Polyacrylamide (PAM) is one of the most widely used flocculants in wastewater treatment, sludge dewatering, and industrial solid–liquid separation. Although PAM is highly efficient, improper preparation or dosing can significantly reduce its performance and even increase operating costs.

This article summarizes key precautions for using PAM in real applications, helping operators and procurement teams avoid common mistakes and achieve stable treatment results.

1. Dissolution Process of PAM

Solid polyacrylamide must not be added directly into wastewater. It must first be dissolved into an aqueous solution before use.

Key Dissolution Guidelines

- PAM powder should be slowly sprinkled into clean water

- Continuous and gentle stirring is required

- Avoid rapid dumping, which causes fish-eyes or clumping

- Ensure sufficient hydration time before dosing

Improper dissolution leads to incomplete polymer chain expansion, reducing flocculation efficiency.

2. Concentration Control of PAM Solution

The recommended working solution concentration for PAM is usually around 0.1%.

Why Concentration Matters

- Too high concentration

- Difficult to disperse evenly

- Increased chemical waste

- Higher risk of overdosing

- Too low concentration

- Weak flocculation effect

- Inconsistent treatment results

Maintaining proper solution strength ensures stable dosing and efficient polymer utilization.

3. Matching PAM Type with Sludge Properties

Selecting the correct PAM grade is critical. Different sludge types require different cationic degree and molecular structure.

Selection Considerations

- Cationic PAM is mainly used for organic sludge dewatering

- Sludge pH affects polymer adsorption behavior

- Strongly acidic or alkaline sludge requires specialized grades

- Sludge source and composition should always be evaluated first

Incorrect matching can result in:

- Poor floc formation

- High cake moisture

- Increased polymer consumption

4. Regulation of Flocculation Performance

The molecular weight of PAM directly affects floc size and structure.

Practical Adjustment Principles

- Larger molecular weight → larger flocs

- Excessively tight flocs reduce drainage efficiency

- Over-flocculation can increase cake resistance

The goal is to form flocs that:

- Drain water efficiently

- Maintain sufficient mechanical strength

- Do not compact excessively during dewatering

Proper molecular weight selection helps achieve optimal sludge cake dryness.

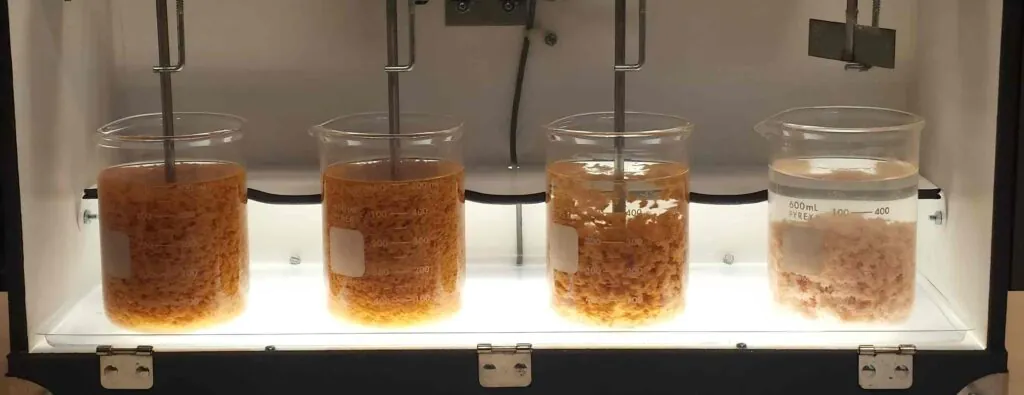

5. Flocculant Screening Before Full-Scale Use

Before large-scale application, jar tests or small-scale trials are essential.

Benefits of Pre-Testing

- Identify optimal PAM type

- Determine minimum effective dosage

- Reduce chemical costs

- Avoid operational instability

Laboratory screening ensures cost-effective and reliable long-term operation.

6. Using PAM Together with Other Chemicals (e.g. PAC)

In many treatment systems, PAM is used together with inorganic coagulants such as polyaluminum chloride (PAC).

Important Combination Rules

- PAM and PAC must be dissolved separately

- Add PAC first, then PAM

- Strictly control:

- Dosing sequence

- Dosing ratio

- Addition speed

Improper mixing or incorrect order may lead to:

- Reduced flocculation efficiency

- Chemical interference

- Increased sludge production

Conclusion

Polyacrylamide is a highly effective flocculant, but its performance depends heavily on correct handling and application. By paying close attention to:

- Proper dissolution

- Solution concentration

- Sludge matching

- Molecular weight control

- Pre-application testing

- Correct combination with PAC

operators can achieve stable treatment performance, lower operating costs, and better sludge dewatering results.