There are many types of defoamers, and they are widely used in industrial processes such as coatings, water treatment, chemicals, and construction. Defoamers work through two main mechanisms: foam suppression and foam breaking.

When a defoamer is added to a system, its molecules distribute randomly on the liquid surface. By inhibiting the formation of an elastic liquid film, the defoamer prevents foam from forming at the source.

Foam Suppression and Foam Breaking Mechanism

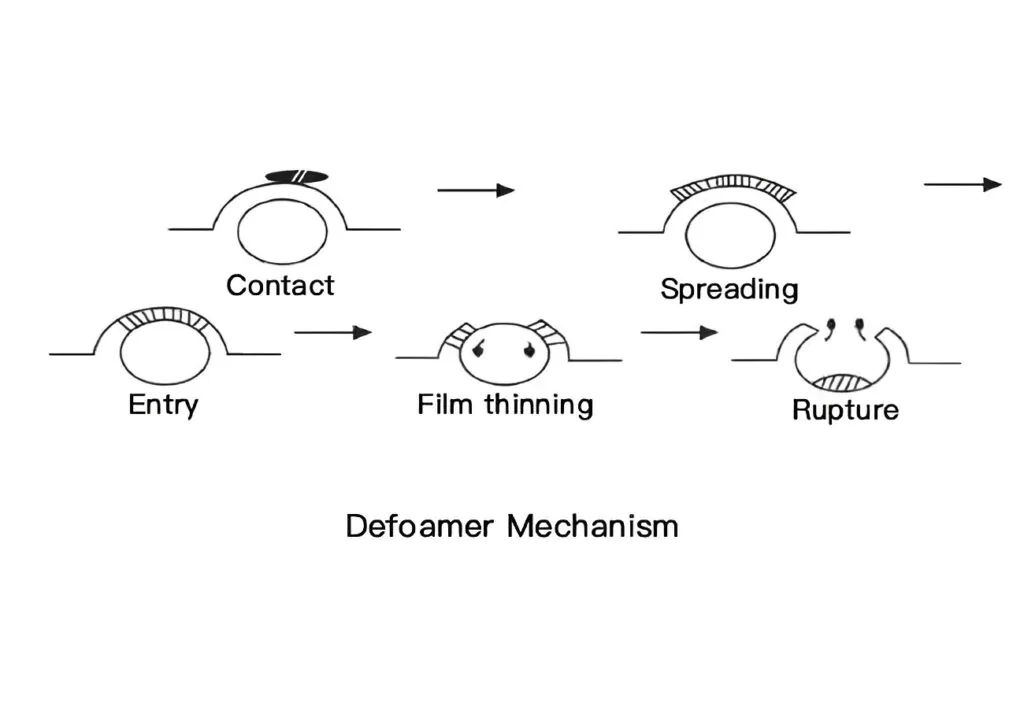

When a large amount of foam has already formed, the defoamer acts quickly.

Defoamer molecules spread rapidly across the foam surface and form a very thin double-layer film. These molecules continue to diffuse, penetrate, and invade the foam film layer by layer. As a result, the original foam film wall is gradually replaced.

Because defoamers have low surface tension, they naturally flow toward areas with higher surface tension where foam is present. This causes the foam film to thin rapidly. The surrounding high-tension liquid pulls unevenly on the foam film, creating stress imbalance and leading to foam collapse.

Defoamer particles that are insoluble in the system re-enter the surface of new foam films, repeating the process until the foam is fully eliminated.

How to Choose the Correct Antifoam

In coating production and construction, bubbles are almost unavoidable. Foam formation can disrupt production efficiency and cause surface defects in the finished coating film. Selecting the right defoamer ensures smooth processing and high-quality results.

The main task of a defoamer is to:

- Destroy the liquid film on bubble surfaces

- Prevent foam formation

- Promote rapid foam collapse

Defoamers are mainly effective against large bubbles. Microfoam often requires a combination of defoaming and degassing methods.

Key Features of Defoamers

A typical defoamer has the following characteristics:

- Insoluble in the system medium

- Disperses as fine microdroplets

- Effectiveness depends on droplet size

The most effective defoamer droplet diameter is close to the thickness of the foam wall. This allows efficient penetration and spreading within the foam film.

Defoamer Composition

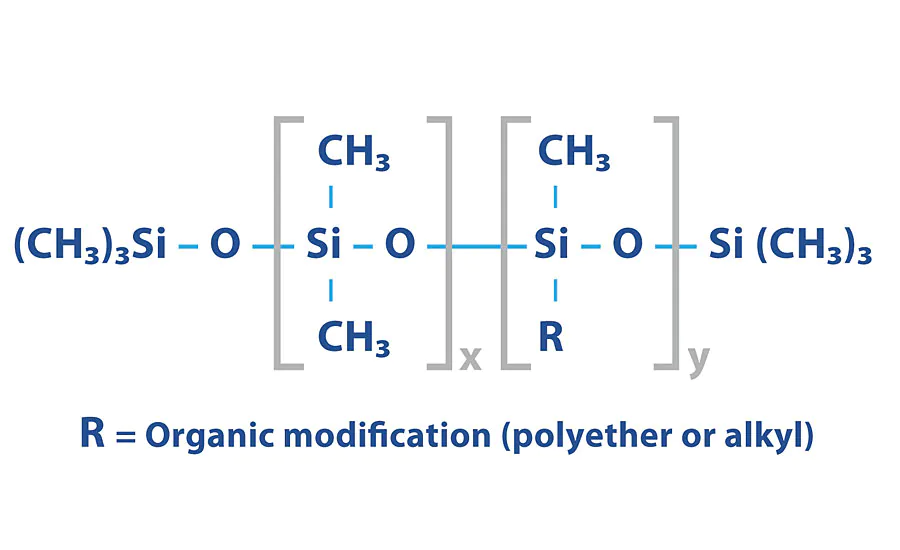

Defoamers used in water-based architectural coatings are generally divided into silicone-based and non-silicone-based types.

A conventional defoamer usually contains the following components:

Active Substance

This is the main foam-breaking agent with low surface tension. Typical examples include animal and vegetable oils, hydrophobic silica, and higher alcohols.

Diffusion Agent

This component acts as a wetting emulsifier, helping defoamer microdroplets spread across and contact the foam film. Common examples include nonylphenol polyoxyethylene ether and soap salts.

Carrier

The carrier helps the active substance disperse evenly into the foaming system. It improves compatibility, lowers surface tension, suppresses foam effectively, and helps reduce overall cost.

Conditions Required for Effective Defoaming

Two key physical conditions must be met for successful defoaming:

Penetration Factor

E = γ₁ + γ₁₂ − γ₃ > 0

This ensures the defoamer can penetrate the foam wall.

Spreading Factor

S = γ₁ − γ₁₂ − γ₃ > 0

This ensures defoamer droplets can spread and diffuse effectively in the foam medium. Only when both conditions are satisfied can the defoamer perform efficiently.

Article Summary

Defoamers play a critical role in controlling foam in industrial systems. By reducing surface tension, penetrating foam films, and disrupting film stability, defoamers effectively suppress and break foam. Choosing the correct antifoam depends on application conditions, foam type, and system compatibility. Proper selection ensures stable production, improved product quality, and reduced operational issues.