In modern wastewater treatment, polyaluminum chloride (PAC) and polyacrylamide (PAM) are often used together to improve flocculation and solid–liquid separation. PAC acts as a coagulant that destabilizes suspended particles, while PAM works as a flocculant that bridges small particles into larger, heavier flocs. When the dosage of these two chemicals is well matched, the treatment process becomes faster, more stable, and more cost-effective.

PAC has strong chemical stability at room temperature and works effectively within a wide pH range. After dosing, it reacts quickly with impurities in water and forms visible alum flocs. These flocs can capture pollutants such as phosphorus, ammonia nitrogen, COD, BOD, and even some heavy metal ions. This happens through charge neutralization and adsorption, allowing contaminants to gather into larger particles that are easier to settle and filter.

PAM: The Key to Stronger and Faster Flocs

While PAC starts the coagulation process, PAM is the key material that strengthens flocs and improves settling speed. As a polymer flocculant, PAM can be adjusted in molecular weight and ionic type to suit different wastewater conditions. Proper PAM dosage makes flocs denser and more compact, which leads to clearer supernatant water and better sludge dewatering performance. However, if PAM is under-dosed or overdosed, flocs may become loose or sticky, and the water can remain turbid.

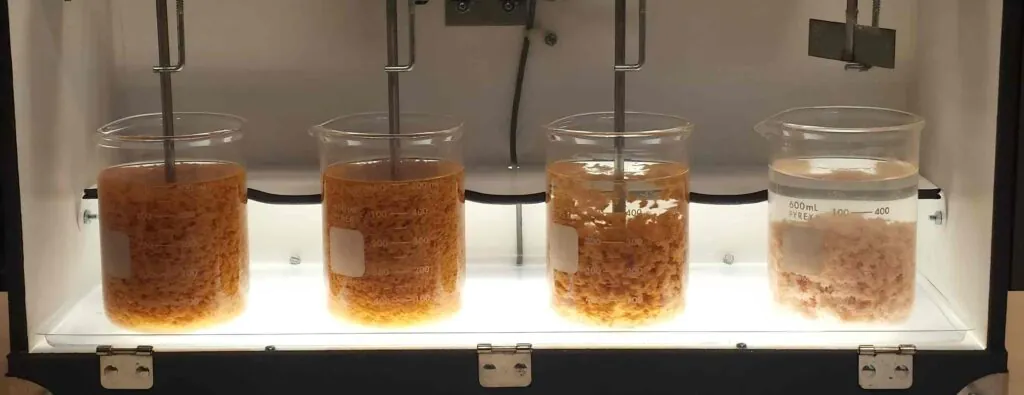

How to Judge PAC and PAM Dosage by Observing Flocs

In daily plant operation, floc condition is one of the most direct indicators of chemical performance. If flocs appear small but evenly distributed, it often means that the balance between PAC and PAM is not ideal. In this case, slightly increasing PAC dosage may help improve coagulation.

If large flocs form and settle quickly but the supernatant remains turbid, PAC may be insufficient or the PAM type may not be suitable. Operators can try increasing PAC while keeping PAM dosage stable and then observe the changes. When flocs look thick and heavy but water clarity is still poor, a small increase in PAM may improve bridging. If sediment is very fine and difficult to settle, PAM dosage may be too low and should be increased gradually.

Jar testing is an important tool for confirming dosage. During the jar test, if sticky scum attaches to the beaker wall, it usually indicates excessive PAM. Reducing PAM dosage can help restore proper floc structure. When the supernatant becomes very clear regardless of floc size, it usually means the PAC and PAM ratio is close to optimal.

Why Proper Dosing Matters

Achieving the best flocculation effect depends on careful control of both PAC and PAM. Water quality, suspended solids concentration, and treatment targets all influence the required dosage. Blindly increasing chemical usage does not improve results and only raises costs. A balanced dosing plan improves treatment efficiency, reduces sludge volume, and lowers overall operating expenses.

In practical applications, chemical storage, preparation, and feeding methods also affect performance. Using fresh solutions, accurate dosing equipment, and suitable mixing conditions helps both PAC and PAM perform at their best.

Get Professional Support for Chemical Selection

Every wastewater system is different, and choosing the right PAC grade and PAM model is just as important as dosage control. Working with an experienced supplier can help you conduct jar tests, analyze water quality, and recommend suitable products. This not only ensures stable effluent quality but also reduces long-term chemical costs.

If you need support in selecting PAC and PAM or optimizing your dosing strategy, our technical team can provide product recommendations, sample testing, and application guidance based on your water conditions. Feel free to contact us for more details.