During hot summer days, many wastewater treatment plant operators report the same problem:

👉 The aeration system is running normally,

👉 blowers are at full speed,

👉 but the DO in the aerobic tank remains low.

Why does this happen? This article summarizes five main reasons for low dissolved oxygen (DO) in summer and provides practical operation guidance.

1. High Water Temperature Reduces Oxygen Saturation

In summer, wastewater temperature often reaches 30 °C, and in some cases even close to 40 °C.

When temperature increases:

- Oxygen solubility in water decreases

- Oxygen saturation concentration becomes lower

- Oxygen transfer efficiency drops

Even with normal aeration, DO is difficult to increase under high-temperature conditions.

Operation Tip:

- Avoid excessive aeration during the hottest daytime hours

- Increase aeration during night-time

- Improve tank cooling or shading design if possible

2. Aeration Equipment Failure or Low Efficiency

If temperature is not the only reason, the aeration system itself must be checked.

Common problems include:

- Diffusers or aeration plates blocked by sludge or scale

- Blower model or air volume not suitable for current load

- Air pipelines leaking or cracked

- Uneven air distribution in the tank

Any of these issues can significantly reduce oxygen transfer efficiency.

Operation Tip:

- Perform regular inspection and maintenance

- Clean or replace diffusers in time

- Ensure stable and sufficient air supply

3. High Influent COD Increases Oxygen Demand

In summer, some industrial plants increase production.

This often leads to:

- Higher influent flow

- Higher influent COD concentration

More organic matter means microorganisms need more oxygen to degrade pollutants.

If oxygen demand increases but oxygen supply stays the same, DO will remain low.

Operation Tip:

- Strengthen influent water quality monitoring

- Adjust organic loading if possible

- Consider process optimization under high-load conditions

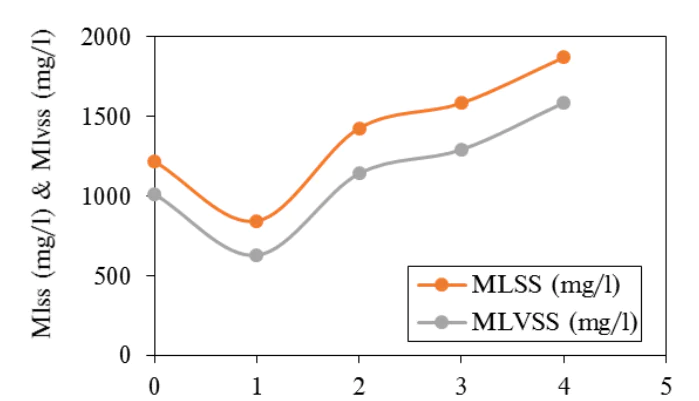

4. High Sludge Concentration in the Aerobic Tank

When MLSS is too high, the number of microorganisms increases.

Their respiration consumes large amounts of oxygen.

As a result:

- Oxygen consumption increases

- DO becomes difficult to maintain

Operation Tip:

- Discharge excess sludge in time

- Control MLSS within a reasonable range

- A common operating range is 2500–4000 mg/L

5. Improper External Return Ratio

If the sludge return ratio is too high:

- More high-concentration sludge returns to the aerobic tank

- Oxygen demand increases

- Hydraulic load rises

- Hydraulic retention time becomes shorter

These factors together reduce oxygen transfer efficiency and keep DO low.

Operation Tip:

- Adjust return ratio based on actual system load

- A common control range is 50%–100%

- Avoid excessive return that adds extra oxygen burden

Conclusion

Low DO in aerobic tanks during summer is very common, but it is also manageable.

By checking the following five aspects step by step:

- Water temperature

- Aeration equipment condition

- Influent COD level

- Sludge concentration (MLSS)

- Sludge return ratio

operators can quickly identify the real cause and take corrective actions.

With proper operation and timely adjustment, the wastewater treatment system can remain stable and effluent quality can meet discharge standards, even during hot summer conditions.