Fluoride is a naturally occurring mineral commonly present in groundwater and some drinking water sources. According to the World Health Organization (WHO), the recommended maximum fluoride concentration in drinking water is 1.5 ppm. Long-term exposure to excessive fluoride may lead to dental fluorosis and skeletal fluorosis, creating a clear need for effective fluoride control in water treatment systems.

In practical projects, fluoride removal is not only a compliance issue but also a long-term operational challenge. The selected treatment method must be stable, cost-effective, and suitable for continuous operation. Among commonly used water treatment chemicals, polyaluminium chloride (PAC) has proven to be a reliable option in many municipal and industrial applications.

Why Polyaluminium Chloride Is Commonly Used for Fluoride Removal

Polyaluminium chloride is an inorganic polymer coagulant produced by the controlled reaction of aluminum hydroxide and hydrochloric acid. Compared with conventional aluminum salts, PAC has a higher degree of polymerization and stronger charge density, which allows it to interact more effectively with dissolved contaminants.

In fluoride removal processes, these properties result in faster reaction speed, stronger adsorption capacity, and more stable floc formation. From an operational perspective, PAC is easier to control and less sensitive to raw water fluctuations, which is an important consideration for long-term plant operation.

Fluoride Removal Mechanism of PAC

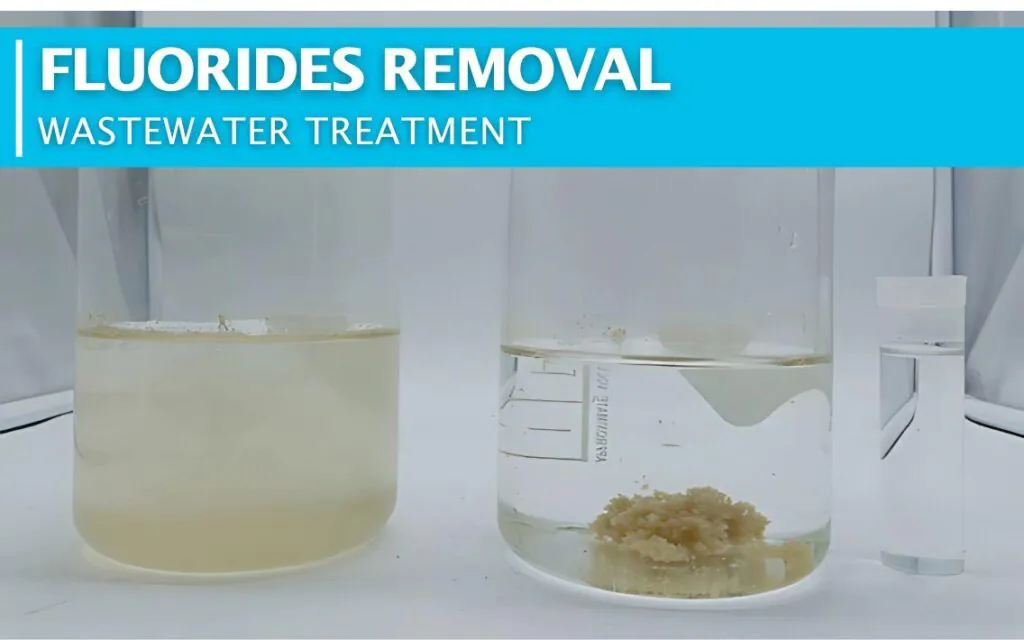

After PAC is added to water, it undergoes hydrolysis and releases positively charged aluminum species. These aluminum ions attract negatively charged fluoride ions through electrostatic forces, initiating adsorption. As the reaction progresses, PAC binds fluoride ions to form stable aluminum–fluoride complexes.

These complexes further transform into insoluble aluminum fluoride precipitates. At the same time, polymerized aluminum hydroxide flocs grow larger and capture fluoride-containing particles, allowing them to settle out of the water. This combined adsorption and precipitation mechanism effectively reduces free fluoride concentration and improves treatment stability under continuous operation.

Performance Advantages Observed in Practical Applications

One of the key reasons PAC is selected for defluoridation projects is its high removal efficiency. Under properly controlled conditions, fluoride removal rates above 90% are commonly achieved. Compared with traditional aluminum salts, PAC can improve defluoridation efficiency by approximately 30% at the same dosage, which directly reduces chemical consumption.

From a cost perspective, PAC-based treatment does not require complex equipment or high-pressure systems. In many engineering projects, overall treatment costs are reduced by more than 40% compared with membrane-based technologies. In addition, PAC performs effectively across a wide pH range of 5.0 to 9.0, with optimal performance typically observed at pH 6.5–7.5. At the same time, turbidity reduction and low sludge production further improve overall operational efficiency.

Key Design and Operation Considerations

In real-world applications, fluoride removal performance depends on several parameters, including raw water fluoride concentration, PAC dosage, and pH conditions. Simply increasing dosage does not always improve results and may lead to unnecessary chemical consumption or increased residual aluminum.

For this reason, jar testing or pilot testing is strongly recommended before full-scale application. This step helps determine the optimal PAC grade and dosage for specific water conditions, ensuring stable compliance while controlling operating costs.

Typical Application Scenarios

PAC is widely used in municipal drinking water treatment to ensure fluoride concentrations meet regulatory standards. Its stable performance and ease of control make it suitable for continuous treatment systems.

In industrial wastewater treatment, PAC is applied to fluoride-containing effluents from glass manufacturing, semiconductor processing, and fertilizer production. It is also used in groundwater remediation projects where natural fluoride contamination affects water quality. In agricultural water management, PAC helps remove fluoride from irrigation water, reducing long-term risks to soil and crops.

Why Product Quality and Technical Support Matter

Although PAC is widely available on the market, actual treatment performance can vary significantly between suppliers. Differences in basicity, polymerization degree, and impurity control directly affect fluoride removal efficiency and operational stability.

A reliable supplier should provide not only consistent product quality but also technical guidance based on real water conditions. This support is often the key factor in achieving stable long-term fluoride control rather than short-term test results.

PAC Supply and Technical Support

We provide polyaluminium chloride specifically formulated for fluoride removal in drinking water and industrial treatment systems. Our team supports customers with product selection, dosage optimization, and application guidance based on actual project conditions.

Free samples are available for testing, allowing you to evaluate performance before full-scale use. If you are planning a fluoride removal project or experiencing unstable treatment results, you are welcome to contact us to discuss your water conditions and treatment goals. We focus on practical solutions that work in real operating environments.