As mining faces tighter resources and environmental rules, companies need better efficiency, lower costs, and water reuse. Polyacrylamide (PAM) plays a key role as a Flocculant in mineral processing.

Why PAM Matters in Mining

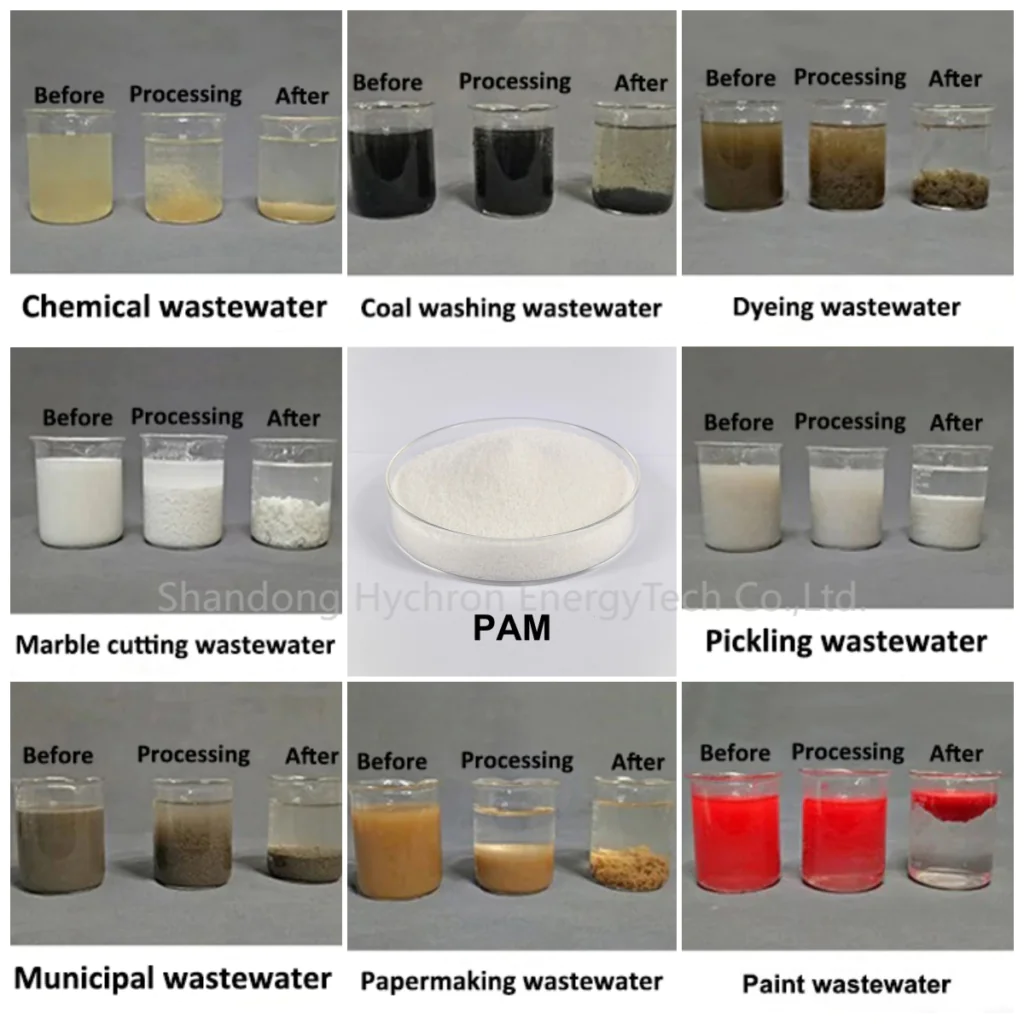

Mining uses large amounts of water to wash and separate minerals from waste rock. This creates muddy wastewater with suspended particles. PAM speeds up sludge settling, clears water for reuse, and improves sludge drying—boosting efficiency and cutting water waste.

PAM in Action: Real-World Uses

Aluminum Ore: Enhances solid-liquid separation in wastewater treatment and filtering.

Calcium Carbonate: Speeds settling in thickening processes, saving water.

Copper, Nickel, Zinc & Titanium Ores: Clears impurities faster after acid treatment, improving solution purity.

Phosphate Ore: Reduces pollutants in wastewater to meet discharge rules.

Sand, Glaze & Coal Washing: Improves settling and filtering, cutting wastewater output.

Gold Mining: Cationic PAM should be used to optimize the settling effect in acid solution and clarification.

Coal Processing: In view of the high clay content and fine suspended particles in water, weak anionic PAM (about 10% hydrolysis degree) can be selected to improve the settling effect.

Our Strength: Custom PAM Solutions

As a professional polyacrylamide manufacturer, We are well aware that different minerals and processes have different requirements for flocculants. We offer:

Anionic, Cationic & Non-Ionic PAM

Fast Clumping: Quicker settling, better separation.

Cost Savings: Less chemical use, more water recycled.

Eco-Friendly: Products meet environmental protection standards to help enterprises achieve green production.

The optimization of mineral processing technology is not only related to the economic benefits of enterprises, but also affects the sustainable development of the industry. Our PAM helps global miners cut costs, reduce waste, and meet eco-goals.

Need PAM advice for your mine? Contact us for free expert guidance!