Temperature is a key operational factor that directly affects the performance of Polyaluminum Chloride (PAC) during water and wastewater treatment. In low-temperature and low-turbidity conditions, PAC flocculation efficiency can decrease significantly.

Understanding this impact helps plant operators adjust dosage, mixing, and process design—especially during winter operation.

1. Why Temperature Matters for PAC Flocculation

PAC is an inorganic polymer coagulant. Its performance depends on:

- Molecular activity

- Hydrolysis rate

- Particle collision efficiency

Temperature directly influences all these factors.

Under normal operating conditions, PAC molecules remain active and stable, allowing effective adsorption, charge neutralization, and floc formation.

👉 Related article: What Affects the Performance of Flocculants?

2. Optimal Temperature Range for PAC

Based on molecular structure behavior, PAC performs best within a temperature range of 5°C to 20°C.

Within this range:

- PAC molecules remain active

- Hydrolysis reactions proceed smoothly

- Flocs form quickly and settle well

- Adsorption and bridging effects are stable

This is why most PAC-based systems are designed assuming moderate temperatures.

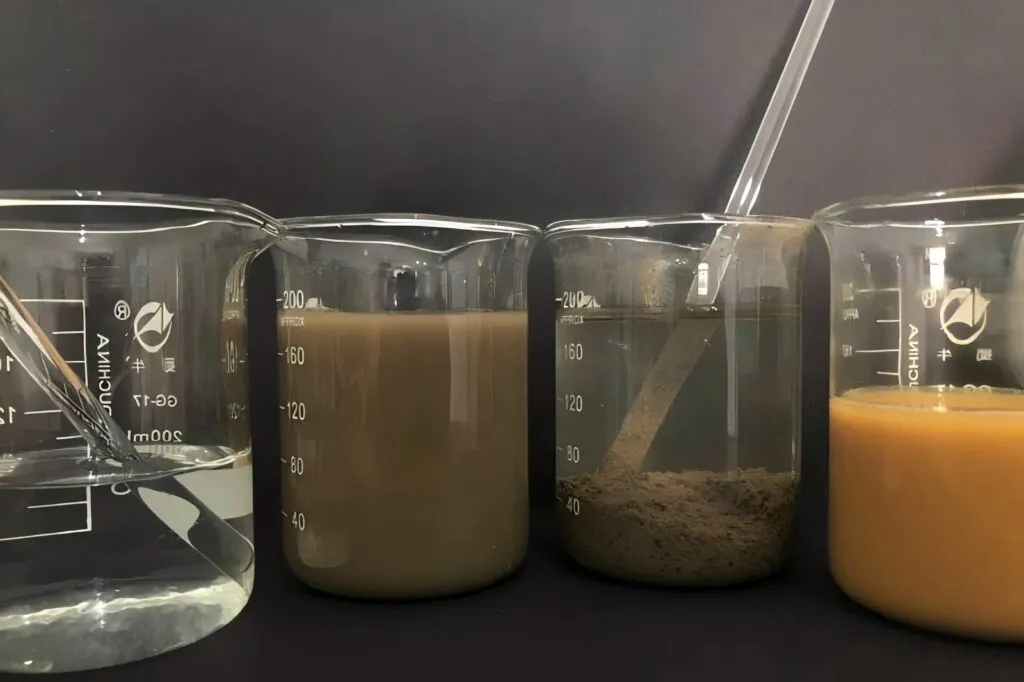

3. What Happens to PAC at Low Temperature?

When temperature drops close to or below 0°C, PAC performance is clearly affected.

Key impacts include:

- Reduced molecular movement

- Slower hydrolysis reactions

- Weak charge neutralization

- Poor adsorption efficiency

As a result:

- Flocs form slowly or not at all

- Floc size becomes smaller and loose

- Sedimentation efficiency decreases

In extreme cases, flocculation may fail completely.

4. Why PAC Performs Poorly in Winter Conditions

In winter, many regions experience temperatures below freezing.

Under these conditions:

- PAC molecules shift from an active state to a semi-suspended state

- Particle collisions decrease

- Adsorption and precipitation become ineffective

This explains why operators often observe:

- Cloudy effluent

- Longer settling time

- Increased chemical consumption

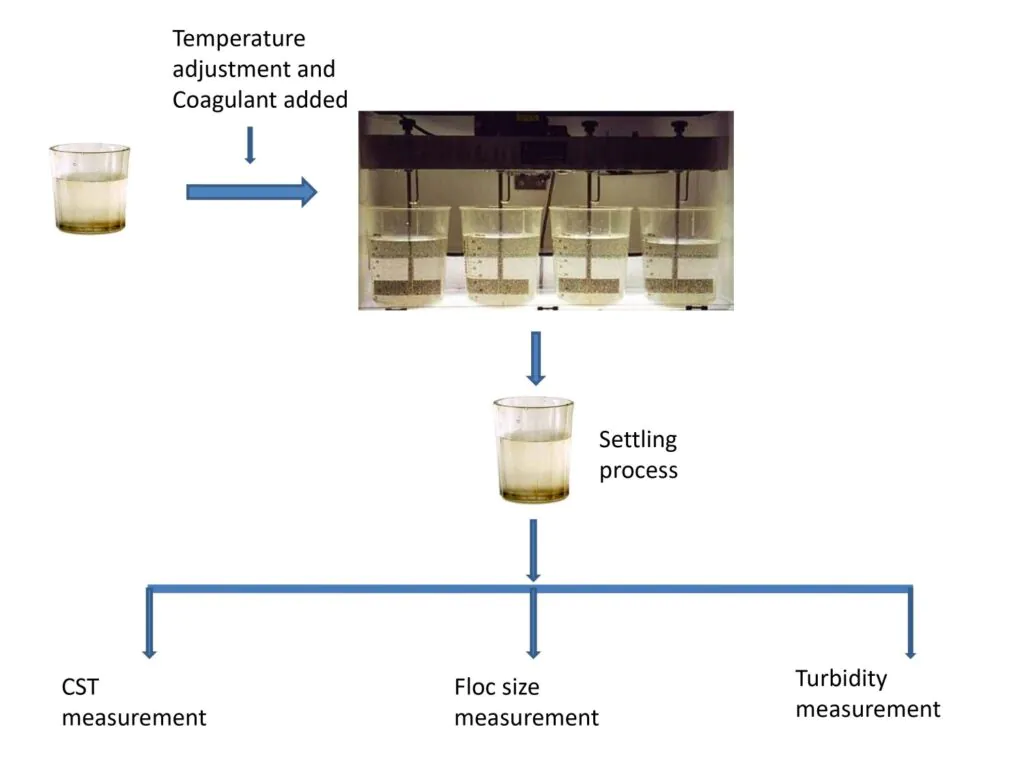

5. How to Improve PAC Performance at Low Temperature

To maximize PAC efficiency in cold environments, several measures can be taken:

- Increase mixing intensity during the rapid mixing stage

- Extend reaction and flocculation time

- Adjust PAC dosage carefully through jar testing

- Combine PAC with suitable polymer flocculants

- Maintain solution temperature if possible

Conclusion

Temperature has a significant and direct impact on PAC performance. Below 0°C, reduced molecular activity leads to poor floc formation, weak adsorption, and inefficient sedimentation.

For stable treatment results, temperature must be considered alongside:

- pH control

- Dosage optimization

- Mixing conditions

- Flocculant selection

Proper adjustment ensures PAC continues to deliver reliable results—even in winter operation.