) has become a core additive because it delivers multiple functions with relatively low dosage.

From a procurement and engineering perspective, PAM offers cost efficiency, flexibility, and performance stability when properly selected and managed.

Core Functions of PAM in Drilling Fluids

1. Rheology Control for Hole Cleaning

PAM increases low-shear-rate viscosity (LSRV), allowing cuttings to remain suspended during circulation pauses, while maintaining pumpability at high shear rates.

This balance improves:

- Hole cleaning efficiency

- Reduced risk of cuttings bed formation

- Stable annular flow

2. Filtration and Fluid Loss Reduction

High-molecular-weight PAM forms polymer bridges across pore throats, reducing filtrate invasion into permeable formations.

Benefits include:

- Lower API and HPHT fluid loss

- Reduced differential sticking risk

- Improved wellbore stability

3. Shale and Clay Stabilization Support

When combined with KCl or other inhibitors, PAM:

- Binds reactive clay fines

- Limits dispersion and hydration

- Improves shale stability

This is especially valuable in water-sensitive formations.

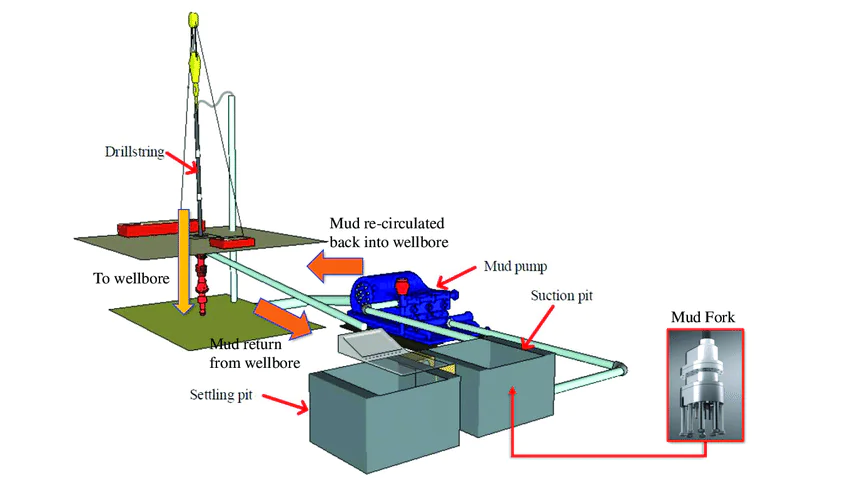

4. Solids Control and Flocculation Aid

PAM can be applied downstream of shale shakers as a polymer flocculant to enhance solids separation efficiency in desanders and centrifuges.

Selecting the Right PAM for Drilling Fluids

| Selection Factor | Practical Consideration |

|---|---|

| Molecular weight | Higher MW for filtration and flocculation |

| Charge type | Anionic most common in water-based muds |

| Salinity tolerance | Nonionic PAM for high-salinity systems |

| Thermal stability | Match to bottomhole temperature |

⚠️ Over-selecting molecular weight can cause excessive viscosity and pumping issues.

Laboratory Validation Before Field Use

Recommended tests:

- Rheology profiles (LSRV, YP, PV)

- API and HPHT filtration

- Brine compatibility

- Thermal aging under shear

Field Dosage and Mixing Guidelines

Typical dosage range:

0.05–2.0 kg/m³ (confirmed by lab testing)

Best practices:

- Add PAM slowly into active pit

- Ensure sufficient hydration time

- Avoid overdosing to prevent gelation

- Monitor rheology after each adjustment

Common Field Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Rapid viscosity rise | Overdosing | Reduce concentration |

| Poor filtration control | Low MW polymer | Upgrade grade |

| Polymer fish-eyes | Poor dispersion | Improve mixing |

| Clay dispersion | Wrong charge | Adjust polymer type |

Conclusion

Polyacrylamide (PAM) is a multifunctional additive that enhances drilling fluid performance while minimizing solids content. Proper selection, conservative dosing, and routine monitoring are essential to maximize benefits and avoid operational risks.