Polyaluminum chloride (PAC) is one of the most widely used inorganic coagulants in water and wastewater treatment. However, many plants report clogging problems during the PAC dosing process, especially in:

- Metering pipes

- Filters

- Dosing tanks

Understanding the real causes helps avoid shutdowns and chemical waste.

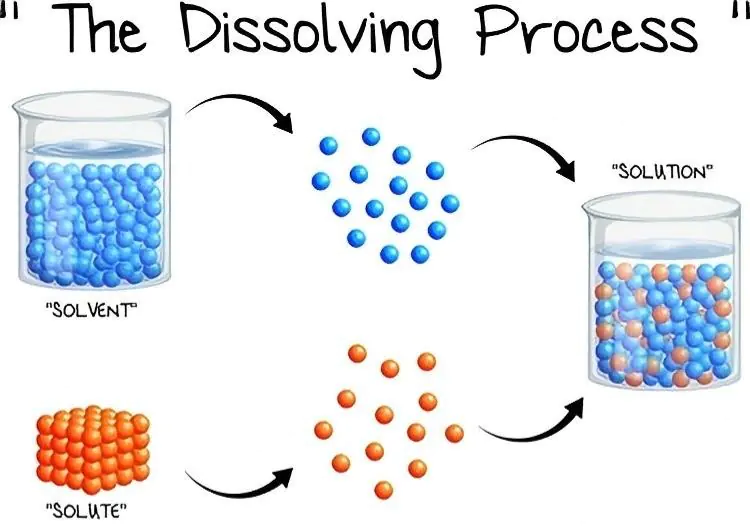

1. PAC Is Not Fully Dissolved

Typical Mistake

PAC powder is added too fast or with insufficient water.

Result

- Undissolved particles block pipes

- Filters clog quickly

Correct Practice

- Dissolution ratio: PAC : Water = 1 : 3

- Add PAC slowly

- Continuous stirring until fully dissolved

2. Excessive PAC Dosage

Overdosing does not improve coagulation.

Instead, it:

- Increases viscosity

- Forms sticky precipitates

- Causes blockage

Solution:

- Reduce dosage

- Re-test using jar test

3. Insoluble Matter in PAC

PAC contains a small amount of water-insoluble substances.

Important facts:

- Lower Al₂O₃ content → higher insoluble matter

- Industrial-grade PAC contains more residue

This does not always affect treatment, but may clog fine filters.

Solutions

- Increase dilution water

- Improve stirring speed

- Use proper filtration before dosing

4. Operational and Equipment Issues

Clogging may also come from:

- Small-diameter dosing pipes

- Dead zones in tanks

- Poor pump selection

Solution:

- Optimize pipeline design

- Avoid sharp bends

- Match pump capacity to PAC viscosity

Final Summary

PAC clogging during dosing is a common but preventable problem in water and wastewater treatment systems. In most cases, clogging is caused by poor dissolution, excessive dosage, insoluble matter, or unsuitable equipment design, rather than the PAC product itself.

By controlling dilution ratios, improving stirring efficiency, selecting proper-grade PAC, and optimizing dosing systems, operators can effectively eliminate clogging risks and ensure stable, efficient coagulation performance.

Proper PAC handling not only protects equipment but also improves treatment results and reduces long-term maintenance costs.