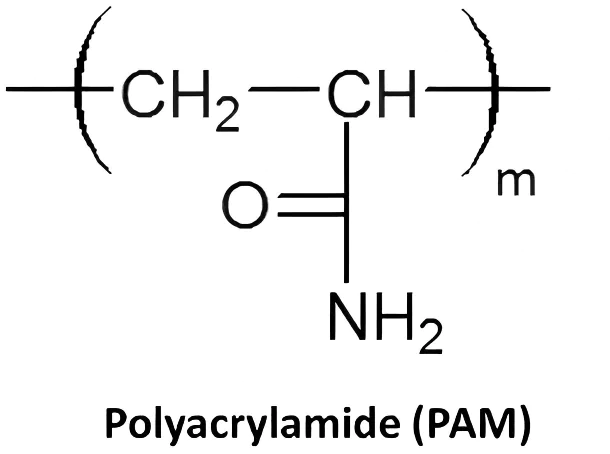

Polyacrylamide flocculant, commonly known as PAM, is a water-soluble polymer made from acrylamide monomers. It can be produced as a homopolymer or as a copolymer combined with other functional monomers to meet different treatment needs.

Because of its strong flocculation ability and wide adaptability, polyacrylamide flocculant is widely used in oil extraction, papermaking, textiles, agriculture, and especially water and wastewater treatment, where it plays a key role in solid–liquid separation.

How Polyacrylamide Flocculant Works

In water, suspended particles usually carry surface charges that keep them dispersed. Polyacrylamide flocculant works through:

- Charge neutralization – reducing repulsive forces between particles

- Polymer bridging – long molecular chains link fine particles together

- Floc growth – small particles form larger, stronger flocs

These flocs are easier to settle, float, or separate mechanically.

how PAM improves wastewater treatment efficiency

Why PAM Is Preferred in Water Treatment

Compared with inorganic coagulants alone, polyacrylamide flocculant offers:

- High efficiency at low dosage

- Fast reaction and floc formation

- Improved effluent clarity

- Strong adaptability to different water qualities

For buyers and operators, PAM is often selected as a performance enhancer rather than a standalone chemical.

optimize polyacrylamide flocculant performance

Conclusion

Polyacrylamide flocculant is a core chemical in modern water treatment systems. Its ability to aggregate fine particles efficiently makes it essential for sedimentation, flotation, and sludge dewatering processes.