Polyacrylamide (PAM) is a widely used flocculant in water treatment and sludge dewatering. When prepared and dosed correctly, PAM can greatly improve solid–liquid separation and overall treatment efficiency. This guide explains how to prepare PAM solutions, how to determine proper dosage, and how to use PAM effectively in different treatment processes.

What Is PAM and Why Proper Preparation Matters

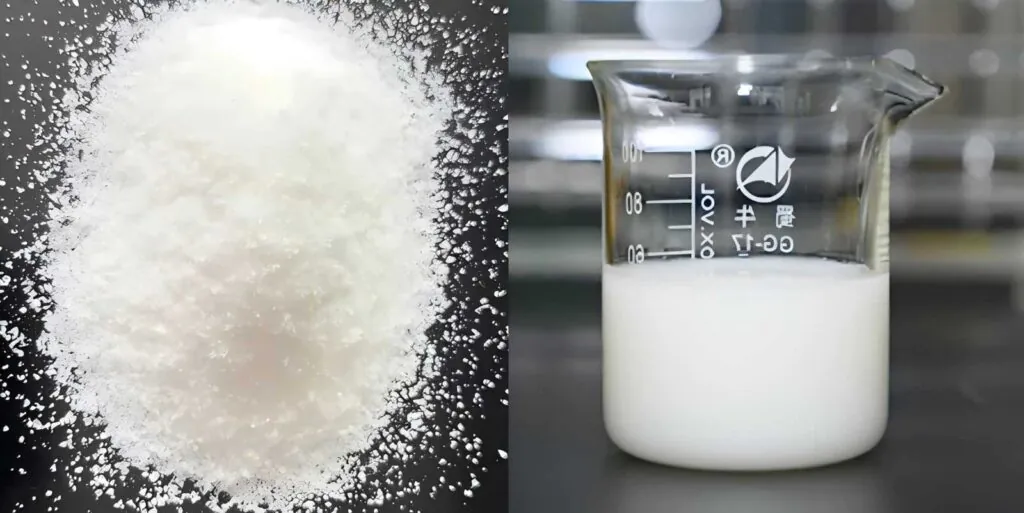

PAM is supplied as a dry powder. It must be dissolved in water before use. Improper preparation may cause clumping, poor dissolution, or reduced flocculation performance. Correct preparation ensures that PAM chains fully expand and work effectively in water or sludge treatment.

Preparation of PAM Solution

Materials Needed

- Polyacrylamide (PAM) dry powder

- Clean tap water or deionized water

- Mixing tank with agitator or mixer

Step-by-Step PAM Solution Preparation

1. Calculate the Required Amount of PAM

PAM solution concentration is usually 0.1%–0.2%.

- Example: To prepare 100 liters of 0.1% PAM solution, use 100 grams of PAM powder.

This concentration helps ensure good solubility and easy dosing.

2. Add Water to the Mixing Tank

Fill the tank with the required amount of water. Start stirring before adding PAM to create a stable vortex.

3. Slowly Add PAM Powder

Sprinkle the PAM powder slowly and evenly into the water.

⚠️ Do not dump the powder all at once. Slow addition prevents fish eyes and powder agglomeration.

4. Continue Stirring Until Fully Dissolved

- Mixing time: 30–60 minutes

- Stir gently to avoid breaking polymer chains

The solution should appear clear and uniform, without visible lumps.

5. Use the PAM Solution Promptly

Prepared PAM solutions are sensitive to hydrolysis.

- Best practice: use within 24 hours

- Avoid long-term storage to maintain performance

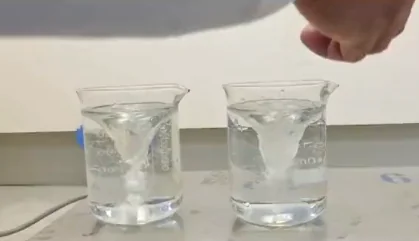

PAM Dosage Guidelines for Different Applications

The required PAM dosage depends on water quality, sludge characteristics, and treatment equipment.

1. PAM Dosage for Wastewater Treatment

- Typical dosage: 3–10 ppm (3–10 grams per ton of water)

PAM helps aggregate suspended solids and improve sedimentation or flotation efficiency.

🔍 Optimization Tip:

Jar testing is recommended. Factors such as pH, temperature, and SS concentration affect dosage.

2. PAM Dosage for Sludge Treatment

- Typical dosage: 10–50 ppm or higher

Sludge usually requires more PAM due to:

- High solids content

- High viscosity

- Fine particle size

Laboratory testing is strongly recommended to determine the exact dosage.

3. Mixing Time During Application

- Wastewater treatment: 10–30 seconds

- Sludge treatment: up to 2 minutes

⚠️ Avoid over-mixing. Excessive agitation can break flocs and reduce dewatering efficiency.

Key Considerations When Using PAM

Safety Precautions

- Wear gloves and safety goggles

- Avoid direct contact with dry powder

- Ensure good ventilation

Storage Conditions

- Store PAM powder in a cool, dry place

- Avoid moisture, heat, and direct sunlight

- Keep solutions in sealed containers

Performance Monitoring

- Monitor floc size and settling speed

- Adjust dosage based on real-time results

- Maintain stable treatment performance

Benefits of Proper PAM Preparation and Usage

- Improved treatment efficiency through strong floc formation

- Lower chemical costs by avoiding overdosing

- Better sludge dewatering, reducing disposal volume

- Easier regulatory compliance for discharge standards

Conclusion

Proper preparation and correct dosage of PAM are essential for successful water treatment and sludge dewatering. By following standard preparation procedures, using suitable concentrations, and optimizing dosage through testing, PAM can deliver stable, cost-effective, and efficient treatment results. Regular monitoring ensures long-term performance and compliance with environmental standards.