In modern industry, water quality, solid separation, and environmental compliance are critical. Polyaluminium chloride (PAC) coagulant has become a core chemical in many sectors because of its strong coagulation ability, fast floc formation, and wide pH adaptability. Beyond municipal water treatment, PAC supports production efficiency and pollution control in multiple industrial fields.

1. Water Treatment Industry

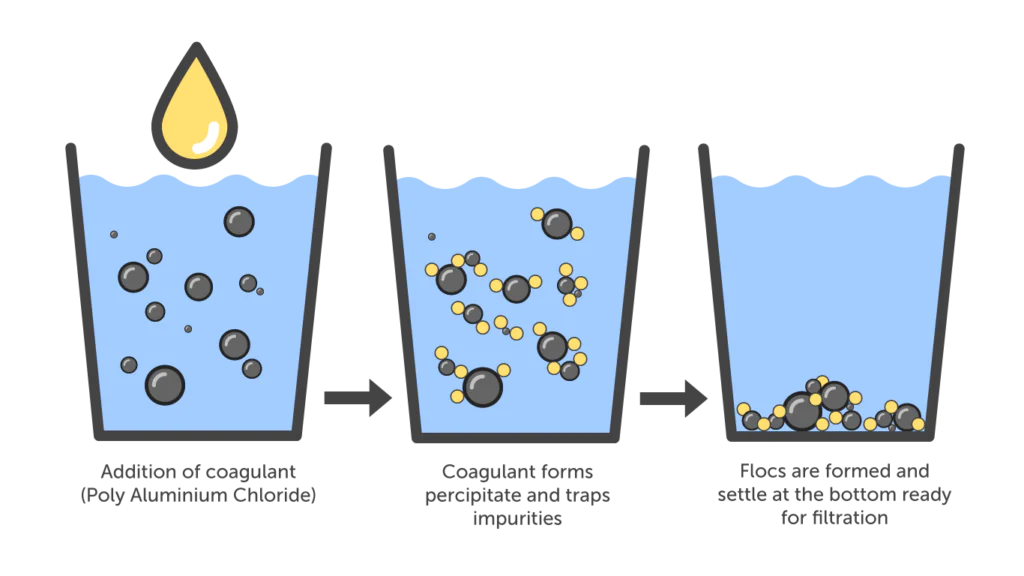

Water treatment is the largest application area for PAC. Raw water often contains suspended solids, colloids, organic matter, and microorganisms that are difficult to remove naturally. These particles usually carry negative charges, which keep them stable in water.

When PAC is added, it produces positively charged hydrolyzed aluminum species. These neutralize particle charges and form large, dense flocs. The flocs settle quickly, making solid-liquid separation much more efficient. PAC is widely used in drinking water plants, industrial water systems, and municipal wastewater treatment facilities. Its fast reaction speed and low sludge volume make it a preferred alternative to traditional coagulants in many projects.

2. Paper-Making Industry

In paper mills, PAC plays an important role in improving product quality and reducing material loss. Paper contains fillers such as calcium carbonate and clay to enhance brightness and smoothness. PAC helps bind these fine particles to fibers, increasing filler retention and reducing waste discharge.

PAC also improves sizing efficiency. Sizing controls how paper absorbs ink and liquids. By helping sizing agents attach to fibers more effectively, PAC supports better print quality and more stable production. This leads to lower chemical consumption and higher machine efficiency.

3. Mining Industry

Mining operations produce large volumes of wastewater containing fine mineral particles and heavy metals. These particles are extremely slow to settle without chemical assistance. PAC is used to accelerate sedimentation and improve water clarity in tailings ponds and mineral processing plants.

By forming heavier flocs, PAC helps separate solids from water more quickly. This allows treated water to be reused in the production process, reducing fresh water consumption. It also helps mining companies meet environmental discharge standards and lower the risk of regulatory penalties.

4. Textile Industry

Textile dyeing wastewater contains high levels of color, suspended solids, and organic pollutants. These contaminants are difficult to remove using biological treatment alone. PAC is commonly used as a pretreatment coagulant to remove dye particles and reduce turbidity.

After PAC dosing, dyes and colloidal particles form flocs and can be removed through sedimentation or flotation. This improves the performance of downstream treatment systems and helps factories meet discharge regulations. In many textile plants, PAC also supports water reuse systems by improving treated water clarity.

5. Food Processing Industry

Food processing requires large amounts of clean water for washing, rinsing, and production. PAC is sometimes used in production water pretreatment and internal wastewater treatment systems. It helps remove suspended solids and part of the organic load before filtration or biological treatment.

Because food safety standards are strict, PAC used in this sector must meet high purity requirements and be carefully dosed. When properly applied, PAC helps improve water quality while supporting safe and efficient food production operations.

Why So Many Industries Choose PAC

PAC is widely used across industries because it offers several practical advantages. It works in a broad pH range, forms flocs quickly, and produces less sludge compared with some traditional aluminum salts. It also adapts well to different water qualities, from low turbidity surface water to high-load industrial wastewater.

These features make PAC a reliable and cost-effective solution for solid-liquid separation in demanding industrial environments.

Conclusion: PAC Is More Than a Water Treatment Chemical

Polyaluminium chloride is no longer limited to municipal water plants. It has become a key chemical in paper production, mining wastewater control, textile effluent treatment, and even certain food processing applications. Its ability to improve clarification, reduce pollutants, and support water reuse makes it essential for modern industry.

If you are selecting a PAC grade for your specific industry or wastewater type, our technical team can help you choose the right specification and dosing strategy. Contact us for product details, samples, and application support.