Why PAM Matters in Completion Fluids

Completion fluids play a critical role in protecting reservoir integrity during well completion and workover operations. Unlike drilling fluids, completion fluids must balance operational performance and formation protection.

Polyacrylamide (PAM) is widely used in completion fluids because it offers controlled viscosity, effective fluid-loss reduction, and solid suspension with low solids content. When properly selected, PAM helps reduce formation damage while maintaining stable fluid performance.

From a purchasing and engineering perspective, the real value of PAM lies in choosing the right grade, not simply adding polymer to increase viscosity.

Key Functions of PAM in Completion Operations

1. Fluid Loss Control with Minimal Formation Damage

During completion, excessive fluid invasion can lead to:

- Clay swelling

- Fines migration

- Permanent permeability reduction

Low-residue PAM forms a thin, temporary filter layer that reduces fluid loss while allowing efficient cleanup during flowback.

Procurement insight:

Lower-residue PAM grades may have higher unit prices, but they significantly reduce long-term reservoir damage risks.

2. Suspension of Solids and Bridging Materials

Completion fluids often contain:

- Bridging agents

- Fine solids

- Temporary weighting materials

PAM improves low-shear viscosity, keeping particles suspended during placement without excessively increasing pumping pressure.

3. Clay and Fines Stabilization

Many sandstone reservoirs contain water-sensitive clays. Selected PAM grades can:

- Bind mobile fines

- Reduce clay dispersion

- Improve wellbore stability during perforation and stimulation

This function is especially important in high-permeability and clay-rich formations.

How to Select the Right PAM for Completion Fluids

Selecting PAM for completion fluids focuses on formation protection, not maximum thickening.

Key Selection Criteria

- Low molecular residue

- Controlled charge density

- Brine compatibility (NaCl, CaCl₂, ZnBr₂)

- Proven cleanup performance

| PAM Type | Typical Application |

|---|---|

| Low-MW Anionic PAM | Fluid loss control |

| Nonionic PAM | High-salinity completion brines |

| Low-charge Cationic PAM | Clay stabilization |

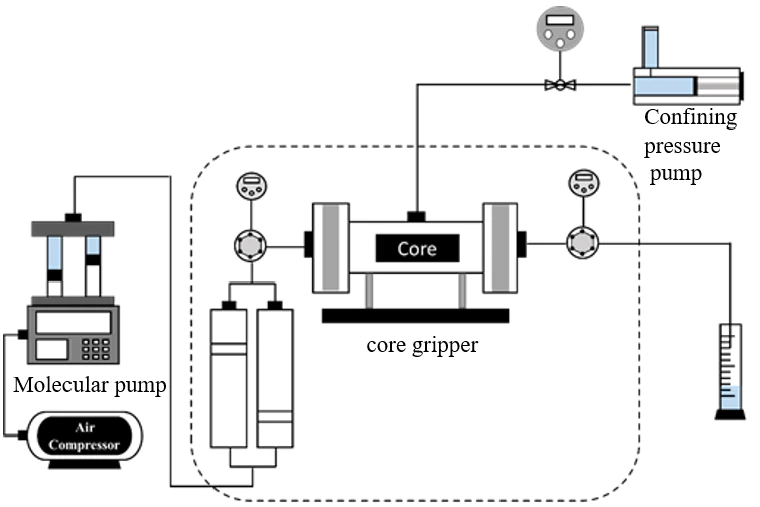

Laboratory Testing Before Field Application

Before approving any PAM for completion fluids, laboratory validation is essential.

Recommended tests include:

- Brine compatibility tests

- Core-flow damage and cleanup tests

- Filter cake thickness evaluation

- Thermal aging at downhole temperatures

⚠️ A PAM grade suitable for drilling fluids may still cause formation damage if used in completion fluids without proper testing.

Field Mixing and Dosing Guidelines

Typical Dosage Range

- 0.5–5 g/L in working completion fluids

- Commonly added as 0.1–0.5% pre-diluted solution

Always confirm dosage through lab testing.

Mixing Best Practices

- Use clean water or compatible brine

- Pre-dilute PAM before injection

- Avoid excessive shear after hydration

- Maintain consistent circulation

Poor hydration can lead to viscosity spikes and uneven filter cake formation.

Common Problems and Practical Solutions

| Problem | Likely Cause | Solution |

|---|---|---|

| Poor flowback | High residue polymer | Use low-residue PAM |

| High pumping pressure | Overdosing | Reduce concentration |

| Polymer precipitation | Brine incompatibility | Switch to nonionic PAM |

| Formation damage | Excess adsorption | Validate with core tests |

Most failures are caused by incorrect selection, not PAM itself.

Environmental and Safety Considerations

- Use certified low-acrylamide PAM grades

- Follow PPE guidelines for handling powders and solutions

- Manage spent fluids according to local regulations

- Ensure supplier provides MSDS and monomer specifications

Conclusion: PAM in Completion Fluids Is a Strategic Choice

Polyacrylamide (PAM) is more than a viscosity modifier in completion fluids. It is a reservoir protection tool that directly impacts long-term well productivity.

By selecting the correct PAM grade, validating performance through laboratory testing, and applying disciplined field practices, operators can achieve stable completion operations while minimizing formation damage.

For buyers and engineers, working with experienced suppliers who understand brine chemistry, reservoir sensitivity, and cleanup behavior is essential for successful completion-fluid design.