PolyDADMAC is a highly efficient cationic polymer coagulant. It is widely used in water and wastewater treatment, papermaking, textiles, oilfields, and mining due to its strong ability to remove suspended solids, improve clarification, and enhance filtration performance.

However, in real projects, PDADMAC performance varies greatly. Many users experience issues such as poor settling, overdosing, or unstable results. In most cases, the problem is not the product itself, but incorrect selection, dosage, or application method.

This article explains how PDADMAC works, where it is most effective, and how to use it safely and correctly, so you can achieve stable results and avoid unnecessary chemical waste.

What Is PolyDADMAC and Why It Is Used

PolyDADMAC is a water-soluble, linear polymer with strong positive charges. It works mainly through charge neutralization, making it especially effective for treating negatively charged colloids and fine particles.

Typical product form:

- Liquid solution (20%–40% active content)

- Occasionally powder form for special applications

Key characteristics:

- Effective pH range: 3–10

- Rapid coagulation

- Works well in both low- and high-turbidity water

- Often used as a primary coagulant, not just a coagulant aid

Key Properties of PDADMAC (Quick Reference)

- Appearance: Colorless to pale yellow viscous liquid

- Ionic type: Strong cationic

- Solubility: Completely water soluble

- pH (1% solution): 4–7

- Molecular weight: Adjustable (low to high, depending on application)

👉 These parameters directly affect performance, especially molecular weight and charge density.

Where PDADMAC Is Most Commonly Applied

PDADMAC is typically selected when fast clarification and compact flocs are required.

1. Water and Wastewater Treatment

- Municipal drinking water clarification

- Industrial wastewater with high colloidal content

- Sludge conditioning and dewatering

Why PDADMAC?

It provides rapid charge neutralization and reduces turbidity quickly, especially where inorganic coagulants alone are insufficient.

2. Pulp and Paper Industry

- Retention and drainage improvement

- Fixation of anionic trash

- Improved paper strength and formation

3. Textile and Dyeing Wastewater

- Dye fixing agent

- Color removal in dye effluent

- Improves color fastness and reduces dye loss

4. Oilfield and Mining Water

- Clarification of produced water

- Sludge settling

- Emulsion breaking

Safe Handling of PDADMAC (Operational Reality)

PDADMAC is considered low-toxicity, but improper handling can still cause safety or operational issues.

Personal Protection

- Chemical-resistant gloves

- Safety goggles

- Protective clothing

- Respiratory protection if aerosols are present

Storage Guidelines

- Store in a cool, dry, ventilated area

- Keep containers tightly sealed

- Avoid freezing and long-term exposure to high temperatures

First Aid (On-Site Reference)

- Skin: Rinse with water, remove contaminated clothing

- Eyes: Flush for at least 15 minutes

- Inhalation: Move to fresh air

- Ingestion: Do not induce vomiting, seek medical advice

Recommended PDADMAC Dosage (Typical Ranges)

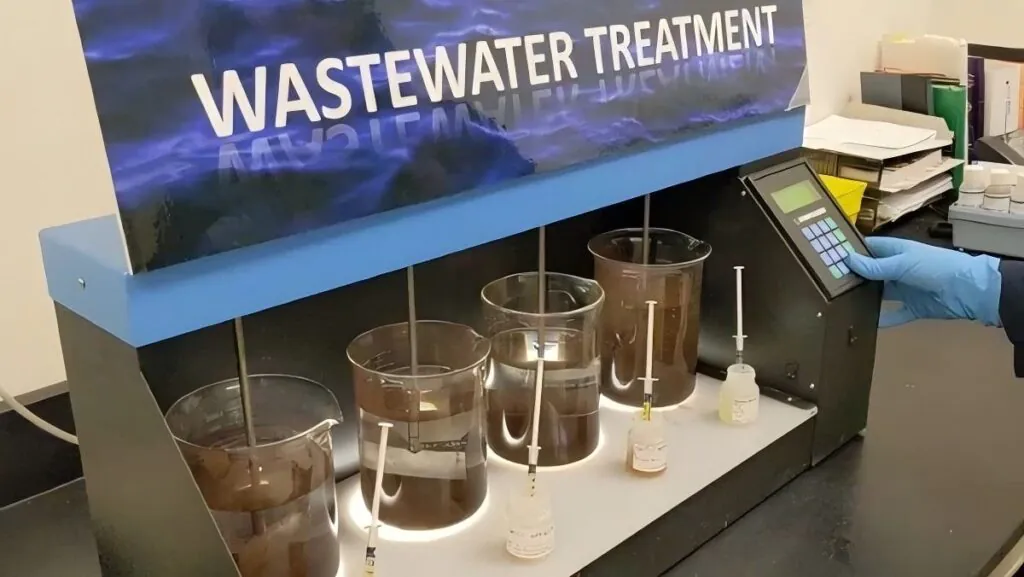

⚠️ There is no universal dosage. Jar testing is essential.

| Application | Typical Dosage |

|---|---|

| Drinking water coagulation | 1–10 ppm |

| Industrial wastewater | 10–50 ppm |

| Textile dye fixing | 0.5–2.0 g/L |

| Papermaking retention | 0.1–0.5% of dry fiber |

| Sludge dewatering | 20–100 ppm (DS basis) |

👉 Overdosing may cause restabilization and worsen effluent quality.

How to Apply PDADMAC for Best Results

Correct application is often more important than dosage.

1. Dilution

- Dilute liquid PDADMAC 1:5 to 1:20 with clean water

- Ensures even distribution and avoids local overdosing

2. Dosing Sequence

- Add PDADMAC first

- Then add flocculants such as PAM if required

3. Mixing

- Ensure sufficient rapid mixing for charge neutralization

- Follow with gentle mixing for floc growth

4. Monitoring

- Observe floc size and settling speed

- Adjust dosage based on turbidity and sludge volume

Environmental Considerations

PDADMAC is safe when used correctly, but excessive discharge may affect aquatic organisms due to its strong cationic nature.

✔ Follow local discharge regulations

✔ Avoid uncontrolled release

✔ Optimize dosage to minimize residual polymer

Why PDADMAC Selection Requires Technical Support

Many users assume PDADMAC is a “plug-and-play” chemical. In reality, performance depends on:

- Molecular weight selection

- Charge density

- Water chemistry

- Interaction with other chemicals

👉 Incorrect selection often leads to higher costs, not better results.

How We Support Your PDADMAC Application

As a professional water treatment chemical supplier, we provide:

- Multiple PDADMAC grades for different applications

- Technical guidance on selection and dosage

- Jar test support and troubleshooting

- Flexible packaging and stable supply

If you are facing unstable clarification, high chemical consumption, or uncertain PDADMAC selection, technical matching is the key to solving the problem.

📩 Contact our technical team to discuss your water conditions and application needs. The right PDADMAC solution starts with correct selection—not trial and error.