In practical water treatment plants, polyacrylamide flocculant is mainly applied on-site to enhance physical separation processes, helping operators achieve stable performance and water reuse.

what is polyacrylamide flocculant

Application 1: Sedimentation Systems

When used in sedimentation tanks, PAM accelerates the aggregation of suspended solids into dense flocs.

Operators should observe:

- Reaction speed after dosing

- Floc size and settling rate

- Effluent clarity

Proper dosing improves tank efficiency and reduces hydraulic retention time.

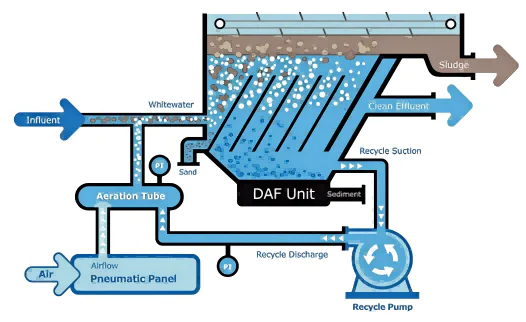

Application 2: Air Flotation Units

In dissolved air flotation (DAF), PAM improves floc–bubble attachment.

Key indicators include:

- Floc suspension height

- Floating speed

- Surface sludge thickness

Correct polymer selection prevents carryover and improves treated water quality.

Application 3: Sludge Dewatering

Sludge dewatering is one of the most important uses of polyacrylamide flocculant.

Performance is evaluated by:

- Floc structure and strength

- Sludge cake moisture content

- Filtrate clarity

Well-selected PAM significantly reduces sludge volume and disposal cost.

Why Different Processes Need Different PAM Types

Sedimentation, flotation, and dewatering operate under different conditions. Polymer type, molecular weight, and charge density must be matched to the process and sludge characteristics to avoid overdosing or poor flocculation.

factors affecting flocculant performance

Conclusion

Polyacrylamide flocculant improves water treatment efficiency by enhancing sedimentation, flotation, and sludge dewatering. Selecting the right PAM grade is critical for achieving both technical stability and economic benefits.