Polyacrylamide (PAM) is a key flocculant used in wastewater treatment. It helps remove particles from water in industries like mining, drilling, paper-making, and municipal sewage. However, many users feel confused when choosing the correct type of PAM flocculant. This article explains the three main types—anionic, cationic, and nonionic PAM—and how to choose the best one for your needs.

Types of Polyacrylamide (PAM) and Their Features

There are three types of PAM flocculants:

🔹 Anionic PAM (APAM)

✅ Best for: Wastewater with large solid particles or high concentration, such as industrial wastewater, mining, coal washing, and drilling slurry.

✅ How to choose:

- For general flocculation and sedimentation, use PAM with 8 to 18 million molecular weight. This is enough for most needs.

- For high concentration sludge (like drilling or construction slurry), use higher molecular weight PAM. It improves floc formation and speeds up settling.

- Higher molecular weight = thicker solution and better for high solids wastewater.

- Higher hydrolysis degree = faster dissolving, but also more expensive.

🔹 Cationic PAM (CPAM)

✅ Best for: Sludge dewatering, municipal sewage, paper-making wastewater, and organic sludge.

✅ How to choose:

- Cationic PAM is chosen by charge density (10% to 80%).

- Higher charge = stronger attraction to particles, but not always better. Match it to your sludge type.

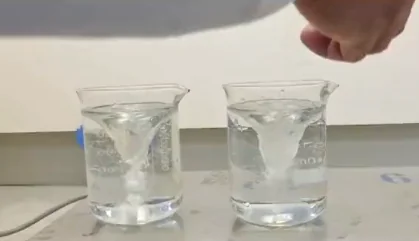

- Always do a small test before full use. Sludge types vary a lot.

- For basic use, start testing with medium charge (20%–40%).

- For high organic sludge, use higher charge (50%+).

🔹 Nonionic PAM (NPAM)

✅ Best for: Acidic wastewater, mining water, and special conditions.

✅ Features:

- Low charge, small molecular weight.

- Good for low turbidity water and acidic environments.

✅ How to choose:

- For acidic wastewater, nonionic PAM is better. It works when other PAM types fail due to pH.

- For mining wastewater with heavy metal ions, NPAM helps with better separation.

- NPAM is less common. Most cases still use anionic or cationic PAM.

Tips for Choosing and Using PAM Flocculants

💡 Anionic PAM is mostly used for sedimentation at the beginning stage. It works well with coagulants like PAC or iron salts.

💡 Cationic PAM is mainly used for sludge dewatering. Always do a small test first to find the best charge level.

💡 Nonionic PAM is used for special wastewater, like acid water or mining water.

💡 For regular sedimentation, 12 million molecular weight PAM is usually enough. There is no need to go too high.

📌 Conclusion: Pick the Right PAM for Better Results

Choosing the correct PAM flocculant is very important. The right type improves wastewater treatment results and reduces cost. Each PAM type works for different wastewater. Always test before using on a large scale. This ensures good performance and helps you find the best PAM dosage for your system.