What Is Polyaluminium Chloride (PAC)?

Polyaluminium Chloride (PAC) is an inorganic polymer coagulant widely used in drinking water treatment, municipal wastewater treatment, and industrial wastewater treatment. It is produced by partially neutralizing aluminum chloride with hydroxide, resulting in a pre-hydrolyzed aluminum salt with strong coagulation ability.

Compared with traditional coagulants such as aluminium sulphate (alum), PAC contains polymeric aluminum species that are already partially hydrolyzed. This allows PAC to react faster with impurities in water, form stronger flocs, and work effectively over a wider pH and temperature range.

Why Polyaluminium Chloride Is Used in Water Treatment

Water sources usually contain suspended solids, colloids, organic matter, heavy metals, and microorganisms. Most of these impurities carry a negative surface charge, making them stable in water and difficult to settle naturally.

PAC is used because it can:

- Neutralize negative charges on particles

- Form dense, fast-settling flocs

- Reduce chemical consumption and sludge volume

- Improve treated water quality and process stability

In modern water treatment plants, PAC has gradually replaced alum and ferric salts in many applications due to its higher efficiency and lower operational cost.

How Does Polyaluminium Chloride Work?

Coagulation and Flocculation Mechanism

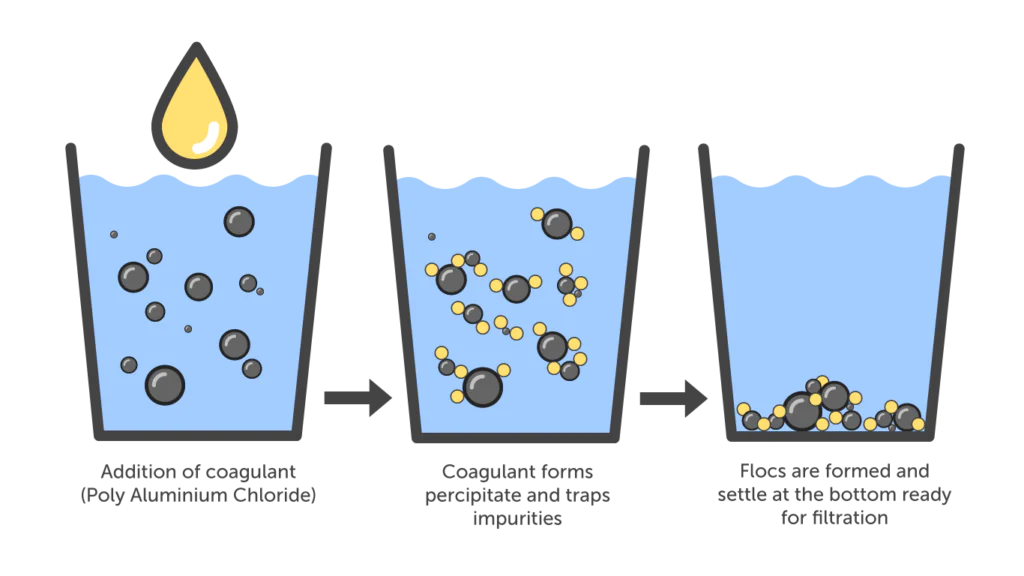

PAC is usually dosed at the coagulation stage, which is the first chemical step in water treatment. Its working mechanism includes:

1. Charge Neutralization

PAC releases highly charged aluminum polymer ions that neutralize the negative charge on suspended particles. Once the electrostatic repulsion is reduced, particles can approach each other.

2. Adsorption and Bridging

The polymerized aluminum species adsorb onto multiple particles at the same time, forming bridges that link small particles into larger flocs.

3. Sweep Flocculation

At appropriate dosage, PAC forms aluminum hydroxide precipitates that “sweep” fine particles out of the water as they settle.

The formed flocs are then removed through sedimentation, dissolved air flotation (DAF), or filtration.

Key Features and Advantages of Polyaluminium Chloride

PAC has several technical advantages that make it suitable for both municipal and industrial systems.

Main Advantages of PAC

- Fast floc formation and settling

- Lower dosage compared with alum

- Less sludge production

- Wide pH working range (pH 5–9)

- Effective at low water temperature

- Lower residual aluminum in treated water

- Easy handling and stable performance

Because of these features, PAC is widely used in high-load and variable water quality systems, where process stability is critical.

PAC vs Traditional Coagulants (Alum & Ferric Salts)

| Item | PAC | Aluminium Sulphate (Alum) | Ferric Salts |

|---|---|---|---|

| Effective dosage | Low | High | Medium |

| Sludge volume | Low | High | High |

| pH adaptability | Wide | Narrow | Medium |

| Low-temperature performance | Good | Poor | Medium |

| Residual metal risk | Low Al | Higher Al | Fe color risk |

From an operational perspective, PAC provides better cost-performance, especially in large-scale or continuously operating plants.

Typical Applications of Polyaluminium Chloride

PAC is suitable for a wide range of water treatment scenarios.

1. Drinking Water Treatment

- Turbidity removal

- Color and organic matter reduction

- Algae and microorganism control

2. Municipal Wastewater Treatment

- Primary clarification

- Phosphorus removal

- Sludge conditioning

3. Industrial Wastewater Treatment

PAC is widely used in:

- Paper mill wastewater

- Textile and dyeing wastewater

- Food and beverage wastewater

- Oil refinery and petrochemical wastewater

- Pharmaceutical wastewater

PAC Dosage Guidelines and Influencing Factors

Typical PAC Dosage Range

- Drinking water: 5–30 mg/L

- Municipal wastewater: 20–100 mg/L

- Industrial wastewater: 50–300 mg/L (depending on pollution load)

⚠️ These values are starting points only. Actual dosage must be determined by jar tests.

Factors Affecting PAC Dosage

- Raw water turbidity and COD

- pH and alkalinity

- Water temperature

- Mixing conditions

- Presence of organic matter or oil

Combining PAC with PAM for Better Performance

In many treatment systems, PAC is used together with Polyacrylamide (PAM) to improve flocculation efficiency.

Why Use PAC + PAM?

- PAC handles charge neutralization

- PAM provides polymer bridging

- Larger and stronger flocs

- Faster settling or flotation

- Better sludge dewatering

Typical Practice

- PAC is dosed first at the coagulation stage

- PAM is added at low dosage during flocculation

PAM flocculant for water treatment

Common Problems When Using PAC and Solutions

Problem 1: Small or Loose Flocs

Solution: Increase PAC dosage slightly or adjust pH to optimal range.

Problem 2: High Residual Turbidity

Solution: Improve mixing efficiency and check coagulant injection point.

Problem 3: Excessive Sludge

Solution: Reduce overdose and optimize PAC–PAM combination.

Problem 4: Residual Aluminum Concern

Solution: Use high-basicity PAC and ensure correct dosage control.

Environmental and Safety Considerations

PAC is considered a safe and environmentally friendly coagulant when used correctly.

- Low toxicity

- No secondary pollution

- Lower sludge disposal cost

- Suitable for potable water systems

Operators should still follow MSDS guidelines and ensure proper storage and handling.

Conclusion

Polyaluminium Chloride (PAC) is one of the most effective and widely used coagulants in modern water treatment systems. Its strong coagulation ability, wide adaptability, and economic advantages make it an ideal choice for drinking water, municipal wastewater, and industrial effluent treatment.

When combined with proper dosage control, jar testing, and PAM flocculants, PAC can significantly improve treatment efficiency, reduce operating costs, and ensure stable water quality compliance.