Description

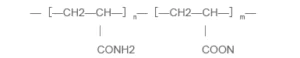

Anionic Polyacrylamide (APAM)

Chemical Formula

Actions Principle

-

Adsorption: APAM is adsorbed on the surface of suspended particles, making the particles negatively charged. This charge repels particles from each other, enhancing dispersion and aiding in water treatment.

-

Polymer Chain Bridging: APAM’s polymer chains connect suspended together, so that they condence into larger flocs. This process accelerates the precipitation or filtration of particles.

Features

-

Negative Charge: it has a negative charge, can neutralize positively charged suspended particles, promoting rapid settling.

-

High Molecular Weight, good flocculation performance: Effectively removes suspended substances and colloidal substances in the water, resulting in high water clarity after treatment.

-

Wide pH and Temperature Range: APAM performs consistently well across a pH range of 5–14 and handles a variety of temperatures, making it reliable for different conditions.

-

Good Compatibility with Inorganic Coagulants: APAM works great with coagulants like polyferric sulfate, polyaluminum chloride, and iron salts, helping to improve overall treatment efficiency.

Technical Parameters

|

No.

|

Items

|

Specifications

|

|

1

|

Appearance

|

White Powder

|

|

2

|

Solid Content (%)

|

≥88

|

|

3

|

Molecular Weight (Million)

|

12-30

|

|

4

|

Degree Of Ion (%)

|

Low Medium High

|

|

5

|

Dissolving Time (Min)

|

≤60

|

Hot Sell Types

| Model | Physical Form | Solid Content (N≥) | Dissolution Time (W≤) | Degree Of Hydrolysis | Molecular Weight (Ten Thousand) |

| 1810 | Granules | 90% | 90 Minutes | 10 | 1000-1200 |

| 1815 | Granules | 90% | 90 Minutes | 15 | 1400-1500 |

| 1825 | Granules | 90% | 60 Minutes | 20-25 | 1600-1800 |

| 1826 | Granules | 90% | 60 Minutes | 25 | 1600-1800 |

| 1860 | Granules | 90% | 60 Minutes | 20-25 | 1600-1800 |

| 1880 | Granules | 90% | 60 Minutes | 25-30 | 1300-1500 |

| 1890 | Granules | 90% | 60 Minutes | 27-33 | 600-800 |

| 1920 | Granules | 90% | 90 Minutes | 0 | 400-600 |

| Special For Incense Making | Granules | 90% | 90 Minutes | 28-35 | 2000-2500 |

| Oilfield Dedicated | Granules | 90% | 90 Minutes | 28-35 | 2200-2500 |

| M135 | Granules | 90% | 60 Minutes | 20-23 | 1400 |

| 9060 | Granules | 90% | 90 Minutes | W5 | 800-1200 |

| 9160 | Granules | 90% | 90 Minutes | 15-20 | 600-2200 |

| 9260 | Granules | 90% | 90 Minutes | 23-28 | 600-2200 |

| 9360 | Granules | 90% | 90 Minutes | 28-32 | 1800-2200 |

APAM Types And Classifications

-

Hydrolysis Degree: APAM is available in low (5-15%), medium (23-27%), and high (28-35%) hydrolysis degrees, which affect price and performance.

-

Molecular Weight: Ranges from 8 million to 25 million. Higher molecular weights increase viscosity, reduce dosage, and improve performance.

-

Mesh Size: The higher the mesh number, the quicker the product dissolves.

Applications

-

Textile and Dyeing Industry: APAM works as a sizing and finishing agent, making fabrics wrinkle-resistant, soft, and mildew protection. Its strong moisture-absorbing ability helps reduce fiber breakage during spinning. As a post-treatment agent, it prevents static and adds flame resistance. In dyeing, it improves dye adhesion, enhancing vibrancy and color, and acts as a non-silicone stabilizer during bleaching.

-

Flocculation for Industrial Wastewater: APAM is great for treating wastewater with suspended particles, especially those with positive charges in neutral or alkaline water. It helps bind solids into larger flocs, making them easier to settle and filter. It’s widely used in coal washing, metallurgy, electronics, and municipal wastewater treatment.

-

Petroleum Industry: PAM is used in the petroleum industry to improve oil recovery, reduce friction in drilling, prevent water migration, treat waste drilling mud, and enhance the efficiency of tertiary oil recovery.

-

Papermaking Industry: APAM helps paper factory to keep more fillers and pigments in the paper, reducing waste and pollution. It also strengthens paper, improves paper tear resistance, wet and dry strength, and print quality. This makes it especially valuable in producing packaging paper, like food and tea.

-

Sugar production: PAM is used to clarify the cane and beet juice. PAM helps remove the impurities and separate the syrup from unwanted solids, improving the quality of the final product. It also helps with the separation process during syrup production.

-

Animal Feed: PAM is used in the recovery of protein from animal feed. By helping to separate protein from other components, it improves the quality of the recovered protein, which in turn boosts animal health, weight gain, and egg production.

-

Other Industries: In industries like synthetic resins, cement, adhesives, soil stabilization, electroplating, textile printing and dyeing, and construction materials, PAM is used for various purposes like enhancing material properties (strength, stability), improving process efficiency, and reducing waste or pollution. It helps bind materials, control fluid flow, and improve the final product’s quality.

Function in Different Industries

|

Industry

|

Application

|

|

Sugar Production

|

Sugar Juice Purification

|

|

Syrup Filtration

|

|

|

Salt Production

|

Clarification Of Brine For Removal Of Calcium And Magnesium Ions

|

|

Adhesives

|

Replacement Of 1799 Or Animal Glue Paper Labels Or Adhesive Labels

|

|

Coatings

|

Increase Viscosity

|

|

Industrial Wastewater Treatment

|

Physical And Chemical Treatment

|

|

Drinking Water

|

Improve Treatment Efficiency

|

|

Petroleum Extraction

|

Enhanced Oil Recovery (EOR)

|

|

Drilling Fluid Treatment

|

|

|

Water Shutoff Agent Preparation

|

|

|

Steel Industry

|

Gas Scrubbing For Blowers

|

|

Steelmaking Wastewater Treatment

|

|

|

Copper Mining

|

Acid Leach Filtration

|

|

Cyanide Process

|

Gold Extraction

|

|

Pulp And Paper

|

Filler And Fiber Retention

|

|

Increase Paper Strength

|

|

|

Paper Mill Wastewater Treatment

|

|

|

Coal Washing

|

Coal Washing Slurry Concentration And Filtration

|

|

Coal Slime Settling

|

|

|

Coal Washing Wastewater

|

|

|

Textile Industry

|

Dye Thickening And Sizing

|

How to Choose the Right Anionic Polyacrylamide (APAM)

-

For Neutral or Weak Alkaline Water (pH ≈ 7):

-

Pre-Treatment Stage (Before Flotation Equipment):

-

For Inorganic Wastewater Coagulation and Settling:

-

For Thickening and Viscosity:

Usage

-

Dissolving

-

Add APAM dry powder into water slowly, while stirring until it dissolves completely.

-

Stir for 30-60 minutes.

-

Use low hardness water. Not use metal tanks or containers which could affect water quality.

-

Use tempered water to speed up dissolving process if needed, noted that water temperature should below 50°C.

-

Diluting

-

After dissolved, dilute the APAM solution to the desired concentration.

-

The usual dilution ratio is between 1:10 and 1:100.

-

Adding

-

Adjusting

Packaging and loading

Storage and Precautions

-

This product is non-toxic, easily dissolves in water, and may clump when exposed to moisture.

-

If it comes into contact with skin, wash it off immediately with water.

-

The recommended storage temperature is between 5°C and 40°C. It should be stored in a dry place.

Reviews

There are no reviews yet.