Polyacrylamide (PAM) is one of the most effective flocculants for sewage treatment. When the right PAM type is selected and applied correctly, it can significantly improve solid–liquid separation, reduce sludge volume, and lower overall treatment costs. Understanding how to use PAM properly is essential for stable and efficient sewage treatment operations.

Why PAM Is Widely Used in Sewage Treatment

PAM works by promoting flocculation, allowing fine suspended particles, organic matter, and heavy metal ions to form larger, heavier flocs. These flocs settle faster, making downstream separation and dewatering more efficient.

Key benefits for sewage treatment plants:

- Faster sedimentation

- Lower sludge moisture content

- Reduced chemical consumption

- Improved effluent quality

1. Choosing the Right PAM Type Matters

Not all PAM products perform the same. PAM differs by:

- Ionic type (anionic, cationic, nonionic)

- Molecular weight

Each sewage system has unique characteristics. Selecting the wrong PAM type may result in poor floc formation or excessive chemical usage.

👉 Professional recommendation:

Analyze sewage parameters such as SS concentration, pH, and organic content before selecting a PAM grade.

2. Small-Scale Testing Saves Cost

Before full-scale application, jar testing or pilot testing is strongly recommended.

Benefits of testing:

- Identify the optimal PAM dosage

- Avoid overdosing and chemical waste

- Improve treatment stability

This step helps operators achieve the best results with the lowest operating cost.

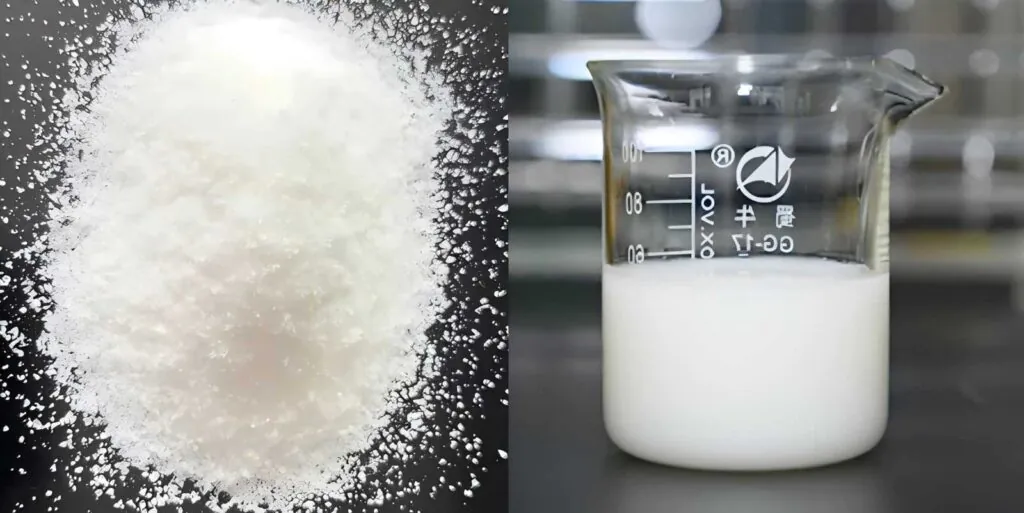

3. Proper PAM Solution Preparation Ensures Performance

PAM must be fully dissolved before use.

Recommended preparation method:

- Solution concentration: 0.1%–0.2%

- Add PAM powder slowly into water while stirring

- Mix gently until fully dissolved

- Use the solution within 24 hours

Proper preparation allows PAM molecular chains to fully expand, ensuring maximum flocculation efficiency.

4. Correct Injection Improves Flocculation Efficiency

Selecting the Injection Point

Choose a location with:

- Stable flow

- Good mixing conditions

This ensures PAM disperses evenly throughout the sewage.

Injection Control

- Add the solution slowly and continuously

- Avoid sudden high concentrations

- Adjust dosage based on real-time results

Controlled injection leads to stronger flocs and better sedimentation.

5. Mixing and Floc Formation Process

After injection:

- PAM interacts with suspended particles

- Fine solids form visible flocs

- Flocs settle efficiently in sedimentation tanks

⚠️ Avoid excessive mixing, as it may break flocs and reduce treatment efficiency.

6. Post-Treatment and Performance Monitoring

Sludge Separation

Settled sludge is removed and sent for further dewatering or disposal. Proper PAM usage can significantly reduce sludge volume.

Water Quality Monitoring

Regularly monitor:

- COD

- BOD

- SS

Monitoring helps maintain stable treatment results and optimize chemical usage.

7. Safety, Environment, and Equipment Protection

- Use gloves and eye protection when handling PAM

- Avoid direct contact with powder or solution

- Store PAM in a dry, cool place

- Maintain dosing and mixing equipment regularly

These practices ensure safe operation and long-term system stability.

Conclusion: Get the Best Results from PAM in Sewage Treatment

Using Polyacrylamide (PAM) correctly can greatly improve sewage treatment efficiency while reducing operating costs. By selecting the right PAM type, optimizing dosage through testing, and following proper preparation and dosing procedures, treatment plants can achieve reliable performance and meet discharge standards with confidence.

👉 A reliable PAM supplier and proper technical guidance make all the difference.