In modern paper mills, especially those operating high-speed paper machines, dispersion stability directly determines sheet formation quality, filler distribution, energy consumption, and runnability.

When dispersion problems occur—such as fiber flocculation, uneven formation, or filler agglomeration—the issue is often traced back not to equipment, but to improper dispersant selection or control.

Dispersant PAM (Polyacrylamide) emulsions are widely used for this purpose. However, not all PAM dispersants perform the same, and procurement decisions based solely on price or generic specifications often lead to unstable production and increased operating costs.

This guide helps paper mill buyers, wet-end engineers, and technical managers understand how to select dispersant PAM emulsions that truly match their process conditions.

What Dispersant PAM Really Does in Paper Manufacturing

Dispersant PAMs are typically anionic or nonionic water-soluble polymers designed to:

- Maintain stable fiber dispersion

- Prevent filler and pigment agglomeration

- Reduce slurry viscosity

- Improve formation uniformity

From a purchasing perspective, the value of dispersant PAM is not only in dispersion itself, but in its ability to stabilize the entire wet-end chemistry system.

When correctly selected, dispersant PAM reduces fluctuations caused by:

- Raw material variability

- High shear forces

- Interactions with retention aids and sizing agents

Understanding the Flocculation and Dispersion Mechanism (Buyer-Level View)

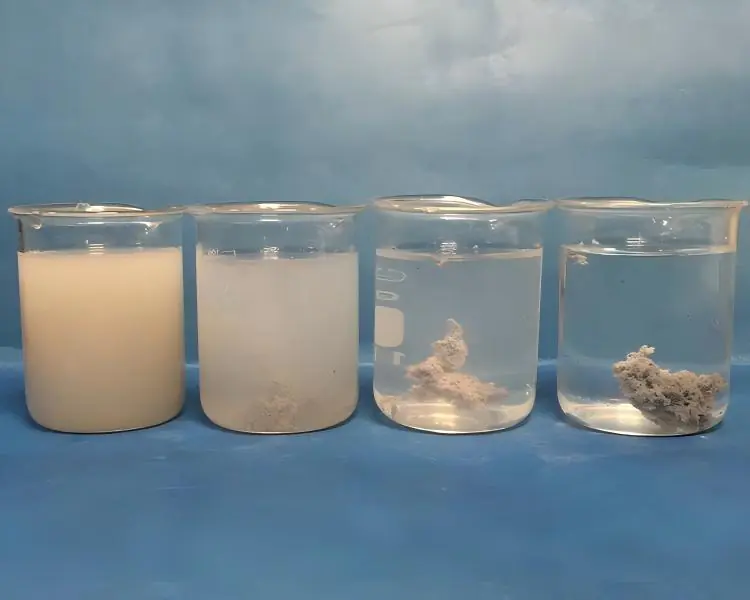

Paper fibers and fillers naturally carry negative surface charges. Under certain conditions—such as high ionic strength or improper chemical sequencing—these particles tend to re-flocculate.

Dispersant PAM emulsions work through controlled electrostatic repulsion and steric stabilization, preventing uncontrolled aggregation.

Practical Mechanisms That Matter to Buyers

- Electrostatic stabilization

Increases absolute zeta potential, keeping fibers separated even under turbulent flow. - Steric hindrance

Long polymer chains create physical barriers that prevent particle reattachment. - Filler compatibility

Prevents calcium carbonate and kaolin from forming hard aggregates that damage formation quality. - Rheology control

Improves pulp flow behavior, reducing refining and pumping energy demand.

For procurement teams, these mechanisms translate into more consistent quality and fewer operational complaints.

Where Procurement Often Goes Wrong

Mistake 1: Treating All Dispersant PAMs as Interchangeable

Different PAM emulsions vary significantly in:

- Molecular weight

- Charge density

- Emulsion stability

- Compatibility with other wet-end additives

Switching suppliers without retesting often leads to:

- Formation streaks

- Filler loss

- Drainage instability

Mistake 2: Ignoring Compatibility With Existing Wet-End Chemistry

Dispersant PAM must work with, not against:

- Retention aids

- Drainage aids

- Defoamers

- Sizing agents

Incorrect sequencing or mismatched charge balance can neutralize the dispersant effect or cause secondary flocculation.

Procurement insight:

A lower-cost dispersant that disrupts system balance often results in higher total chemical consumption.

Key Performance Indicators Procurement Should Evaluate

Instead of relying only on product datasheets, buyers should evaluate dispersant PAM performance using process-relevant indicators.

| Performance Area | What Procurement Should Ask |

|---|---|

| Fiber dispersion | Does it remain stable under high shear? |

| Filler distribution | Is filler evenly retained without agglomeration? |

| Drainage behavior | Does it interfere with drainage aids? |

| Energy efficiency | Does refining power consumption decrease? |

| System stability | Are wet-end fluctuations reduced over time? |

Operational Conditions That Affect Dispersant PAM Performance

pH and Ionic Strength

Most dispersant PAM emulsions perform best in a pH range of 6.5–8.5. Extreme pH or high salt concentrations reduce polymer adsorption efficiency.

Temperature Control

Elevated temperatures accelerate polymer degradation, especially in storage or dilution tanks. This reduces dispersing efficiency and increases dosage demand.

Dosage Control

- Underdosing → incomplete dispersion

- Overdosing → over-dispersion, drainage issues, increased turbidity

This makes on-site optimization and dosage control essential, not optional.

Practical Procurement Recommendations

To minimize risk and maximize long-term value, procurement teams should:

- Request lab trial support for their specific pulp and filler system

- Evaluate PAM on performance stability, not just initial effect

- Require guidance on dilution concentration (typically 0.1–0.3%)

- Confirm compatibility with existing wet-end additives

- Prefer suppliers offering technical follow-up, not only product delivery

A short trial period often reveals more than months of full-scale troubleshooting.

Future Direction: Why Smarter Dispersants Matter

Paper mills are moving toward:

- Higher recycled fiber content

- Lower energy consumption

- Tighter quality tolerances

This increases the need for tailored dispersant PAM emulsions, including:

- Modified copolymers

- Low-toxicity, biodegradable variants

- Systems compatible with digital dosing control

Procurement strategies must evolve accordingly—from buying chemicals to partnering on process stability.

Conclusion: Make Dispersant PAM a Stability Tool, Not a Variable Risk

Dispersant PAM emulsions are not commodity additives. When correctly selected and managed, they become key enablers of stable, efficient, and high-quality paper production.

For procurement teams, the right decision is not choosing the cheapest PAM—but choosing the one that fits the mill’s chemistry, equipment, and operating philosophy.

A knowledgeable supplier and proper evaluation process turn dispersant PAM from a recurring issue into a long-term performance asset.