In modern water treatment, choosing the right coagulant directly affects treatment efficiency, chemical cost, and final water quality. Polyaluminium Chloride (PAC) is widely used because it reacts quickly and forms strong flocs. To use PAC more effectively, it is important to understand how it works in water at the chemical level.

When PAC is added to water, it immediately begins a process called hydrolysis. PAC is not a simple salt. It is a polymeric aluminum compound. After dissolving, it releases aluminum ions and pre-formed polymeric aluminum species. These components react with water to form different hydroxo-aluminum complexes such as Al(OH)²⁺, Al(OH)₂⁺, Al(OH)₃, and larger polymer structures. These positively charged species are the key to PAC’s strong coagulation ability.

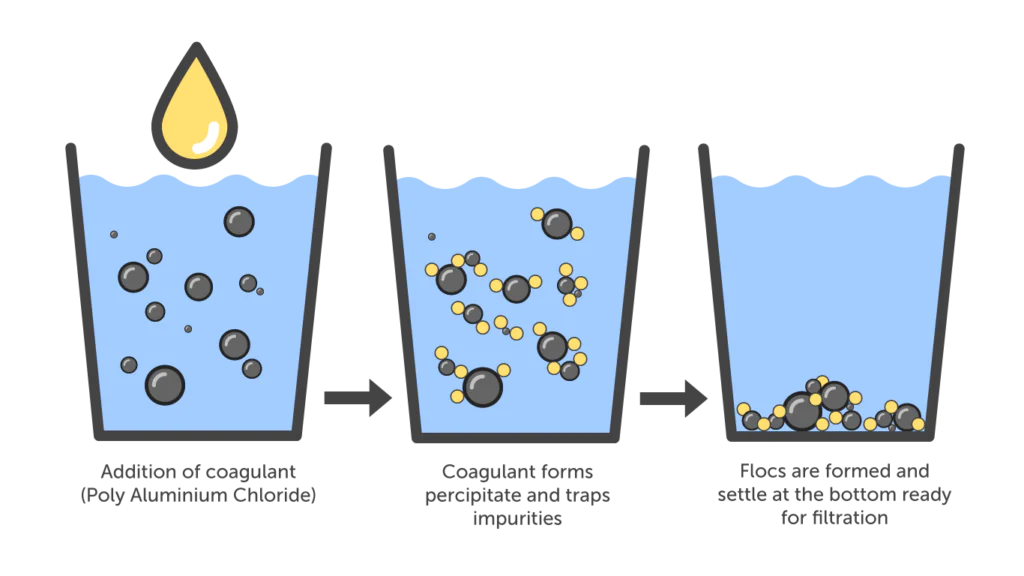

Most impurities in water, including clay, silt, organic matter, and colloids, carry negative surface charges. Because of this charge, particles repel each other and stay stable in suspension. The positively charged hydroxo-aluminum complexes produced by PAC neutralize these negative charges. Once the charge is neutralized, particles can come closer together instead of pushing away from each other.

After charge neutralization, tiny particles begin to collide and stick together. At this stage, polymeric aluminum species also create a “bridging” effect between particles. Small particles combine into larger aggregates called flocs. These flocs become heavy enough to settle or be removed by filtration. This is the core mechanism that allows PAC to clarify water efficiently.

How pH Affects PAC Reactions

pH is one of the most important factors influencing PAC performance. Under very acidic conditions, excess hydrogen ions reduce the formation of effective hydroxo-aluminum species. This weakens charge neutralization and lowers coagulation efficiency. Under very alkaline conditions, aluminum may form insoluble aluminum hydroxide too quickly, reducing the number of active polymeric species in solution.

For most water treatment systems, PAC performs best within a pH range of 5 to 9. In this range, the balance of aluminum species is ideal for both charge neutralization and floc growth. This is why many treatment plants adjust pH before or during PAC dosing.

Temperature Influence on PAC Performance

Temperature also affects how fast PAC reacts. At higher temperatures, molecules move faster and chemical reactions occur more quickly. This can improve floc formation speed and settling performance. However, extremely high temperatures may destabilize some polymeric aluminum structures, slightly reducing performance.

In cold water conditions, hydrolysis reactions slow down. In these cases, operators often need to optimize dosage or mixing conditions to maintain good coagulation results.

Why Understanding the Mechanism Matters

In real treatment plants, water quality changes every day. Turbidity, organic content, alkalinity, and temperature all vary. Understanding PAC’s reaction mechanism helps operators adjust dosage, pH, and mixing intensity more precisely. This leads to better clarification, lower sludge volume, and reduced chemical waste.

For industrial users, this knowledge also helps when selecting between different PAC grades, such as high-basicity or spray-dried products, depending on raw water conditions and treatment goals.

PAC Optimization Means Lower Cost and Better Water

PAC is more than just a coagulant. Its efficiency comes from its unique polymeric structure and multi-stage reaction process in water. When applied under the right pH and temperature conditions, PAC forms strong, fast-settling flocs and delivers stable treatment performance.

If you are working with difficult raw water, seasonal temperature changes, or strict discharge standards, selecting the right PAC type and optimizing dosing conditions can significantly improve your system.

Need help choosing the right PAC grade for your water quality? Our technical team can recommend suitable products and dosing strategies based on your application.