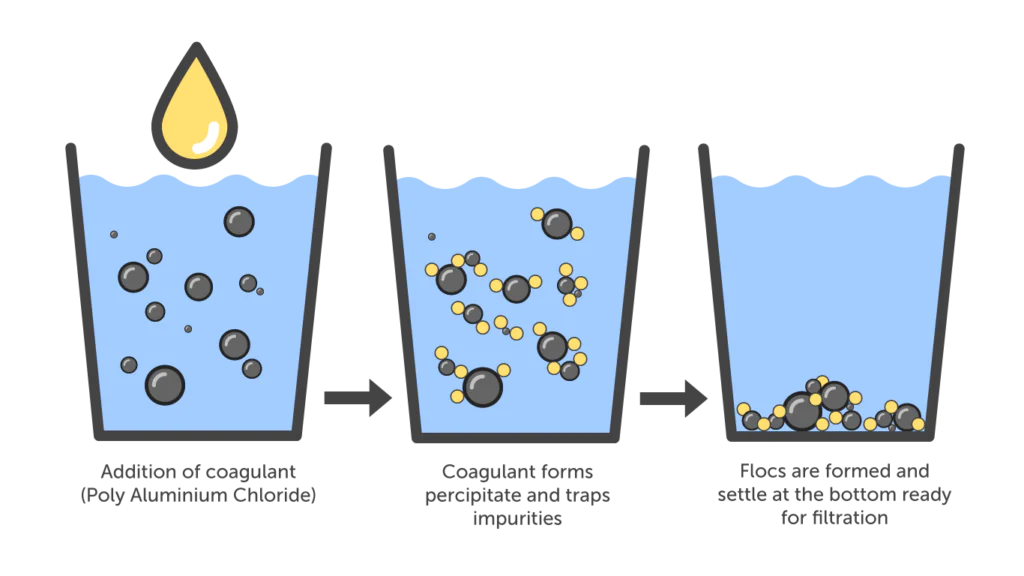

As a widely used inorganic coagulant, polyaluminum chloride (PAC) plays a key role in municipal and industrial wastewater treatment. However, during real plant operation, operators often encounter problems such as floating alum flocs, cloudy effluent, excessive sludge accumulation, bubbles, and unstable flocculation.

This article summarizes the most common PAC field problems, analyzes their causes, and provides practical, on-site solutions to help stabilize treatment performance and reduce operating risks.

1. Large Alum Flocs Floating on the Sedimentation Tank Surface

Problem Description

Large alum flowers rise to the surface instead of settling, reducing sedimentation efficiency.

Main Cause

- Overdosing of polyaluminum chloride

- Excessive floc size with trapped gas or buoyancy

Practical Solutions

- Appropriately reduce PAC dosage

- Strengthen sludge discharge operations to prevent accumulation

- Monitor floc size and settling behavior after adjustment

2. Fine Flocs Floating in Clear Water Zone and Cloudy Effluent

Problem Description

Small flocculent particles float in the clarified zone, causing high turbidity in effluent.

Main Cause

- Excessive water flow

- Insufficient PAC dosage, leading to incomplete charge neutralization

Practical Solutions

- Reduce influent water flow if possible

- Increase PAC dosage gradually until stable flocculation is achieved

- Re-check rapid mixing efficiency

3. Rapid Increase of Sludge Layer Height and Rising Effluent Turbidity

Problem Description

The sludge layer rises quickly, and effluent turbidity increases.

Main Cause

- Insufficient sludge discharge

- Sludge accumulation inside the system

Practical Solutions

- Shorten sludge discharge intervals

- Extend each sludge discharge duration

- Maintain a stable sludge blanket height

4. Excessive Bubbles in the Clear Water Area

Problem Description

Large amounts of bubbles appear in the clear water zone, disturbing clarification.

Main Cause

- Excessive addition of lime water

- Long-term sludge accumulation leading to anaerobic fermentation and gas generation

Practical Solutions

- Reduce lime dosage

- Shut down the system temporarily

- Perform manual sludge discharge and degassing

5. “Turning Flocs” Phenomenon During PAC Operation

Problem Description

Formed flocs break apart, re-suspend, or fail to settle properly.

Main Causes

- High water temperature

- Excessive water flow rate

- Interrupted chemical dosing

- Delayed sludge discharge

- Sludge layer too thick

Practical Solutions

- Control water temperature within normal operating range

- Reduce hydraulic load

- Ensure continuous and stable PAC dosing

- Discharge sludge in time

- Keep sludge layer height under control

Operational Tips to Prevent PAC Problems

- Always adjust PAC dosage based on real-time water quality

- Avoid long-term sludge accumulation

- Ensure stable hydraulic conditions

- Combine PAC with proper pH control and auxiliary chemicals when necessary

Conclusion

Most PAC-related problems are not product quality issues, but the result of dosage imbalance, sludge management failure, or unstable operating conditions.

By understanding these common problems and applying targeted solutions, polyaluminum chloride can deliver stable flocculation, efficient sedimentation, and clear effluent, ensuring long-term, cost-effective wastewater treatment performance.