In water and wastewater treatment, Polyacrylamide (PAM) plays a critical role in sludge dewatering, clarification, and solid-liquid separation. Engineers and plant managers often spend considerable time selecting the right PAM type—cationic, anionic, or non-ionic—based on sludge properties and water chemistry.

However, an overlooked reality exists in many treatment plants: up to 90% of PAM performance can be lost before the polymer even reaches the treatment process. The reason is not poor product quality, but improper polymer preparation.

PAM is a high–molecular-weight polymer. Unlike simple salts, it requires careful dissolution and hydration. Incorrect preparation turns a high-performance flocculant into an expensive but ineffective solution, leading to higher chemical consumption, poor treatment results, and operational frustration.

This article explains why PAM dissolution is so critical, highlights the most common preparation mistakes, and provides a practical guide to achieving maximum polymer efficiency.

Understanding PAM Dissolution: Wetting and Hydration

PAM dissolution is not a simple mixing process. It consists of two essential stages: wetting and hydration.

Polymer Structure: A Coiled Chain

Dry PAM powder contains long polymer chains that are tightly coiled. Although these chains are hydrophilic, water cannot access them unless the powder is properly dispersed.

Stage 1: Wetting

When PAM powder contacts water, its surface absorbs water rapidly and forms a gel layer. If the powder is not dispersed immediately, this gel layer prevents water from entering the core of the particle.

Stage 2: Hydration and Chain Extension

After proper wetting, water penetrates the polymer matrix. The chains gradually uncoil and fully extend in solution. Only at this stage can PAM effectively perform flocculation through particle bridging and charge neutralization.

Key principle:

A fully hydrated PAM solution contains polymer chains that are completely extended and individually available. Any deviation from this state reduces flocculation efficiency.

Five Common PAM Dissolution Mistakes That Destroy Performance

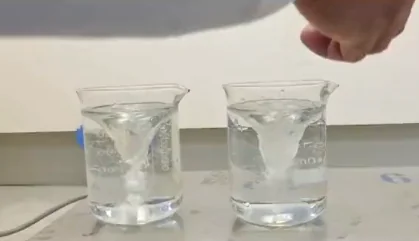

1. Dumping Powder Directly into Water (Fish-Eye Formation)

Adding PAM too quickly or into stagnant water causes large gel clumps known as “fish-eyes.” These clumps have hydrated outer layers but dry cores that never dissolve.

Consequences:

- Large loss of active polymer

- Blocked pipes and dosing equipment

- Unstable and unpredictable dosing concentration

2. Incorrect Mixing Intensity

Too little mixing:

Powder is not dispersed properly, increasing the risk of clumping.

Too much mixing:

Excessive shear breaks polymer chains after hydration, permanently reducing molecular length.

Result:

Shorter chains mean weaker flocs, slower settling, and higher dosage demand.

3. Over-Concentrated Polymer Solution

Preparing PAM at overly high concentrations leaves insufficient space for polymer chains to uncoil. The chains entangle with each other instead of extending fully.

Typical recommended concentration:

0.1%–0.5%

Higher concentrations increase viscosity and reduce flocculation efficiency.

4. Skipping the Aging Time

Even after the powder disappears visually, PAM is not fully hydrated. Polymer chains require 30–60 minutes to reach maximum extension.

Using PAM too early results in:

- Reduced floc strength

- Higher chemical consumption

- Poor sludge dewatering or clarification

5. Poor Water Quality and Equipment Conditions

- High hardness (Ca²⁺, Mg²⁺) can reduce anionic PAM efficiency

- Extreme pH alters polymer charge behavior

- Dirty or rusty tanks consume active polymer prematurely

Operational Impact of Poor PAM Preparation

Improper PAM dissolution causes a chain reaction of operational problems:

- Chemical costs increase due to overdosing

- Weak flocs lead to turbid effluent and poor sludge cakes

- Frequent equipment clogging increases maintenance time

- Misdiagnosis leads to unnecessary product changes instead of process correction

In many cases, plants unknowingly double or triple PAM consumption simply to compensate for preparation losses.

Best Practice Guide for Proper PAM Preparation

Step 1: Preparation Conditions

- Use clean, neutral water

- Confirm correct solution concentration

- Ensure proper mixer size and placement

Step 2: Controlled Powder Addition

- Create a strong vortex

- Slowly sprinkle PAM powder into the vortex

- Avoid dumping powder at once

Step 3: Aging Phase

- Mix gently for 5–10 minutes

- Allow solution to age for 30–60 minutes

- Avoid high shear during aging

Step 4: Transfer and Dosing

- Use low-shear pumps

- Avoid sharp bends in pipelines

- Use prepared solution within 24–72 hours

Advanced Recommendations

- Automated polymer preparation units improve consistency

- Conduct periodic jar tests to verify polymer activity

- Monitor solution stability and viscosity as performance indicator

Conclusion

PAM efficiency does not depend solely on product selection—it begins with correct preparation. Improper dissolution silently consumes budgets, reduces treatment efficiency, and creates unnecessary operational challenges.

By understanding the science behind polymer hydration and following disciplined preparation procedures, wastewater treatment plants can unlock the full value of PAM, reduce chemical consumption, and achieve stable, high-performance results.