In anaerobic wastewater treatment, an abnormal increase in volatile fatty acids (VFA) is a common operational problem.

Under normal conditions, VFA is consumed by microorganisms during the methanogenesis stage.

However, when VFA accumulates excessively, it can:

- Break system balance

- Cause reactor acidification

- Reduce treatment efficiency

- Even lead to complete system failure

This article analyzes the problem from two aspects:

- Common causes of VFA increase

- Potential risks of VFA accumulation

I. Five Common Causes of VFA Increase

1. High Organic Load in Influent

When the influent organic load is too high, acid-producing bacteria grow rapidly.

Methanogens cannot consume VFA at the same rate, resulting in continuous VFA accumulation.

This situation is common during:

- Sudden load increase

- Start-up phase

- Shock loading events

2. Low Influent Temperature

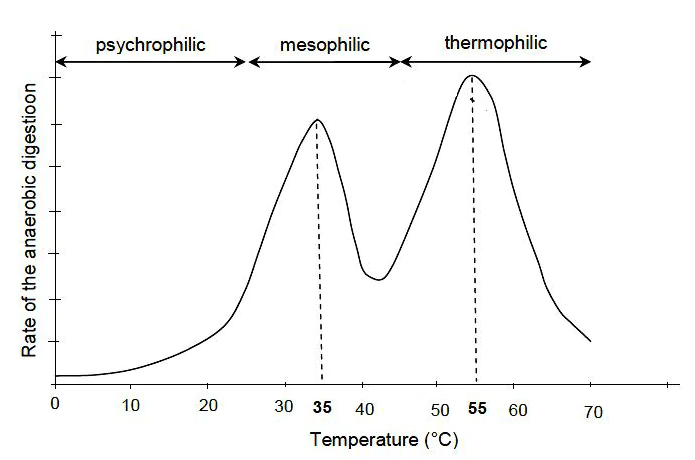

The optimal operating temperature for most anaerobic systems is around 35°C.

A sudden temperature drop significantly reduces methanogen activity, slowing VFA conversion and causing accumulation.

3. Low pH or Low Alkalinity

When influent pH falls below 6.5, system buffering capacity becomes insufficient.

Accumulated VFA further lowers pH, which:

- Inhibits methanogens

- Accelerates acidification

- Creates a vicious cycle

4. High Sulfate Concentration

In sulfate-rich wastewater, sulfate reduction produces sulfide, which is toxic to methanogens.

This inhibition reduces VFA removal efficiency and leads to higher residual VFA levels.

5. Toxic, Harmful, or Non-Biodegradable Substances

Substances such as:

- Heavy metals

- Organic toxins

- Refractory compounds

can damage methanogens, slow metabolic reactions, and directly cause VFA buildup.

II. Potential Risks of VFA Accumulatio

Excessive VFA poses serious risks to anaerobic systems, including:

- Inhibition of methanogen activity

- Reduced effluent quality and stability

- Rapid pH decline and reactor acidification

- Eventual anaerobic system failure or collapse

Early detection and control are critical to prevent irreversible damage.

Conclusion

Monitoring and controlling VFA concentration is essential for stable anaerobic operation.

Operational problems can be avoided by:

- Adjusting influent organic load

- Maintaining stable temperature

- Controlling pH and alkalinity

- Reducing sulfate and toxic substances

Timely process optimization helps maintain system balance and ensures long-term treatment performance.