Polyacrylamide (PAM) is one of the most widely used water treatment chemicals in industrial processes.

It is commonly applied in wastewater treatment, petroleum, papermaking, textiles, and many other industries.

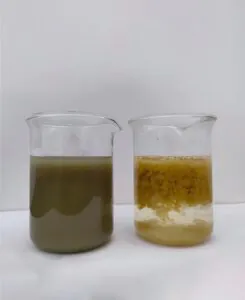

Its main function is flocculation. PAM helps small suspended particles combine into larger flocs, making solid–liquid separation easier and more efficient.

How to Use Polyacrylamide Correctly

Polyacrylamide must be fully dissolved in water before use.

The prepared solution is then added to wastewater to promote flocculation and sedimentation.

Before large-scale use, proper product selection is critical.

Key Factors for Selecting the Right Polyacrylamide

Polyacrylamide selection should be based on multiple site conditions, including:

-

Wastewater pH value

-

Wastewater temperature

-

Type and concentration of impurities

-

Sludge dewatering equipment (filter press type)

In practice, the correct process is:

-

Laboratory jar test

-

Pilot test

-

On-site machine operation

During operation, focus on:

-

Moisture content of the sludge cake

-

Clarity of the supernatant

Is Bigger Floc Always Better?

Many users believe that larger flocs mean better performance.

This is a common misunderstanding.

The ideal floc size depends on the type of sludge dewatering machine.

Floc Size vs. Sludge Dewatering Equipment

Plate & frame filter press / belt filter press

-

Flocs do not need to be too large

-

Oversized flocs trap excess water

-

This leads to higher sludge cake moisture

-

Filtration efficiency may decrease

Screw press / centrifuge

-

Flocs should be large and compact

-

Strong flocs resist breakage at high speed

-

Better for stable and efficient sludge dewatering

Final Conclusion

Bigger flocs are not always better.

The correct polyacrylamide and floc size must be selected based on:

-

Actual wastewater conditions

-

Sludge characteristics

-

Dewatering equipment used on site

Only by matching chemicals + process + equipment can you achieve the best sludge dewatering results.

Article Summary

Polyacrylamide plays a key role in industrial water treatment, but floc size must match the dewatering equipment.

Choosing the right PAM through testing ensures lower sludge moisture and better treatment efficiency.