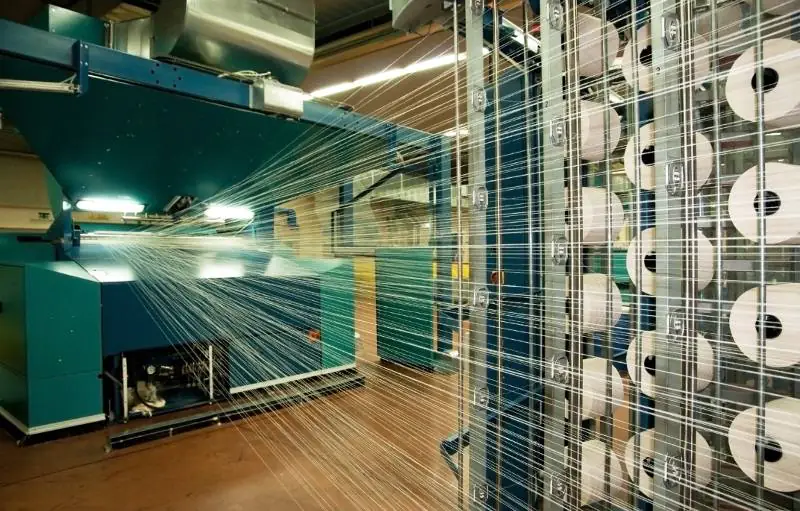

Improving Yarn Strength and Process Stability

In weaving and knitting operations, yarn breakage and abrasion are major causes of production loss. Sizing plays a critical role in protecting yarns during high-speed mechanical processing.

Polyacrylamide-based sizing agents are increasingly used in textile mills to improve yarn strength, surface smoothness, and processing stability.

Why PAM Is Used in Sizing Formulations

PAM forms a uniform and flexible polymer film on yarn surfaces, which:

- Reduces friction during weaving

- Improves tensile strength

- Enhances resistance to abrasion

Compared with starch-based sizing, PAM offers more consistent performance and easier control.

Operational Benefits for Textile Mills

- Fewer yarn breaks

- Higher loom efficiency

- Reduced machine downtime

- Improved fabric quality

Procurement perspective:

Stable sizing performance directly impacts production efficiency, not just chemical cost.

Selection Considerations

- Molecular weight suited to yarn type

- Film-forming ability

- Ease of desizing

- Compatibility with downstream dyeing

Conclusion

PAM-based sizing agents help textile plants improve productivity and fabric consistency. Proper selection ensures both performance and cost efficiency.