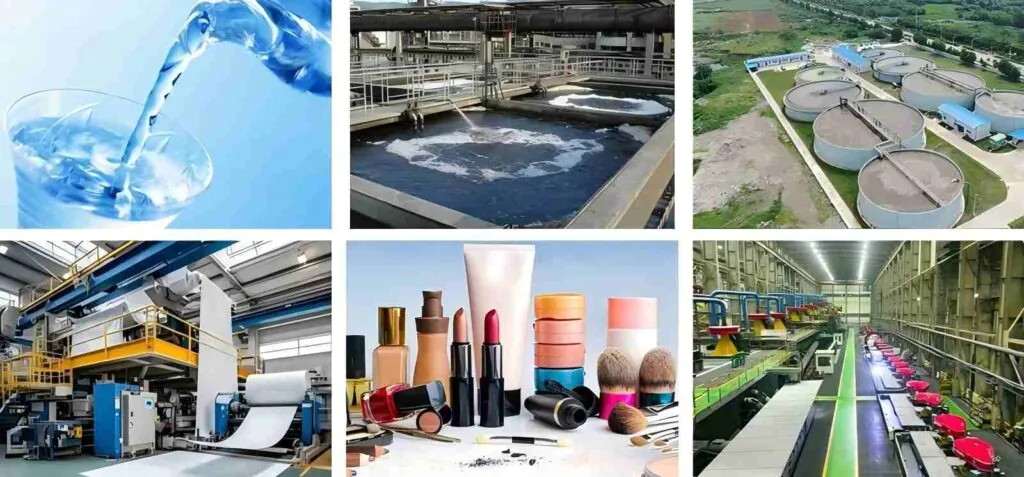

When people mention Polyaluminum Chloride (PAC), most think about drinking water or wastewater treatment. But PAC is far more than a water purification chemical. Thanks to its strong coagulation ability, stability, and adaptability, PAC is now used in many industrial fields where process control, purification, and material performance are important.

PAC in Oil Drilling Operations

In the oil and gas industry, PAC is widely used in drilling fluid treatment. Drilling fluids, often called drilling muds, are essential for cooling the drill bit, carrying rock cuttings to the surface, and maintaining wellbore stability. PAC is added to adjust the rheological properties of these fluids.

By increasing fluid viscosity, PAC helps keep drill cuttings suspended and prevents them from settling at the bottom of the well. It also improves filtration control, reducing fluid loss into surrounding rock formations. This helps maintain wellbore integrity and lowers the risk of drilling accidents. Using PAC in drilling fluids can improve operational safety, reduce equipment wear, and enhance overall drilling efficiency.

PAC in the Leather Tanning Industry

PAC also plays an important role in leather processing. During tanning, raw animal hides are treated to become durable and resistant to decay. PAC reacts with collagen fibers in the hide and forms stable complexes with proteins, supporting the tanning process.

Compared with some traditional tanning agents, PAC can help produce leather with better strength and flexibility. It can also reduce the generation of certain wastes during processing, making the tanning operation cleaner and more efficient. For leather manufacturers aiming to improve product quality while controlling environmental impact, PAC is an attractive option.

PAC in Pharmaceutical Production

In pharmaceutical manufacturing, product purity is critical. PAC is used in certain clarification and purification steps to remove suspended particles and colloidal impurities from solutions containing active ingredients. Its coagulation properties help separate unwanted substances, making downstream filtration and processing easier.

For example, during the production of some antibiotic or fermentation-based products, PAC can assist in clarifying intermediate solutions. This supports stable production and helps ensure that final products meet strict quality standards. As purification requirements continue to increase, PAC is gaining attention as a practical and cost-effective processing aid.

PAC in Paper and Textile Industries

In papermaking, PAC can be used as a retention aid. It helps retain fine fibers, fillers, and pigments in the paper sheet, improving paper quality and reducing material loss. Better retention means higher production efficiency and lower wastewater load.

In the textile industry, PAC is often applied in wastewater treatment. Textile effluents usually contain dyes and organic pollutants that are difficult to remove. PAC helps coagulate these substances, making them easier to separate from water and supporting compliance with discharge standards.

Expanding Opportunities for PAC Applications

The growing use of PAC in different industries shows its value as a multifunctional industrial chemical. Its ability to assist in solid–liquid separation, improve process stability, and reduce operational costs makes it attractive for many production systems. As environmental standards become stricter and industries focus more on efficiency, the demand for high-performance coagulants like PAC continues to rise.

If you are exploring PAC for applications beyond traditional water treatment, choosing the right grade and technical support is important. Different industries require different PAC specifications. Our team can recommend suitable PAC products based on your process needs and provide samples for testing. Feel free to contact us to discuss your application in detail.