Mineral processing wastewater usually contains a high concentration of fine mineral particles and sludge. To achieve efficient solid–liquid separation, polyacrylamide (PAM) is widely used as a flocculant in mineral processing sewage treatment systems.

In most cases, anionic polyacrylamide or nonionic polyacrylamide is selected for mineral processing wastewater sedimentation. The final product model and dosage should be determined through laboratory tests based on the treatment process and wastewater characteristics.

Proper use of PAM not only improves flocculation efficiency and treats ore-washing sludge effectively, but also helps maintain product quality, increase operational efficiency, and reduce overall treatment costs.

1. Role of Polyacrylamide in Mineral Processing Wastewater Treatment

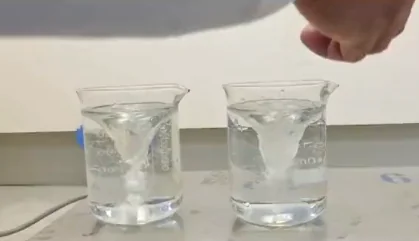

In mineral washing processes, large amounts of fine particles remain suspended in water and are difficult to settle naturally. PAM works by adsorbing and bridging these particles, forming larger and heavier flocs that settle faster.

This improves clarification efficiency and reduces the load on downstream equipment such as thickeners and filter presses.

2. Selection of PAM Type and Dosage

The selection of polyacrylamide should be based on:

- Type of mineral and particle size

- Slurry concentration and pH

- Treatment process design

- Required settling or dewatering performance

Anionic or nonionic PAM is commonly used, but the optimal molecular weight and ionic degree must be confirmed through jar tests or on-site trials.

With correct selection, PAM can achieve better treatment results with lower dosage, improving cost-effectiveness.

HyChron provides free product selection services to help customers choose the most suitable PAM with high efficiency and minimal consumption.

3. Precautions for Using Polyacrylamide

Correct preparation and use of PAM are critical for achieving stable performance.

3.1 Proper Dissolution

PAM must be evenly dispersed in water during preparation. Poor dispersion can cause agglomeration and form “fish eyes,” which increases dissolution time and reduces effectiveness.

3.2 Water Temperature Control

Using warm water can accelerate dissolution. However, excessive temperature may cause polymer degradation and reduce viscosity.

Recommended water temperature: below 50 °C.

3.3 Stirring Intensity

Gentle stirring helps dissolution, but excessive agitation can break polymer chains and reduce flocculation efficiency.

A propeller or ship-type agitator is recommended.

3.4 Solution Storage Time

Prepared PAM solutions should be used within 48 hours. Longer storage may lead to viscosity loss and reduced treatment performance.

4. Storage Guidelines for Polyacrylamide

Proper storage helps maintain product quality and performance:

- Store PAM in a cool, dry, and well-ventilated place

- Do not stack bags directly on the ground; use pallets to prevent moisture absorption

- Stack height should generally not exceed 10 layers

- Unused product must be sealed tightly to avoid exposure to air

- Follow the principle of first in, first out (FIFO) during use

Conclusion

Polyacrylamide plays a vital role in mineral processing wastewater treatment by improving flocculation, enhancing sedimentation, and reducing treatment costs. Through proper product selection, correct preparation, and standardized operation, PAM can deliver stable and efficient treatment results.

With professional selection support and controlled application, mineral processing plants can achieve better wastewater management and more sustainable production.