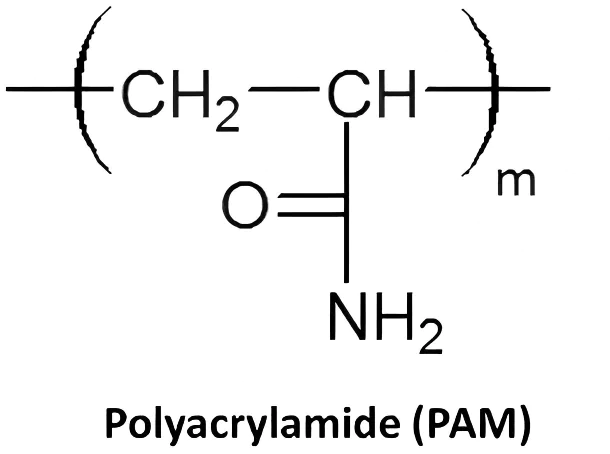

Polyacrylamide (PAM) is a high-performance water-soluble polymer produced by the polymerization of acrylamide monomers. It has a linear molecular structure, appears as a white or colorless solid, and is odorless and non-toxic when properly manufactured and applied.

Thanks to its adjustable molecular weight and charge type, polyacrylamide has become an essential functional chemical across multiple industries, especially where solid–liquid separation, viscosity control, and particle aggregation are required.

1. Polyacrylamide in Oilfield Applications

The oil and gas industry is one of the largest consumers of polyacrylamide. PAM is mainly used to improve operational efficiency and reduce formation damage during oil extraction.

Key Oilfield Uses

① Drilling Fluids

Polyacrylamide is used to:

- Adjust drilling fluid rheology

- Improve cuttings suspension

- Reduce fluid loss

- Stabilize wellbore walls

② Oil Displacement (Enhanced Oil Recovery, EOR)

High-molecular-weight PAM increases water viscosity, improving the sweep efficiency of injected water and enhancing crude oil recovery rates.

③ Fracturing Fluids

PAM helps control fluid viscosity and proppant transport, ensuring efficient fracture propagation while minimizing residue.

2. Polyacrylamide in Water Treatment

Water treatment is the most widely known application of polyacrylamide.

Major Functions in Water Treatment

- Flocculation and sedimentation

- Sludge dewatering

- Solid–liquid separation

- Improvement of effluent clarity

PAM is extensively used in:

- Municipal wastewater treatment plants

- Industrial wastewater systems

- Sludge dewatering units (belt press, centrifuge, filter press)

Cationic, anionic, and nonionic PAM grades are selected based on water quality and sludge characteristics.

3. Polyacrylamide in the Papermaking Industry

In papermaking, polyacrylamide functions as a process aid rather than a simple flocculant.

Main Roles of PAM in Papermaking

- Retention aid for fine fibers and fillers

- Drainage and filtration aid

- Fiber dispersant

- Dry strength enhancement

PAM improves:

- Paper formation uniformity

- Raw material utilization

- Production efficiency

- Finished paper strength and quality

4. Polyacrylamide in Mineral Processing

Polyacrylamide is widely applied in mining and mineral beneficiation operations.

How PAM Works in Mineral Processing

- Promotes rapid settling of mineral particles

- Enhances solid–liquid separation

- Improves thickener and clarifier efficiency

- Reduces tailings loss

By accelerating sedimentation, PAM helps:

- Increase production capacity

- Lower water consumption

- Reduce operating and disposal costs

5. Other Industrial Applications of Polyacrylamide

Beyond the four major industries, polyacrylamide is also widely used in:

- Construction materials (grouting, soil stabilization)

- Textile industry (sizing and wastewater treatment)

- Alcohol and fermentation industries

- Monosodium glutamate (MSG) production

- Sugar processing

In these sectors, PAM improves process stability, separation efficiency, and water reuse performance.

Conclusion

Polyacrylamide is a versatile and indispensable polymer across modern industries. Its ability to control viscosity, promote flocculation, and enhance separation efficiency makes it a key chemical in:

- Oilfield operations

- Water and sludge treatment

- Papermaking processes

- Mineral beneficiation

By selecting the correct PAM type and applying it properly, industries can achieve higher efficiency, lower costs, and more sustainable operations.