When selecting Polyaluminium Chloride (PAC), many buyers focus heavily on alumina (Al₂O₃) content.

A common assumption is: the higher the alumina content, the better the performance. But in real water treatment operations, this is not always true.

Understanding how alumina content actually affects PAC performance helps avoid overdosing, poor flocculation, and unnecessary chemical cost.

1. What Does Alumina Content in PAC Mean?

Alumina content represents the active coagulating component in PAC. In general:

- Higher alumina → higher charge density

- Higher alumina → higher relative density

- Higher alumina → higher viscosity

Because alumina drives charge neutralization and floc formation, it plays a key role in coagulation efficiency.

👉 Related reading: What Is Polyaluminium Chloride (PAC)?

2. Common PAC Alumina Specifications in the Market

PAC is usually classified by alumina (Al₂O₃) percentage, such as:

- 30% PAC

- 28% PAC

- 26% PAC

- 24% PAC

Many water plants automatically prefer 30% PAC, assuming it delivers the strongest performance in all conditions.

However, field experience shows that matching PAC grade to water quality is far more important than choosing the highest content.

3. Why High-Alumina PAC May Fail in Low-Turbidity Water

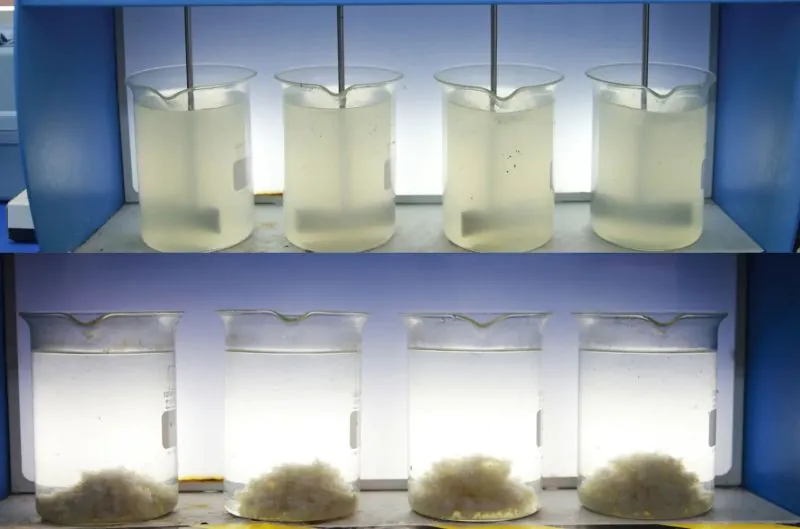

When high-alumina PAC is used in low-turbidity or lightly polluted water, operators sometimes observe:

- Poor settling

- Suspended solids remaining in water

- Weak or slow floc formation

This is often misunderstood as a “product quality issue,” but the root cause is usually process mismatch.

4. The Real Reasons Behind Poor Performance

4.1 Water pH Is Too Low

Higher alumina PAC products are generally more acidic. If the raw water is already acidic:

- PAC hydrolysis becomes unstable

- Charge neutralization is incomplete

- Effective floc formation cannot occur

4.2 Suspended Solids Are Too Light

In low-turbidity water:

- Particles are small and light

- High-charge PAC cannot effectively bridge particles

- Flocs lack enough mass to settle

In such cases, medium or low alumina PAC, or PAC combined with polymer flocculants, often performs better.

5. Does Higher Alumina Content Still Have Advantages?

Yes—but only in the right conditions. High-alumina PAC works best when:

- Turbidity is high

- Suspended solids concentration is high

- Fast flocculation is required

- pH is properly adjusted

In these cases:

- Flocculation is faster

- Flocs are denser

- Chemical dosage can be reduced

6. How to Choose the Right PAC Alumina Content

Instead of asking “Which PAC has the highest alumina?”, buyers should ask:

- What is the raw water pH?

- What is the turbidity level?

- Are particles light or heavy?

- Is sludge settling or flotation used?

Correct selection improves:

- Treatment stability

- Chemical efficiency

- Operating cost control

Conclusion

Higher alumina content in PAC does not automatically mean better performance. PAC efficiency depends on:

- Alumina content

- Water pH

- Turbidity

- Particle characteristics

Choosing the right PAC grade based on actual water conditions delivers better flocculation, lower cost, and more stable operation.