A nonionic flocculant, commonly abbreviated as NPAM, is a linear water-soluble polymer. Its molecular weight typically ranges from 5 to 12 million. In solid form, it appears as a white powder, while in liquid form it is a colorless, viscous colloid.

Nonionic polyacrylamide dissolves easily in water but is hardly soluble in organic solvents. It should be dissolved at normal temperature, as the polymer structure may decompose when the temperature exceeds 150 °C. NPAM is classified as non-dangerous, non-toxic, and non-corrosive, making it safe for industrial handling and application.

In solid form, NPAM is hygroscopic and exhibits excellent flocculation, adhesion, drag reduction, thickening performance, and long-term stability.

Flocculation Characteristics of Nonionic Polyacrylamide

Unlike anionic or cationic polyacrylamide, nonionic flocculants do not contain ionic functional groups. Because of this, their flocculation performance is less affected by pH value and salt concentration.

Under acidic conditions, nonionic polyacrylamide often performs better than anionic polyacrylamide. The formed flocs are stronger, more compact, and more resistant to shear forces. This makes NPAM especially suitable for wastewater systems with unstable water chemistry or acidic characteristics.

Applications of Nonionic Flocculant

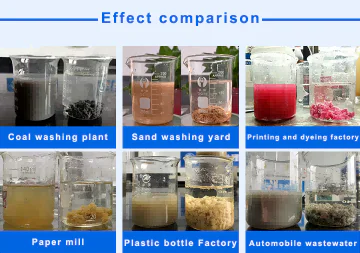

Nonionic polyacrylamide is widely used in solid–liquid separation processes, including sedimentation, clarification, thickening, concentration, and sludge dewatering.

Municipal and Industrial Wastewater Treatment

NPAM is suitable for:

- Municipal sewage

- Papermaking wastewater

- Food processing wastewater

- Petrochemical wastewater

- Metallurgical wastewater

- Dyeing and printing wastewater

- Sugar industry wastewater

- Various industrial wastewater systems

When wastewater is acidic, nonionic polyacrylamide is often used together with polyaluminum chloride (PAC) or other inorganic flocculants. This combination provides fast settling speed and stable treatment performance.

Applications in the Paper Industry

In the paper industry, nonionic polyacrylamide can be used as:

- Paper dry strength agent

- Retention aid

- Filtration aid

It improves fiber retention, drainage efficiency, and overall paper quality.

Mining and Mineral Processing Applications

NPAM is commonly applied in:

- Mine wastewater clarification

- Coal washing wastewater treatment

- Tailings sedimentation and filtration

- Coal slime centrifugal separation

In these processes, nonionic polyacrylamide can increase coal recovery rate, improve filtration speed, and enhance solid–liquid separation efficiency.

Other Industrial Applications

- Textile industry: Used as a sizing additive to improve adhesion, penetration, antistatic performance, and desizing efficiency while reducing sizing consumption.

- Construction industry: Acts as a chemical grouting agent when combined with methylene bisacrylamide, strengthening soil and improving structural stability in dams, tunnels, and foundations.

- Phosphoric acid purification: Helps separate gypsum during the wet phosphoric acid process.

- Drinking water treatment: Used as a flocculant in tap water treatment plants.

- Soil water retention: Applied as a soil water-retaining agent for sand fixation, slope greening, and dust control.

- Oilfield applications: Used as an oil plugging agent when combined with lignocellulose and other additives.

Summary

Nonionic polyacrylamide is a versatile and stable flocculant, especially suitable for acidic wastewater and complex industrial conditions. Its low sensitivity to pH and salts, strong floc strength, and wide application range make it an important material in water treatment, mining, papermaking, construction, and oilfield industries.

Choosing the correct dosage and combining NPAM with suitable inorganic flocculants can significantly improve treatment efficiency and reduce operating costs.