In modern wastewater treatment, Enhanced Biological Phosphorus Removal (EBPR) is widely used in municipal and industrial systems. Many factors affect EBPR performance, such as temperature, pH, influent substrate, HRT, sludge age, and loading rate. Among them, dissolved oxygen (DO) is one of the most important.

This article explains how DO affects each stage of biological phosphorus removal and offers tips for better control.

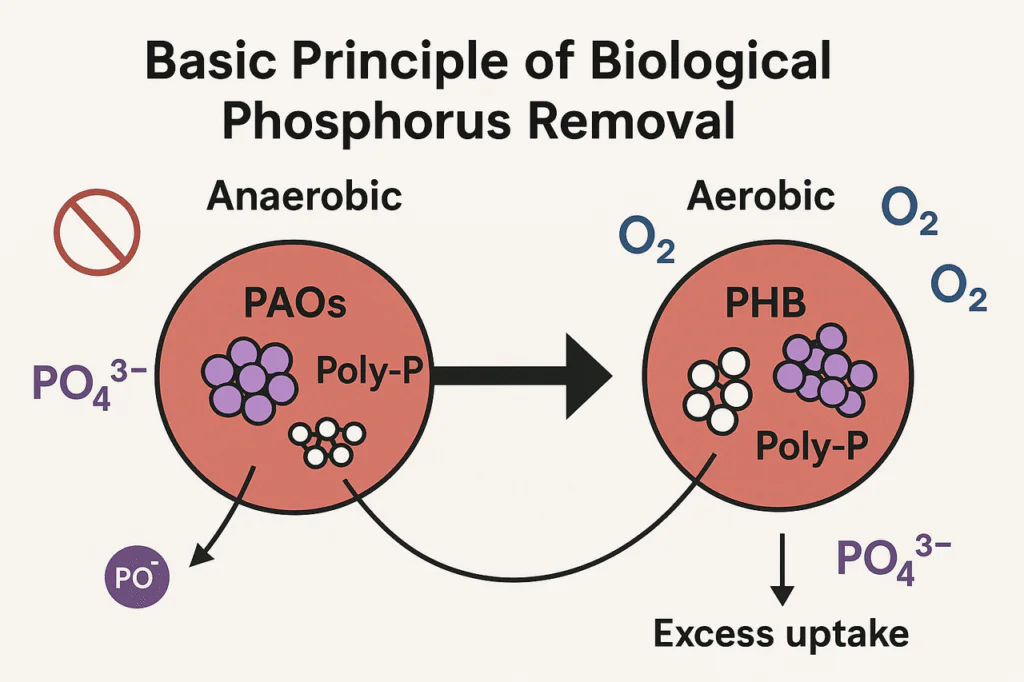

🔬 Basic Principle of Biological Phosphorus Removal

EBPR depends on polyphosphate-accumulating organisms (PAOs). These microbes work in two steps:

- Anaerobic phase: PAOs break down polyphosphate (Poly-P) inside their cells and release phosphorus. They also store carbon in the form of PHB (polyhydroxybutyrate).

- Aerobic phase: PAOs use oxygen to break down PHB for energy. Then they take in phosphorus from the water and store it again.

🌡 DO’s Effect in the Anaerobic Phase

In this phase, the DO level must be very low. It should stay below 0.2 mg/L. If DO is too high or if too much nitrate enters this zone (due to high return flow), problems may occur:

- Non-PAO bacteria consume the carbon source first, reducing PAO energy.

- PHB storage is limited, so less phosphorus is removed later.

- The system may enter a “carbon-limited” state, hurting overall performance.

📌 Optimization Tips:

- Keep anaerobic DO ≤ 0.2 mg/L.

- Maintain return sludge ratio at 50%–100%, to avoid nitrate overload and “fake anaerobic” conditions.

⚙ DO’s Effect in the Aerobic Phase

In this stage, enough oxygen is essential. PAOs use oxygen to break down PHB and take in phosphorus. Recommended DO in the aerobic zone is 2–3 mg/L, with at least 1.5 mg/L at the outlet.

If DO is too low:

- The system becomes oxygen-limited.

- PAOs cannot take in phosphorus efficiently.

- Nitrification slows down, which may lead to carbon mismatch for denitrification.

If DO is too high:

- May cause cell aging and high energy use.

- Watch for this under low MLSS or light loading conditions.

📌 Optimization Tips:

- Adjust blower speed or aeration time based on actual load.

- Use online DO meters and auto-control systems for better stability.

🔁 Coordinating Return Ratio and DO Control

If aerobic nitrification works well but return ratio is too low, nitrate may flow into the anaerobic zone, hurting phosphorus release.

Recommended actions:

- Ensure return ratio meets nitrate backflow needs.

- Test nitrate in secondary effluent to check for leakage.

- Monitor DO in returned sludge to prevent redox conflict.