In industrial and municipal wastewater treatment, the F/M ratio (Food to Microorganism ratio) is a key indicator of balance between organic load and microbial activity.

When the F/M ratio becomes too high, it can seriously affect effluent quality and trigger a series of operational problems.

Understanding its meaning, causes, and impacts is essential for stable system operation.

What Is the F/M Ratio and What Affects It?

The F/M ratio represents the relationship between incoming organic matter and the amount of microorganisms available to treat it.

It is mainly defined as the ratio of influent BOD load to the mass of activated sludge in the aeration tank.

Formula:

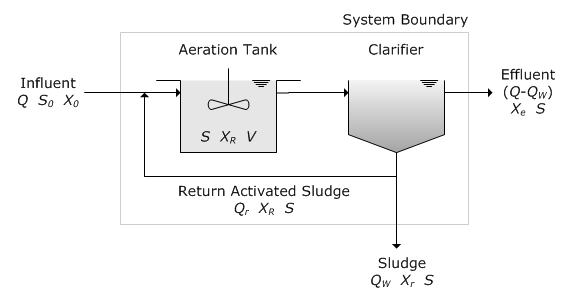

F/M = Q × S₀ / (V × X)

Where:

- Q = influent flow rate

- S₀ = influent organic concentration (BOD)

- V = aeration tank volume

- X = mixed liquor suspended solids (MLSS)

The F/M ratio increases rapidly when:

- Influent flow rises

- Influent organic concentration increases

- Sludge concentration decreases

These changes can cause load shock and destabilize the treatment system.

Four Negative Impacts of a High F/M Ratio

1. Decline in Effluent Quality

Excessive organic load reduces overall removal efficiency.

Common symptoms include:

- Turbid effluent

- Poor sludge settling

- Suspended solids (SS) exceeding discharge limits

2. Suppressed Nitrification

High F/M conditions favor heterotrophic bacteria.

These bacteria outcompete nitrifying bacteria for oxygen and space, leading to:

- Reduced ammonia oxidation

- Ammonia nitrogen exceedance in the effluent

3. Rapid Drop in Dissolved Oxygen (DO)

Higher organic load increases microbial oxygen demand.

If aeration is not adjusted in time:

- DO drops quickly

- Low-oxygen or anaerobic zones may form

- Biological reactions become unstable

4. Bulking Sludge and Foaming Problems

Excess substrate promotes:

- Non-filamentous bulking

- Floating scum or foam formation

These issues interfere with secondary sedimentation, reduce sludge separation efficiency, and threaten long-term system stability.

Industry Advice

When the F/M ratio rises abnormally, operators should:

- Check influent organic concentration

- Monitor sludge concentration (MLSS)

- Review influent flow fluctuations

Timely adjustment of aeration intensity and sludge discharge rate helps prevent prolonged high-load operation and protects system stability.

Conclusion

The F/M ratio is a core control parameter in activated sludge systems.

A consistently high F/M ratio leads to poor effluent quality, inhibited nitrification, oxygen deficiency, and sludge bulking problems.

By closely monitoring influent conditions and adjusting operational parameters, wastewater treatment plants can maintain a balanced F/M ratio and achieve stable, compliant operation.