Many users find that polyacrylamide flocculant performs differently under real operating conditions. This is because PAM efficiency is influenced by process design, operating parameters, and water quality.

polyacrylamide flocculant basics

Key Factors Affecting PAM Performance

1. Treatment Process and Equipment

Different equipment requires different floc properties. A polymer suitable for sedimentation may not work well in dewatering systems.

PAM application in sedimentation and sludge dewatering

2. Operating Conditions

- pH

- Mixing intensity

- Reaction time

Improper mixing can destroy flocs or prevent full polymer activation.

3. Polymer Selection

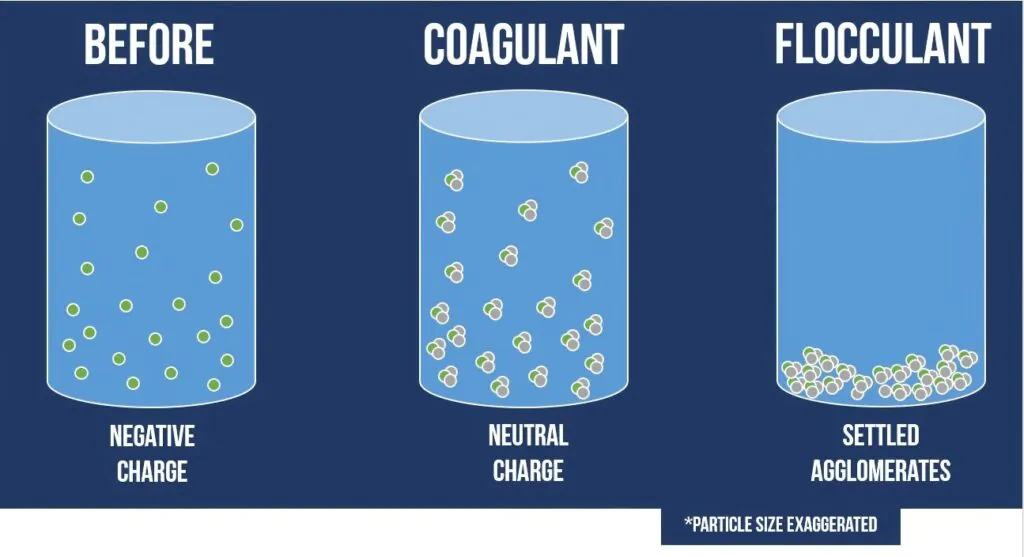

Anionic, cationic, and nonionic PAMs behave differently depending on wastewater composition.

4. Dosage Control

Overdosing can cause:

- Poor separation

- Increased turbidity

- Higher operating costs

Underdosing leads to weak floc formation.

PAM application in sedimentation and sludge dewatering

On-Site Optimization Practices

- Conduct jar tests before full-scale use

- Adjust dosage gradually based on observation

- Monitor floc size, settling speed, and effluent clarity

- Optimize polymer preparation concentration

These steps help stabilize treatment results and reduce chemical waste.

Value for Buyers and Operators

Optimizing PAM use improves:

- Water recovery rate

- Sludge handling efficiency

- Long-term operating cost control

From a procurement perspective, consistent performance is more valuable than low unit price.

Conclusion

reliable polyacrylamide flocculant manufacturer

Polyacrylamide flocculant performance depends on proper selection, dosing, and operational control. By optimizing these factors on site, users can achieve stable treatment efficiency and maximize return on investment.