Introduction: Why This Choice Matters in Procurement

When purchasing polyacrylamide (PAM) for water or wastewater treatment, buyers are often asked a simple question:

“Do you want emulsion PAM or powder PAM?”

In reality, this is not a simple product preference, but a procurement decision that affects operating stability, chemical cost, labor input, and treatment risk.

Many plants experience performance fluctuations, rising chemical consumption, or repeated supplier changes—not because PAM “does not work,” but because the selected form does not match the plant’s operating conditions.

This article is written specifically for procurement managers, plant engineers, and technical decision-makers, helping you choose the right PAM form based on real operating logic, not sales language.

Step 1: Understand What You Are Really Buying — Active Polymer, Not “Form”

From a purchasing standpoint, PAM should never be compared by price per ton alone.

The key metric is cost per kilogram of active polymer delivered into the process.

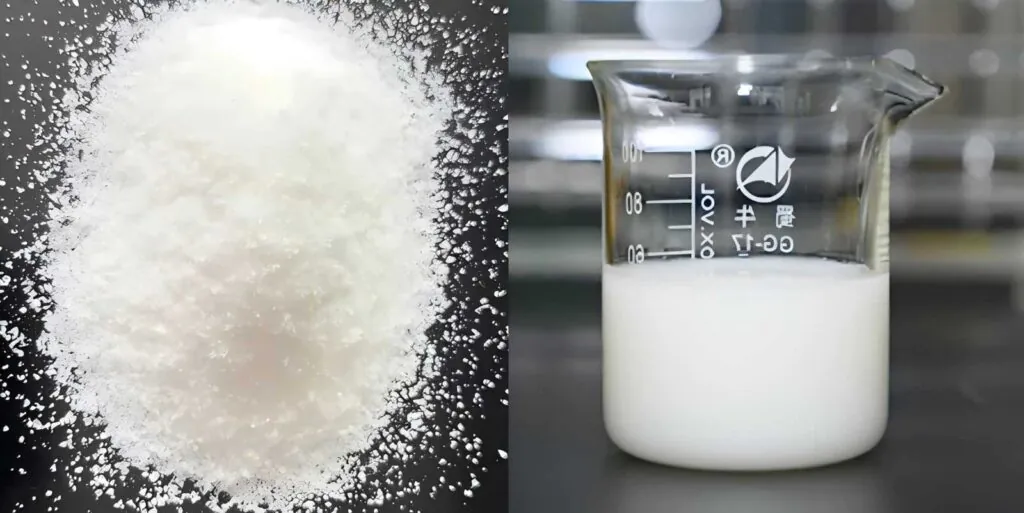

- Powder PAM: typically 85–95% active polymer

- Emulsion PAM: typically 25–50% active polymer

If two suppliers quote similar prices per ton, but one product has half the active content, the real chemical cost may be significantly higher, even before considering logistics and handling.

Procurement takeaway:

Always convert supplier quotes to cost per kg of active polymer, not product weight.

Step 2: Match PAM Form to Your Plant’s Operational Reality

When Powder PAM Is a Better Procurement Choice

Powder PAM is often the right option when:

- The plant operates continuously and stably

- There is trained staff for polymer preparation

- A proper powder make-down unit is already installed

- Chemical storage space is limited

- Freight cost is a major concern

From a pure material-efficiency standpoint, powder PAM usually offers lower cost per unit of active polymer.

However, this advantage only holds if solution preparation is done correctly and consistently.

When Emulsion PAM Reduces Operational Risk

Emulsion PAM is often chosen not because it is “stronger,” but because it is easier to use correctly.

It is especially suitable when:

- Staffing is limited or operators rotate frequently

- Startup and shutdown occur often

- Consistent solution quality has been difficult to maintain

- Dosing systems are automated and require fast response

In many municipal and industrial plants, procurement teams select emulsion PAM to reduce hidden costs related to operator error, unstable floc formation, or compliance risks.

Step 3: Consider the Hidden Costs Beyond Product Price

From a buyer’s perspective, the real cost of PAM includes more than the invoice.

Powder PAM: Hidden Risk Factors

- Incomplete dissolution leading to higher dosage demand

- Over-shearing during mixing, reducing polymer efficiency

- Solution aging causing performance decline

- Line blockage due to “fish-eyes” or gels

These issues often result in higher actual consumption, even if the unit price is lower.

Emulsion PAM: Operational Cost Trade-Off

- Higher freight cost due to lower active content

- Requires proper inversion control

- Oil phase handling considerations

However, many plants find that lower labor demand and stable performance offset these disadvantages.

Procurement insight:

If your plant has experienced repeated polymer-related issues, emulsion PAM often delivers lower total cost of ownership, even if the product price is higher.

Step 4: Avoid Common Procurement Mistakes

Mistake 1: Switching Forms Without Re-Testing

Changing from powder to emulsion (or vice versa) without recalculating active dosage often leads to:

- Flocculation failure

- Sludge dewatering instability

- Overdosing complaints

Best practice:

Always conduct jar tests and short on-site trials when switching PAM form or supplier.

Mistake 2: Ignoring Solution Shelf Life

- Powder PAM solutions degrade over time

- Emulsion PAM solutions also lose activity after inversion

Procurement contracts should clearly define:

- Recommended solution concentration

- Maximum solution age

- Technical support during commissioning

Step 5: What Procurement Should Require From Suppliers

To reduce risk, buyers should request technical clarity, not just pricing.

A qualified PAM supplier should provide:

- Ionic type and charge density

- Molecular weight range

- Active content specification

- Recommended preparation method

- Typical dosage range for similar applications

- On-site or remote technical support

Final Decision Logic for Buyers

Instead of asking “Which PAM is cheaper?”, procurement should ask:

- Which form fits our operation and staffing?

- Which option gives stable performance with minimal intervention?

- Which supplier supports testing and optimization, not just delivery?

In many cases:

- Powder PAM wins on material efficiency

- Emulsion PAM wins on operational reliability

The correct choice depends on your plant, not the product brochure.

Conclusion: Make PAM a Controlled Input, Not a Variable Risk

Polyacrylamide should be a predictable, controllable input in water treatment—not a recurring problem.

By aligning PAM form selection with plant operations, staffing, and process stability, procurement teams can reduce chemical waste, improve compliance confidence, and avoid repeated supplier changes.

A short technical evaluation upfront almost always saves months of troubleshooting later.