Flocculants are widely used in drinking water treatment, industrial wastewater treatment, and sludge dewatering. However, the same flocculant may perform very differently under different conditions.

Understanding the key factors that affect flocculant performance helps operators:

- Reduce chemical consumption

- Improve solid–liquid separation

- Achieve stable discharge standards

1. pH Value of Water

The pH value of water is one of the most critical factors affecting flocculant performance.

- Inorganic flocculants (such as PAC and ferric salts) are highly pH-sensitive

- Too low or too high pH can reduce hydrolysis efficiency

- Improper pH leads to weak flocs or slow settling

Each flocculant has an optimal pH range where floc formation is strongest.

2. Water Temperature

Water temperature affects:

- The hydrolysis rate of flocculants

- The formation speed and structure of flocs

At low temperatures:

- Hydrolysis reactions slow down

- Flocs form smaller and looser structures

- Settling time increases

This is why winter operation often requires higher dosage or longer reaction time.

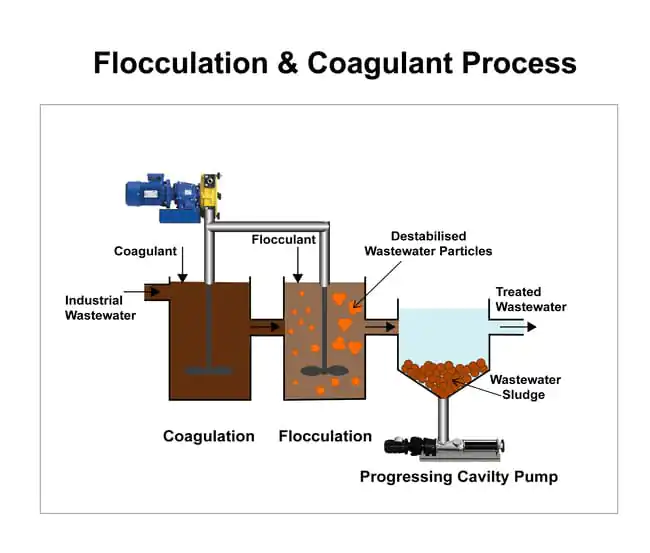

3. Impurity Composition in Water

The size and distribution of impurity particles strongly influence coagulation and flocculation.

- Mixed particle sizes → easier floc formation

- Very fine and uniform particles → poor coagulation

Colloidal particles are stable and difficult to remove without proper destabilization.

4. Type of Flocculant Used

Flocculant selection must match the nature of pollutants.

- Inorganic flocculants:

- Best for colloidal destabilization

- Common examples: PAC, aluminum sulfate, ferric chloride

- Organic polymer flocculants:

- Used for adsorption and bridging

- Improve floc size and settling speed

When flocs are small or loose, combined use is often required.

5. Flocculant Dosage

Flocculant dosage directly affects treatment efficiency.

- Insufficient dosage → incomplete destabilization

- Excessive dosage → restabilization of particles

The optimal dosage must be determined by jar testing based on real water quality.

6. Flocculant Dosing Sequence

The order of dosing is especially important when using inorganic and organic flocculants together.

General rules:

- Inorganic flocculant first, organic flocculant second

- For particles larger than 50 μm:

- Organic flocculant first (bridging)

- Inorganic flocculant second (charge neutralization)

Incorrect dosing sequence can significantly reduce efficiency.

7. Hydraulic and Mixing Conditions

Hydraulic conditions control floc growth and stability.

- Rapid mixing stage:

- Ensures even dispersion of flocculant

- Reaction stage:

- Requires gentle stirring

- Prevents floc breakage

- Allows flocs to grow fully

Gradual reduction of stirring intensity and sufficient reaction time are essential.

Conclusion

Flocculant performance is not determined by chemical type alone. It depends on pH, temperature, water composition, flocculant selection, dosage, dosing order, and hydraulic conditions.

Optimizing these factors ensures:

- Better treatment efficiency

- Lower operating cost

- Stable and compliant effluent quality