In modern papermaking, single-chemical solutions are often not enough to meet today’s demands for high speed, stable quality, and low cost. As a result, many paper mills now apply PAC (Polyaluminium Chloride) together with PAM (Polyacrylamide) to optimize wet-end chemistry.

This article explains how PAC and PAM work together, why their combination is more effective than using either alone, and how paper mills can apply them correctly.

Why Combine PAC and PAM in Papermaking?

PAC and PAM play different but complementary roles:

- PAC mainly acts as a coagulant and sizing aid

- PAM mainly acts as a flocculant and retention aid

When used together, they form a coagulation–flocculation system that improves overall papermaking performance.

👉 For PAC fundamentals, see Can PAC Be Used as a Papermaking Additive?

Different Roles of PAC and PAM in the Wet-End System

Role of PAC in Papermaking

PAC provides:

- Charge neutralization

- Sizing enhancement

- Improved filler fixation

- pH stability in acidic and neutral systems

PAC creates a favorable chemical environment for further flocculation.

Role of PAM in Papermaking

PAM provides:

- Long-chain bridging between fibers and fillers

- Floc size control

- Improved retention and drainage

👉 Learn more about PAM fundamentals in Polyacrylamide (PAM) Application in Papermaking

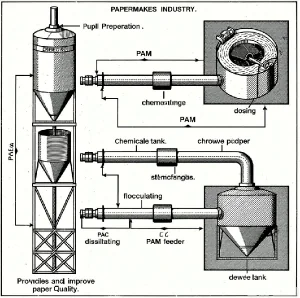

How PAC and PAM Work Together (Mechanism Explained)

The synergy happens in two stages:

Stage 1: Charge Neutralization by PAC

- Fibers, fines, and fillers are usually negatively charged

- PAC neutralizes excess negative charges

- Colloidal stability is reduced

This step prevents over-dispersion and prepares the system.

Stage 2: Floc Formation by PAM

- PAM bridges neutralized particles

- Strong, uniform flocs are formed

- Flocs resist shear in high-speed paper machines

Key Benefits of PAC + PAM Combination

1. Higher Retention of Fibers and Fillers

- Less fiber loss to white water

- Better calcium carbonate retention

- Reduced raw material consumption

2. Improved Drainage and Dewatering

- Faster water removal on wire section

- Higher machine speed potential

- Lower drying energy consumption

👉 Related topic: PAC in Paper Mill Wastewater Treatment

3. More Stable Sizing Performance

- Reduced AKD/ASA sizing fluctuation

- Lower risk of sizing loss and slippage

- Better sizing uniformity

4. Cleaner White Water System

- Reduced suspended solids

- Lower COD in white water

- Easier water recycling

Practical Dosing Strategy for Paper Mills

Typical Dosing Sequence

- PAC is added first (coagulation stage)

- PAM is added later (flocculation stage)

Correct dosing sequence is critical to synergy.

General Dosage Range (Reference)

- PAC: depends on pulp type and filler load

- PAM: low dosage, high efficiency

⚠ Always confirm via lab trials before full-scale application.

Common Problems and How to Avoid Them

| Problem | Cause | Solution |

|---|---|---|

| Over-flocculation | Excess PAM | Reduce dosage, adjust shear |

| Poor retention | PAC underdosing | Increase PAC slightly |

| Drainage slowdown | Wrong PAM type | Change molecular weight |

Procurement Considerations for PAC and PAM

When sourcing PAC and PAM for papermaking, buyers should evaluate:

- Aluminum content and iron level (PAC)

- Molecular weight and charge density (PAM)

- Product consistency between batches

- Technical support and lab testing capability

Low price alone should not be the main selection factor.

Conclusion

Using PAC and PAM together creates a balanced and efficient wet-end chemistry system.

Their synergy helps paper mills:

- Improve retention and drainage

- Stabilize sizing

- Reduce chemical and energy costs

- Maintain consistent paper quality

For modern papermaking operations, PAC + PAM is no longer optional, but a proven optimization strategy.