Recently, our technical team successfully completed the commissioning and system upgrade of a wastewater treatment system at a sand washing plant.

This project focused on two key aspects:

- On-site commissioning process and problem analysis

- Technical solutions and final optimization results

Through targeted improvements, the system achieved more stable operation, better effluent quality, and higher sludge dewatering efficiency.

Commissioning Process and On-Site Problems

After the project began, our technicians arrived at the site immediately. They carefully reviewed the existing treatment process, equipment configuration, and chemical reactions with the wastewater. Several key problems were identified during on-site inspection.

1. Small Dosing Tank Capacity Affects Continuous Operation

The customer used two small 1-ton dosing tanks alternately.

When wastewater flow increased and chemical demand rose:

- Tank switching could not keep up

- Chemical dissolution was incomplete

- Reaction efficiency dropped

This directly affected system continuity and stability.

2. Unreasonable Dosing Method

The site relied on gravity dosing using bottom pipes and valves.

As the liquid level decreased:

- Pressure dropped

- Flow rate slowed

- Actual chemical dosage became insufficient

This resulted in weak reactions and unstable treatment performance.

3. Poor Mixing of Chemicals and Wastewater

The flow channel had very few baffles, leading to poor mixing.

As a result:

- Chemicals did not fully contact wastewater

- Flocculation efficiency was low

- Chemical consumption increased unnecessarily

4. High Wastewater Concentration Requires Higher Dosage

The wastewater contained a high sludge concentration.

When chemical dosage was too low:

- Flocs formed poorly

- Reaction strength was insufficient

- Solid–liquid separation performance declined

5. Low Sludge Dewatering Efficiency

Sludge separation in the thickening tank was weak.

Due to insufficient flocculation:

- Sludge structure was loose

- Plate-and-frame filter press dewatering efficiency was low

- Final sludge output did not meet expectations

Solutions and Commissioning Results

Based on on-site conditions, our team worked closely with the customer and developed a practical improvement plan in four key areas.

1. Upgrade Dosing Equipment

We recommended:

- Using larger-capacity dosing tanks, or

- Pre-dissolving chemicals before tank switching

This ensured continuous chemical supply and stable system operation.

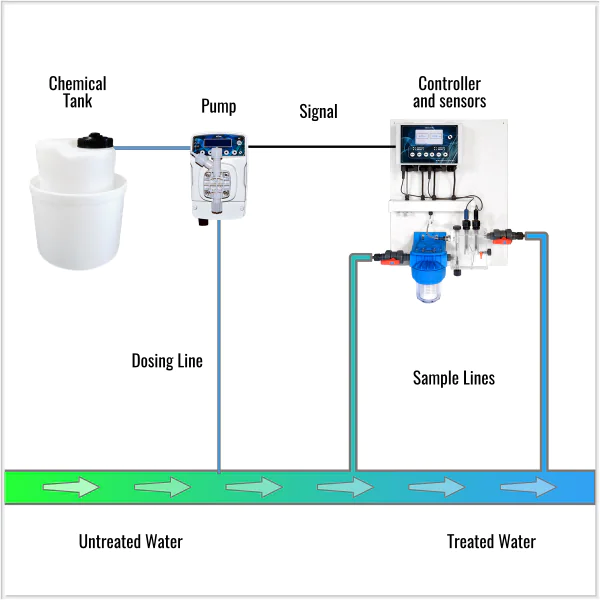

2. Improve the Dosing Method

Gravity dosing was replaced with metering pumps.

This change provided:

- Accurate and stable dosing

- Better control of chemical addition

- Improved reaction efficiency and chemical utilization

3. Modify Flow Channel Structure

Additional baffles were installed in the flow channel to:

- Increase turbulence

- Improve mixing between chemicals and wastewater

- Enhance flocculation performance

This ensured more complete chemical reactions.

4. Adjust Chemical Dosage Based on Sludge Concentration

Chemical dosage was optimized according to actual sludge content.

After valve adjustment and dosage increase:

- Clear and compact flocs formed

- Sludge–water separation improved significantly

- Dewatering performance of the filter press increased

Final Results and Customer Feedback

After commissioning and optimization:

- The system operates more stably and efficiently

- Chemical reactions are complete

- Effluent quality has improved significantly

- Sludge dewatering efficiency is much higher

The customer highly recognized our technical service and practical solutions.

We will continue to follow our service philosophy of “Professional, Efficient, Precise” , providing customized wastewater treatment solutions to support green production and compliant discharge.