Livestock and poultry farming generates large volumes of high-strength wastewater. If not properly treated, this wastewater can cause serious pollution to soil, surface water, and groundwater.

Polyaluminium Chloride (PAC) has become a key chemical in livestock and poultry wastewater treatment due to its strong flocculation ability, stable performance, and cost efficiency.

Characteristics of Livestock and Poultry Wastewater

Wastewater from pig farms, chicken farms, cattle farms, and duck farms typically contains:

- Extremely high COD and BOD

- High ammonia nitrogen from manure and urine

- High phosphorus concentration

- Suspended solids, fats, and colloidal organic matter

- Strong odor and dark color

These characteristics make direct biological treatment unstable and inefficient without proper pretreatment.

👉 Related background: The Role of PAC in Agricultural Wastewater Treatment

Why PAC Is Suitable for Livestock and Poultry Wastewater

PAC is a high-polymer inorganic flocculant that forms stable polynuclear aluminum complexes in water.

These complexes provide:

- Strong charge neutralization

- Rapid adsorption of organic particles

- Efficient flocculation and sedimentation

Unlike traditional aluminum sulfate, PAC causes minimal pH fluctuation, which is critical for downstream anaerobic and aerobic biological systems.

Key Pollutant Removal Performance of PAC

1. COD and BOD Reduction

PAC aggregates organic matter, suspended solids, and colloidal particles, allowing them to settle or float for removal.

This significantly reduces COD and BOD loading before biological treatment.

2. Phosphorus Removal

PAC reacts with phosphate ions to form insoluble aluminum phosphate, achieving efficient phosphorus removal.

3. Ammonia Nitrogen Control (Indirect Effect)

PAC does not directly oxidize ammonia nitrogen, but it:

- Removes particulate-bound nitrogen

- Improves biodegradability

- Stabilizes influent conditions

This enhances the performance of subsequent nitrification and denitrification processes.

Typical Treatment Process Using PAC

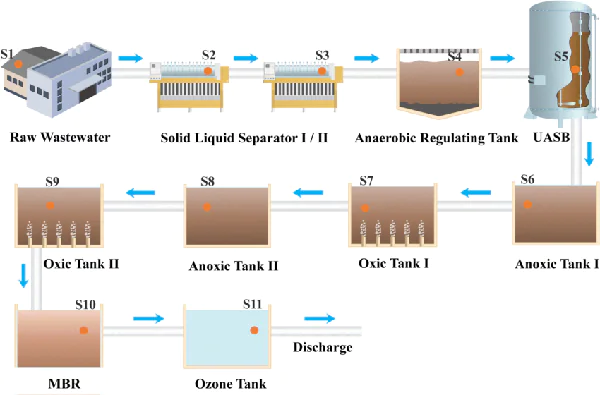

In livestock and poultry wastewater systems, PAC is usually applied at the pretreatment stage:

- Screening and grit removal

- PAC dosing and rapid mixing

- Flocculation and sedimentation or air flotation

- Biological treatment (UASB, anaerobic tank, aerobic tank)

- Sludge dewatering

PAC helps protect biological units from shock loads and toxic inhibition.

Advantages of PAC in Farm-Scale and Industrial Farms

PAC offers several advantages for livestock wastewater treatment:

- Low dosage with high efficiency

- Simple operation, suitable for farm-scale systems

- Low corrosion to pipelines and equipment

- Reduced sludge volume compared with traditional coagulants

- Stable performance under fluctuating water quality

These benefits make PAC suitable for both small farms and large-scale breeding operations.

Practical Procurement Considerations

When purchasing PAC for livestock and poultry wastewater treatment, decision-makers should evaluate:

- Al₂O₃ content and polymerization degree

- Insoluble matter content

- Batch-to-batch stability

- Supplier support for jar testing and process optimization

Choosing the right PAC grade ensures:

- Stable discharge compliance

- Lower operating and maintenance costs

👉 Product selection reference: How to Choose the Right PAC for Wastewater Treatment

Conclusion

PAC plays a critical role in livestock and poultry wastewater treatment by effectively removing COD, phosphorus, suspended solids, and stabilizing influent conditions for biological treatment.

Its high efficiency, low dosage, and operational stability make PAC a preferred pretreatment chemical for modern livestock and poultry farming operations aiming to meet environmental regulations.