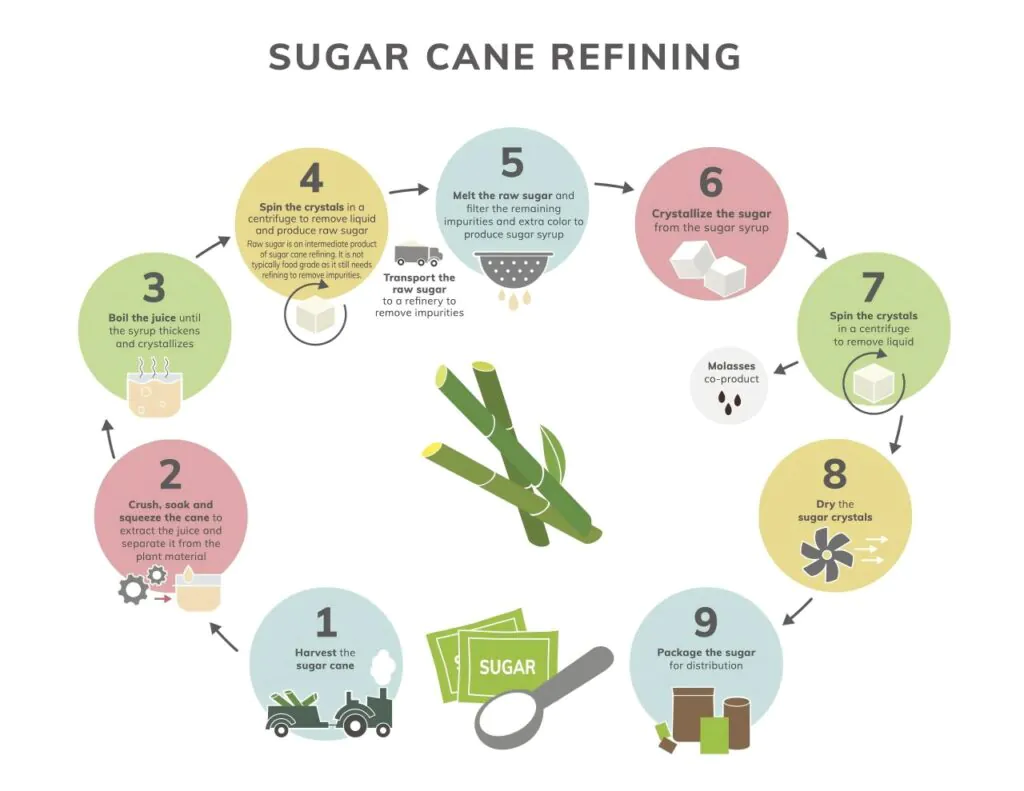

Sugar is a core raw material widely used in beverages, confectionery, bakery products, processed foods, and daily cooking. Global sugar production mainly relies on sugarcane (about 80%) and sugar beet (about 20%). Major sugarcane-producing countries include Brazil, India, China, Thailand, and Pakistan, while sugar beet production is concentrated in France, the United States, Germany, Russia, and Turkey.

During sugar production, large volumes of sugar juice and process wastewater are generated. Both must be properly treated to ensure product quality, process stability, and environmental compliance. Among all treatment steps, clarification plays a decisive role.

Over the past decade, Polyaluminium Chloride (PAC) has become one of the most widely used coagulants in sugar factories worldwide. Thanks to its high efficiency, strong adaptability, and stable performance, PAC is now a key solution for juice purification and wastewater treatment in the sugar industry.

Role of PAC in the Sugar Industry

Polyaluminium chloride is an inorganic polymer coagulant with high charge density and strong adsorption capability. It effectively destabilizes suspended solids, colloids, and dissolved organic matter.

In sugar factories, PAC is commonly used for:

- Clarification of sugarcane juice and beet juice

- Removal of color and turbidity

- Enhancement of sedimentation and filtration

- Pretreatment and treatment of sugar industry wastewater

Compared with traditional coagulants such as aluminum sulfate or lime, PAC operates efficiently across a wider pH range, produces less sludge, and offers faster floc formation.

PAC for Sugar Juice Clarification

Raw sugar juice contains many impurities, including plant fibers, suspended solids, colloids, proteins, pigments, soil particles, and inorganic matter. If not removed effectively, these impurities negatively affect:

- Juice purity

- Crystallization efficiency

- Sugar color and quality

- Scaling in evaporators

PAC is widely used to remove these contaminants through clarification.

How PAC Works in Juice Purification

PAC improves juice quality through several mechanisms:

- Charge neutralization

Positively charged PAC neutralizes negatively charged colloids and fine particles, reducing their stability. - Floc formation and sedimentation

Impurities such as proteins, pigments, and sand particles are captured into larger flocs that settle rapidly. - Color adsorption

PAC adsorbs color-causing compounds, resulting in lighter syrup and improved final sugar appearance.

Advantages of PAC in Juice Clarification

- Improved juice clarity and color reduction

- Faster settling and shorter clarification time

- Lower turbidity in clarified juice

- Reduced scaling in heaters and evaporators

- Improved crystallization efficiency and sugar yield

- Lower chemical consumption than traditional coagulants

- Reduced sludge volume and easier sludge handling

Overall, PAC enhances both process efficiency and final sugar quality.

Recommended PAC Dosage for Juice Clarification

Actual dosage depends on juice quality, raw material type, and impurity level.

Typical reference ranges:

- Raw sugarcane juice: 20–50 mg/L

- Combined with flocculants: 10–30 mg/L

- High-impurity or rainy-season juice: 40–80 mg/L

Laboratory jar tests are recommended to determine the optimal dosage under specific operating conditions.

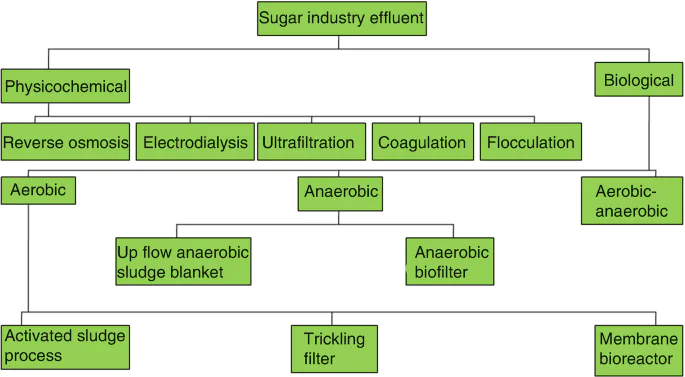

PAC in Sugar Industry Wastewater Treatment

Untreated sugar industry wastewater can cause serious environmental pollution and odor problems. Wastewater mainly comes from:

- Juice extraction and washing

- Clarification and filtration processes

- Boiler blowdown

- Equipment cleaning

- Condensate and cooling water

Characteristics of Sugar Industry Wastewater

Sugar industry wastewater typically features:

- High COD and BOD

- High suspended solids

- Dark color

- Low pH

- High dissolved organic and inorganic content

- Odor generation

These characteristics make coagulation and pretreatment essential.

Working Principle of PAC in Wastewater Treatment

PAC improves wastewater quality through:

- Coagulation and sedimentation

Destabilizes colloids and suspended solids to form dense flocs. - COD and BOD reduction

Removes dissolved organic compounds responsible for high oxygen demand. - Decolorization

Adsorbs pigments and chromogenic substances. - Sludge volume reduction

Produces compact sludge that is easier to dewater and dispose of.

Benefits of Using PAC in Sugar Wastewater Management

- COD removal efficiency of 60–85%, depending on conditions

- Significant reduction in turbidity and TSS

- Faster sedimentation in clarifiers

- Lower sludge production compared with alum or iron salts

- Stable performance in pH range 5–9

- Reduced need for pH adjustment chemicals

- Improved performance of downstream biological treatment

These advantages make PAC a cost-effective and reliable choice for sugar factories.

Recommended PAC Dosage for Wastewater Treatment

Typical dosage guidelines:

- General wastewater: 30–150 mg/L

- High-COD wastewater: 100–200 mg/L

- Combined with PAM: 20–50 mg/L

Proper dosage avoids overdosing while ensuring effective clarification.

PAC Dosing Points and Synergistic Use

PAC Addition Points

- Pretreatment stage: Primary dosing point for turbidity and colloid removal

- Before flocculation and sedimentation: Combined use with PAM improves floc strength and settling

Synergistic Chemical Use

- PAC + PAM for stronger flocs

- Decolorizing agents for high-color wastewater

- Optimal pH: 6.5–7.5, adjusted with lime if necessary

Summary

Polyaluminium chloride (PAC) has become a core chemical solution in the modern sugar industry. Its strong coagulation ability, wide pH adaptability, fast settling speed, and low sludge production make it highly effective for both sugar juice clarification and wastewater treatment.

By optimizing PAC dosage and combining it with auxiliary flocculants such as PAM, sugar factories can achieve stable clarification performance, higher sugar yield, lower operating costs, and consistent environmental compliance.