As cities grow and environmental standards become stricter, wastewater treatment plants must find solutions that are both effective and sustainable. Poly Aluminum Chloride (PAC) has become a preferred coagulant in municipal wastewater treatment because of its high efficiency, flexibility, and lower environmental impact compared to traditional chemicals.

Introduction to PAC and Its Role in Water Treatment

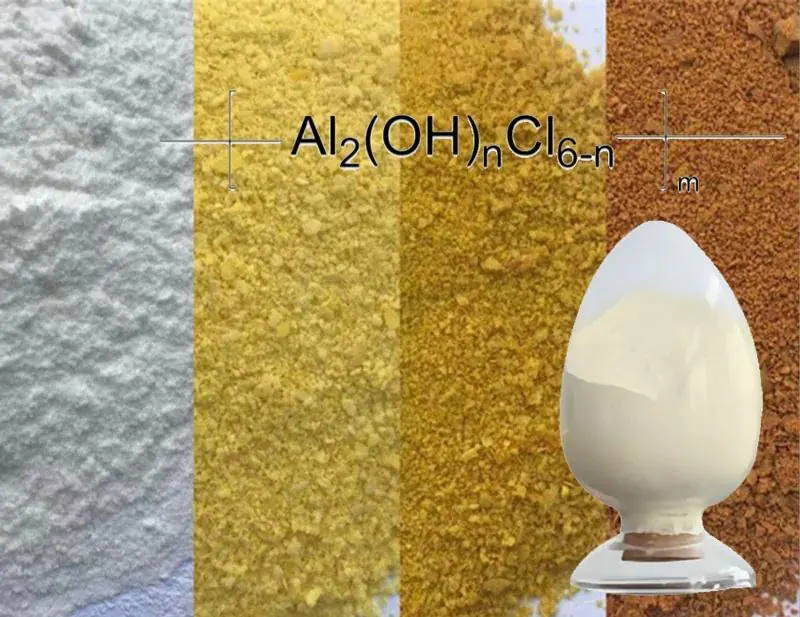

Poly Aluminum Chloride, commonly known as PAC, is widely used as a coagulant in water and wastewater treatment. Its main function is to destabilize suspended particles and help them form larger flocs that can be removed easily through sedimentation or filtration.

Compared with traditional coagulants such as alum (aluminum sulfate) and ferric chloride, PAC wastewater treatment systems often achieve better results with lower chemical dosage and reduced sludge production. This makes PAC both economically and operationally attractive for municipal facilities.

PAC’s Versatility in Different Water Conditions

Strong Performance in Changing Water Quality

Municipal wastewater quality can vary greatly due to seasonal changes, rainfall, and industrial discharge. One major advantage of poly aluminum chloride PAC is its ability to perform well across a wide range of pH levels, temperatures, and turbidity conditions.

During rainy seasons, for example, incoming water often has higher turbidity. PAC can quickly form dense flocs even under these unstable conditions. In colder climates, PAC also maintains good coagulation performance, where some traditional coagulants become less effective.

This adaptability helps treatment plants maintain stable operation and consistent effluent quality throughout the year.

Growing Global Adoption of PAC

Why Municipalities Are Choosing PAC

More municipalities in Europe, North America, and Asia are switching to PAC for wastewater treatment. The reasons are clear: better treatment performance, lower operating costs, and improved environmental outcomes.

As urban populations increase, treatment plants must handle larger volumes of wastewater without dramatically increasing costs. PAC supports this goal by improving coagulation efficiency while reducing chemical consumption and sludge handling requirements.

Economic Advantages: Lower Dosage and Less Sludge

Reduced Chemical Consumption

One key reason municipalities prefer PAC vs alum is dosage efficiency. PAC often requires 20–30% less product to achieve the same or better turbidity and organic matter removal. This directly reduces chemical purchasing costs.

Sludge Reduction and Disposal Savings

Traditional coagulants can generate large volumes of sludge, which must be thickened, dewatered, transported, and disposed of. PAC typically produces significantly less sludge—sometimes up to 50% less—depending on water quality and process design.

Lower sludge volume means lower disposal costs and less pressure on landfills or incineration facilities. This makes PAC wastewater treatment both economically and environmentally beneficial.

PAC as an Environmentally Friendly Coagulant

Sustainability is a growing priority in municipal water management. PAC supports greener operations in several ways:

- Reduced sludge production lowers solid waste output

- Lower dosage reduces chemical transport and storage needs

- Efficient coagulation can reduce overall energy use in downstream processes

In addition, PAC does not introduce significant levels of harmful byproducts when used correctly. This makes it a safer choice for long-term environmental protection compared to some older treatment chemicals.

Performance in Large-Scale Municipal Systems

Municipal treatment plants must operate reliably under changing loads and weather conditions. PAC’s strong coagulation ability makes it suitable for:

- Primary clarification

- Secondary treatment support

- Tertiary polishing processes

It is effective in removing suspended solids, organic matter, phosphorus, and some heavy metals. Because of its stable performance, PAC helps municipalities meet discharge standards even during peak flow periods.

Future Trends: PAC and Sustainable Water Management

As environmental regulations tighten, treatment plants are under pressure to improve efficiency while lowering environmental impact. Poly aluminum chloride PAC fits well with this trend.

For developing regions, PAC offers an effective solution without requiring major infrastructure upgrades. For advanced facilities, PAC helps optimize performance and reduce operational costs. Its flexibility makes it a key part of the future of municipal water treatment chemicals.

Conclusion

PAC has become a vital solution in modern municipal wastewater treatment. Its ability to work in varied water conditions, reduce chemical dosage, and minimize sludge production makes it superior to many traditional coagulants.

By choosing PAC for wastewater treatment, municipalities can achieve better water quality, lower operating costs, and a smaller environmental footprint. As sustainability becomes central to water management, PAC will continue to play an increasingly important role in shaping the future of wastewater treatment worldwide.