In wastewater treatment, polyaluminum chloride (PAC) and aluminum sulfate are two commonly used coagulants. Although both are aluminum-based chemicals, their molecular structures are different, which leads to clear differences in treatment efficiency, operating conditions, and overall cost.

In recent years, PAC has been increasingly adopted due to faster reaction speed and better treatment performance. Understanding the differences between these two products helps operators choose the most suitable solution for their treatment system.

Characteristics of Polyaluminum Chloride (PAC)

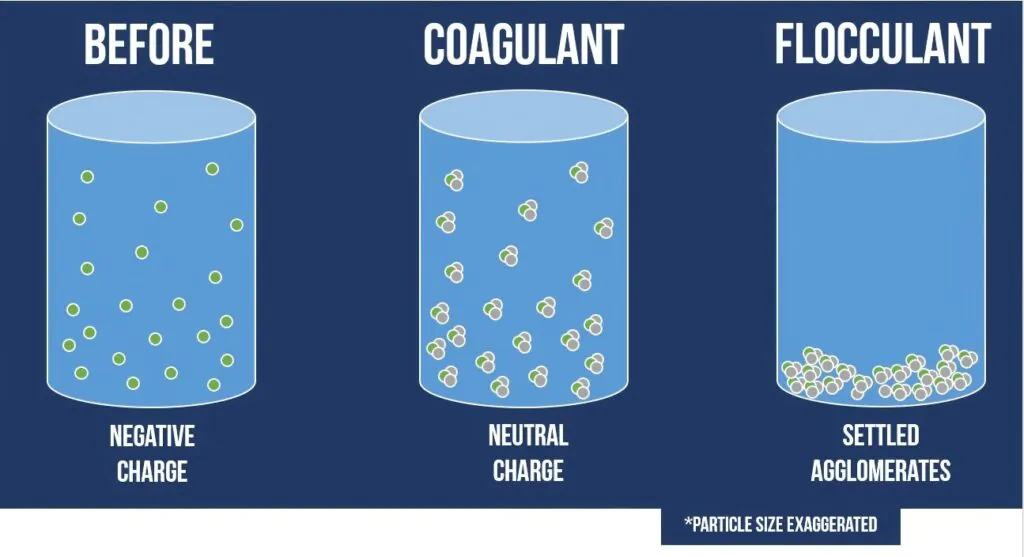

Polyaluminum chloride is an inorganic polymer coagulant with good water solubility and fast hydrolysis. After dosing, PAC quickly forms dense flocs through electric neutralization and adsorption bridging. It is often used together with polyacrylamide (PAM) to further enhance floc strength and settling speed. Compared with aluminum sulfate, PAC generally provides higher treatment efficiency and clearer effluent quality.

From a cost perspective, PAC usually reduces overall treatment cost by about 15%–30%. This is mainly due to lower dosage requirements and reduced sludge production. In addition, PAC consumes less alkalinity during the coagulation process, which means less or no need for additional alkaline agents such as lime or soda ash.

Characteristics of Aluminum Sulfate

Aluminum sulfate is a traditional coagulant that works by forming aluminum hydroxide flocs after hydrolysis. These flocs adsorb suspended solids and pollutants from wastewater. Its dissolution and hydrolysis speed are relatively slow, and it performs best within a pH range of 6.0 to 7.5.

Compared with PAC, aluminum sulfate generally has lower coagulation efficiency and produces a larger volume of sludge. It also consumes more alkalinity, which can significantly reduce the pH of treated water. As a result, neutralizing agents such as lime or soda ash are often required, increasing chemical consumption and operational complexity.

Operational Performance Comparison

From an operational point of view, PAC is easier to handle and reacts faster, allowing shorter treatment time and higher processing capacity. This makes PAC more suitable for systems that require stable performance under fluctuating water quality conditions. Aluminum sulfate hydrolyzes more slowly, which may result in longer reaction time and less flexibility during operation.

Aluminum sulfate tends to reduce both pH and alkalinity in treated water, making pH adjustment necessary in many cases. PAC solutions are closer to neutral and typically do not require additional pH correction, which simplifies daily operation and reduces equipment corrosion risks.

Storage and Equipment Impact

Both PAC and aluminum sulfate are generally stable and easy to store and transport. PAC should be kept sealed to avoid moisture absorption and prolonged exposure to sunlight. In terms of corrosivity, aluminum sulfate is more aggressive to pipelines and dosing equipment, especially under acidic conditions. This factor should be considered when selecting materials for long-term operation.

Which Coagulant Should You Choose?

Both polyaluminum chloride and aluminum sulfate have their own application scenarios. PAC is increasingly becoming the mainstream choice due to its high efficiency, rapid coagulation speed, wide pH adaptability, and lower overall operating cost. Aluminum sulfate still plays a role in specific cases where water conditions are stable and cost sensitivity is high.

In practical wastewater treatment projects, selecting the right coagulant should be based on raw water quality, treatment targets, operating cost, and system stability. A suitable choice can significantly improve treatment efficiency and reduce long-term operational expenses.

If you are evaluating PAC or aluminum sulfate for your wastewater treatment system, we can help you compare grades, dosage strategies, and cost performance based on your actual water conditions. Feel free to contact us for technical support and product recommendations.