Polyacrylamide (PAM) is mainly classified into anionic, cationic, nonionic, and amphoteric types. Among them, anionic polyacrylamide is the most widely used, especially in wastewater sedimentation and sludge treatment.

So, how can you choose the right anionic PAM flocculant? The key lies in understanding molecular weight and hydrolysis degree.

1. Main Applications of Anionic Polyacrylamide

Anionic polyacrylamide is commonly used as:

- A sewage settling agent in industrial and municipal wastewater treatment

- A dewatering agent in coal washing plants

- A flocculant for sand washing and mineral processing wastewater

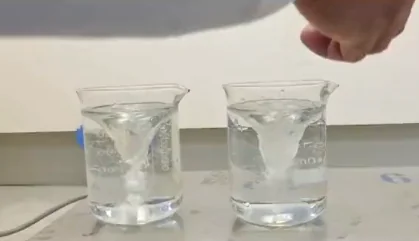

It helps suspended solids aggregate into large, dense flocs, improving settling speed and sludge compaction.

2. How to Choose the Right Molecular Weight

Molecular weight is one of the most important indicators when buying anionic PAM.

- Common molecular weight range: 8 million – 25 million

- Most widely used products:

- 12 million molecular weight

- 18 million molecular weight

In general:

- Lower molecular weight → suitable for wastewater with lower SS

- Higher molecular weight → better bridging ability for fine particles

The final selection should be based on wastewater characteristics and on-site testing.

3. How to Choose the Hydrolysis Degree

The hydrolysis degree of anionic polyacrylamide is usually divided into:

- Low hydrolysis degree

- Medium hydrolysis degree

- High hydrolysis degree

Different industries require different hydrolysis degrees:

- Coal washing plants:

Low hydrolysis degree products often perform better than conventional grades. - Industrial wastewater sedimentation:

Medium hydrolysis degree anionic PAM is the most widely used and suitable for most water qualities.

Medium hydrolysis anionic PAM has the broadest application range and the largest number of users.

4. Other Factors to Consider When Purchasing PAM

In addition to technical parameters, users also care about:

- Product stability

- Dissolution performance

- Actual dosage requirement

- Price and cost-effectiveness

Incorrect selection may lead to high consumption or poor flocculation results. If you are unsure about product type or reasonable pricing, professional guidance is strongly recommended.

HyChron provides technical support and selection assistance to help customers choose high-efficiency anionic polyacrylamide with optimal cost performance.

Conclusion

When purchasing anionic polyacrylamide, the two most critical factors are molecular weight and hydrolysis degree. By understanding and controlling these parameters, users can select a PAM flocculant that delivers efficient flocculation, stable sedimentation, and lower operating costs.

If you are unsure which model to choose or what price is reasonable, feel free to contact HyChron for professional advice and fast response support.